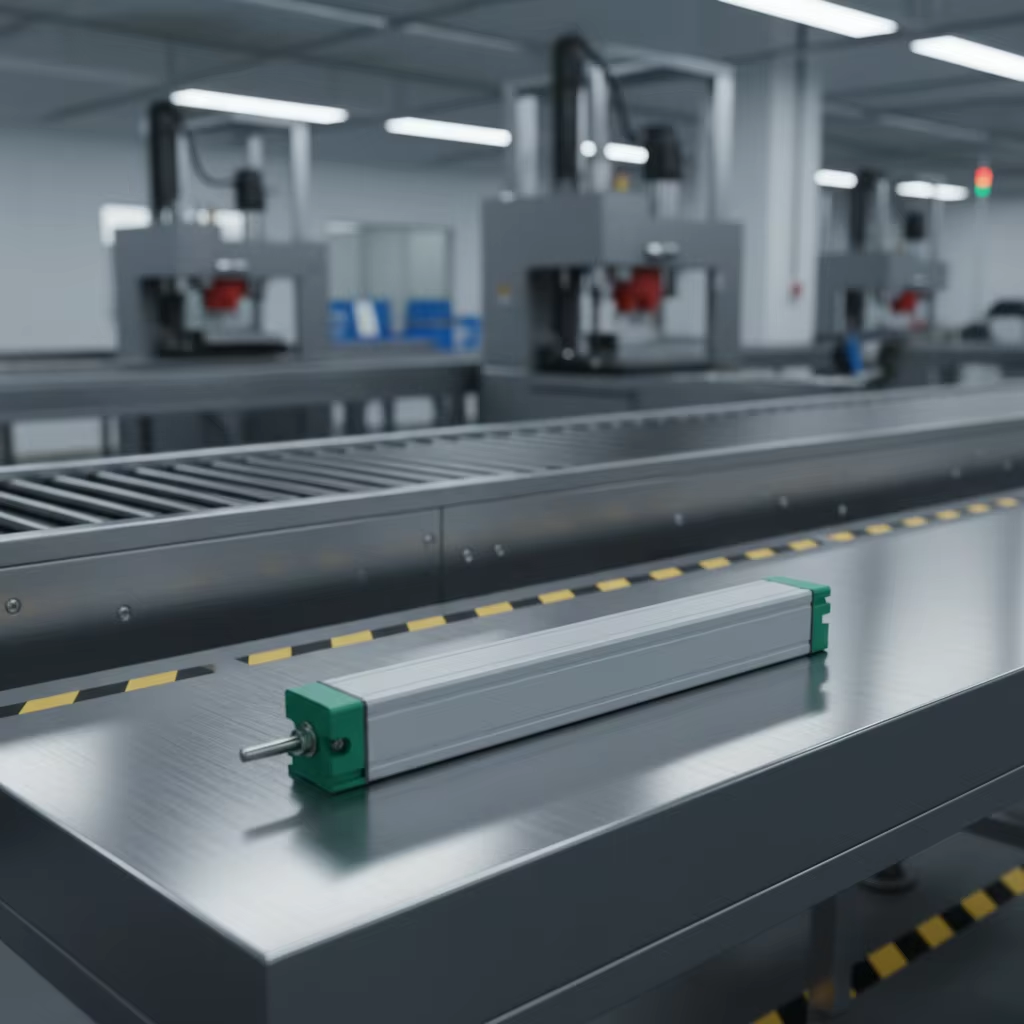

दुनिया भर में विनिर्माण सुविधाएं अपनी उत्पादन लाइनों में गुणवत्ता नियंत्रण और संचालन दक्षता बनाए रखने के लिए सटीक माप प्रौद्योगिकी पर निर्भर करती हैं। आधुनिक औद्योगिक प्रक्रियाओं में उन्नत सेंसिंग उपकरणों के आवेदन को आवश्यक बना दिया गया है, जहां सटीकता और विश्वसनीयता सीधे उत्पाद की गुणवत्ता और समग्र उत्पादकता को प्रभावित करती है। आज उपलब्ध सबसे महत्वपूर्ण माप उपकरणों में, लीनियर डिस्प्लेसमेंट सेंसर स्वचालित प्रणालियों में स्थिति, गति और आयामी परिवर्तन की निगरानी के लिए एक मौलिक घटक के रूप में उभरा है।

इन उन्नत मापन उपकरणों की स्थापना प्रक्रिया के लिए अनुकूलतम प्रदर्शन और दीर्घायु को सुनिश्चित करने हेतु सावधानीपूर्वक योजना, उचित तकनीकी ज्ञान और उद्योग के सर्वोत्तम प्रथाओं का पालन आवश्यक होता है। उत्पादन लाइन एकीकरण में यांत्रिक माउंटिंग, विद्युत संयोजन, पर्यावरणीय सुरक्षा और परिशुद्धता के साथ किए जाने वाले कैलिब्रेशन प्रक्रियाओं सहित कई बातों पर विचार करना शामिल है ताकि भरोसेमंद संचालन प्राप्त किया जा सके।

रैखिक विस्थापन सेंसर तकनीक की समझ

मुख्य संचालन सिद्धांत

रैखिक विस्थापन सेंसर विभिन्न तकनीकी सिद्धांतों पर काम करते हैं, जिनमें से प्रत्येक विशिष्ट औद्योगिक अनुप्रयोगों के लिए अलग-अलग लाभ प्रदान करता है। सबसे आम प्रकारों में पोटेंशियोमेट्रिक सेंसर शामिल हैं, जो स्थिति परिवर्तन के अनुपात में वोल्टेज संकेत उत्पन्न करने के लिए प्रतिरोधक तत्वों का उपयोग करते हैं, और मैग्नेटोस्ट्रिक्टिव सेंसर जो सटीक स्थिति डेटा निर्धारित करने के लिए चुंबकीय क्षेत्र परिवर्तन का उपयोग करते हैं। ये उपकरण यांत्रिक विस्थापन को विद्युत संकेतों में परिवर्तित करते हैं जिन्हें नियंत्रण प्रणालियों और डेटा अधिग्रहण उपकरणों द्वारा संसाधित किया जा सकता है।

आधुनिक सेंसर डिज़ाइन अत्यधिक सटीकता के स्तर प्राप्त करने के लिए उन्नत सामग्री और निर्माण तकनीकों को शामिल करते हैं, जो अक्सर विशिष्ट मॉडल और अनुप्रयोग आवश्यकताओं के आधार पर माइक्रोमीटर या उससे बेहतर के संकल्प तक पहुँच जाते हैं। संकेत आउटपुट विशेषताएँ एनालॉग वोल्टेज आउटपुट, डिजिटल संचार प्रोटोकॉल और विशेष इंटरफ़ेस मानकों के बीच भिन्न होती हैं जो मौजूदा उत्पादन लाइन नियंत्रण प्रणालियों के साथ संगत होने चाहिए।

गुणवत्तापूर्ण सेंसरों में निर्मित तापमान क्षतिपूर्ति तंत्र औद्योगिक सेटिंग्स में सामान्यतः पाए जाने वाले विभिन्न पर्यावरणीय परिस्थितियों में मापन स्थिरता सुनिश्चित करते हैं। यह विशेषता विशेष रूप से महत्वपूर्ण हो जाती है जब सेंसर ऐसे वातावरण में काम करते हैं जहाँ उल्लेखनीय तापमान उतार-चढ़ाव हो सकता है, जो अन्यथा मापन की शुद्धता और प्रणाली की विश्वसनीयता को प्रभावित कर सकता है।

अनुप्रयोग-विशिष्ट विचार

विभिन्न उत्पादन लाइन अनुप्रयोगों को माप सीमा, रिज़ॉल्यूशन, प्रतिक्रिया समय और पर्यावरणीय प्रतिरोध क्षमता सहित विशिष्ट सेंसर विशेषताओं की आवश्यकता होती है। असेंबली लाइन संचालन में तेजी से गति करने वाले घटकों को ट्रैक करने के लिए त्वरित प्रतिक्रिया समय वाले सेंसर की आवश्यकता हो सकती है, जबकि गुणवत्ता नियंत्रण स्टेशनों को सटीक आयामी माप के लिए गति की तुलना में अधिकतम शुद्धता को प्राथमिकता देनी हो सकती है।

सेंसर का भौतिक आकार और माउंटिंग विन्यास रैखिक विस्थापन सेंसर उत्पादन वातावरण के भीतर उपलब्ध स्थापना स्थान और यांत्रिक सीमाओं के साथ संरेखित होना चाहिए। संकुचित स्थानों में एकीकरण को सुगम बनाने के लिए संक्षिप्त डिज़ाइन की आवश्यकता होती है, जबकि मजबूत निर्माण कठिन औद्योगिक परिस्थितियों जैसे कंपन, झटके और दूषण के संपर्क के तहत विश्वसनीय संचालन सुनिश्चित करता है।

संकेत प्रसंस्करण क्षमता और संचार अंतरापृष्ठ यह निर्धारित करते हैं कि सेंसर डेटा को मौजूदा स्वचालन प्रणालियों, प्रोग्रामेबल लॉजिक कंट्रोलर्स और डेटा संग्रह नेटवर्क के साथ कितनी प्रभावी ढंग से एकीकृत किया जा सकता है। मानक औद्योगिक संचार प्रोटोकॉल के साथ संगतता सुचारु एकीकरण को सक्षम करती है और रखरखाव कर्मी तथा प्रणाली एकीकर्ताओं के लिए लागूकरण की जटिलता को कम करती है।

पूर्व-स्थापना योजना और मूल्यांकन

स्थल सर्वेक्षण और आवश्यकता विश्लेषण

व्यापक साइट मूल्यांकन सफल सेंसर स्थापना परियोजनाओं का आधार बनता है, जिसमें यांत्रिक माउंटिंग स्थानों, विद्युत बुनियादी ढांचे की उपलब्धता और वातावरणीय स्थितियों का विस्तृत आकलन आवश्यक होता है जो सेंसर प्रदर्शन को प्रभावित कर सकती हैं। उत्पादन लाइन लेआउट विश्लेषण उन आदर्श सेंसर स्थापना बिंदुओं की पहचान करता है जो सटीक माप डेटा प्रदान करते हैं, साथ ही सामान्य संचालन और रखरखाव गतिविधियों में हस्तक्षेप को न्यूनतम करते हैं।

माप सीमा आवश्यकताओं की सावधानीपूर्वक गणना करनी चाहिए ताकि सुनिश्चित किया जा सके कि चयनित सेंसर सामान्य संचालन और संभावित अतिरिक्त यात्रा स्थितियों के लिए उचित सुरक्षा मार्जिन के साथ पर्याप्त यात्रा दूरी प्रदान करें। अपेक्षित विस्थापन पैटर्न, गति और आवृत्तियों को समझने से प्रत्येक अनुप्रयोग के लिए सबसे उपयुक्त सेंसर तकनीक और प्रदर्शन विशिष्टताओं का निर्धारण करने में मदद मिलती है।

पर्यावरणीय मूल्यांकन में तापमान सीमा, आर्द्रता स्तर, कंपन विशेषताओं, विद्युत चुम्बकीय हस्तक्षेप स्रोतों और संभावित संदूषण के संपर्क का आकलन शामिल है जो सेंसर संचालन को प्रभावित कर सकते हैं। यह जानकारी उपयुक्त सुरक्षात्मक उपायों और सेंसर विन्यासों के चयन का मार्गदर्शन करती है जो विशिष्ट संचालन वातावरण में दीर्घकालिक विश्वसनीयता सुनिश्चित करते हैं।

प्रणाली एकीकरण योजना

विद्युत बुनियादी ढांचे के मूल्यांकन में बिजली आपूर्ति आवश्यकताओं, सिग्नल मार्ग संबंधी पथों और नियंत्रण प्रणाली इंटरफ़ेस विनिर्देशों को शामिल किया जाता है जिन्हें स्थापना योजना के दौरान संबोधित करना आवश्यक है। रैखिक विस्थापन सेंसर की बिजली खपत विशेषताओं को उपलब्ध विद्युत क्षमता के अनुरूप होना चाहिए, जबकि सिग्नल अखंडता पर विचार केबल प्रकारों और मार्ग संबंधी विधियों का निर्धारण करते हैं।

नियंत्रण प्रणाली संगतता विश्लेषण यह सुनिश्चित करता है कि चयनित सेंसर उपलब्ध नियंत्रकों, डेटा अधिग्रहण प्रणालियों या विशेष निगरानी उपकरणों की इनपुट आवश्यकताओं के अनुरूप आउटपुट संकेत प्रदान करते हैं। संकेत प्रसंस्करण की आवश्यकताओं के कारण उचित संकेत स्तर और शोर प्रतिरोधकता प्राप्त करने के लिए अतिरिक्त इंटरफ़ेस मॉड्यूल या एम्पलीफायर की आवश्यकता हो सकती है।

दस्तावेज़ीकरण आवश्यकताओं में स्थापना ड्राइंग, वायरिंग आरेख और कैलिब्रेशन प्रक्रियाओं का निर्माण शामिल है जो उचित स्थापना और भविष्य के रखरखाव क्रियाओं को सुगम बनाता है। व्यापक दस्तावेज़ीकरण समस्या निवारण प्रयासों का समर्थन करता है और कई सेंसरों और उत्पादन लाइन स्थानों में सुसंगत स्थापना प्रथाओं को सुनिश्चित करता है।

यांत्रिक स्थापना प्रक्रियाएं

माउंटिंग हार्डवेयर और फिक्सचर

उचित यांत्रिक माउंटिंग सटीक मापन प्रदर्शन सुनिश्चित करता है और संचालन के दौरान अत्यधिक बलों या गलत संरेखण की स्थिति से सेंसर को होने वाले नुकसान को रोकता है। माउंटिंग ब्रैकेट के डिज़ाइन को ऊष्मीय प्रसार और सामान्य यांत्रिक विक्षेप को समायोजित करते हुए भी दृढ़ सहारा प्रदान करना चाहिए, बिना मापन त्रुटियों या तनाव संकेंद्रण को उत्पन्न किए जो सेंसर के लंबे जीवन पर प्रभाव डाल सकते हैं।

संरेखण प्रक्रियाओं के लिए निगरानी किए जा रहे गतिशील घटकों के सापेक्ष उचित सेंसर अभिविन्यास प्राप्त करने के लिए सटीक उपकरण और मापन उपकरण की आवश्यकता होती है। कोणीय गलत संरेखण मापन त्रुटियाँ उत्पन्न कर सकता है और सेंसर घटकों पर यांत्रिक घर्षण में वृद्धि कर सकता है, विशेष रूप से उन अनुप्रयोगों में जिनमें उच्च-गति या उच्च-आवृत्ति गतिविधियाँ शामिल होती हैं।

गार्ड, शील्ड और पर्यावरणीय आवरण जैसे सुरक्षा उपाय मशीनरी के गतिमान भागों, गिरती वस्तुओं या कठोर पर्यावरणीय परिस्थितियों के संपर्क के कारण होने वाले दुर्घटनाग्रस्त क्षति को रोकने में सहायता करते हैं। उत्पादन वातावरण में तर्कसंगत रूप से पूर्वानुमेय खतरों के विरुद्ध पर्याप्त सुरक्षा प्रदान करते हुए इन सुरक्षा प्रणालियों को सेंसर के संचालन में हस्तक्षेप नहीं करना चाहिए।

संयोजन और संबंध प्रणाली

रैखिक विस्थापन सेंसर और निगरानी वाले उपकरण के बीच यांत्रिक संपर्क के लिए बल संचरण विशेषताओं, घर्षण गुणों और रखरखाव पहुंच को ध्यान में रखने की आवश्यकता होती है। रॉड एंड जॉइंट, क्लेविस असेंबली और लचीले कपलिंग विभिन्न माउंटिंग विन्यासों को समायोजित करते हैं, जबकि मापन की शुद्धता पर प्रभाव डालने या सेंसर की जल्दबाजी से विफलता का कारण बनने वाले साइड लोडिंग को कम से कम करते हैं।

स्थापना प्रक्रियाओं में सामान्य संचालन सीमाओं से आगे अप्रत्याशित गति के कारण होने वाले नुकसान को रोकने के लिए उचित प्रीलोड सेटिंग्स, ट्रैवल सीमाओं और ओवरट्रैवल सुरक्षा का ध्यान रखना चाहिए। यांत्रिक स्टॉप और सुरक्षा उपकरण उपकरण खराबी या ऑपरेटर त्रुटियों के खिलाफ अतिरिक्त सुरक्षा प्रदान करते हैं जिनके परिणामस्वरूप सेंसर विस्थापन अत्यधिक हो सकता है।

यांत्रिक कनेक्शन के लिए नियमित निरीक्षण और चिकनाई की आवश्यकताएं लगातार विश्वसनीय संचालन सुनिश्चित करती हैं और माप प्रदर्शन को प्रभावित करने से पहले संभावित घिसावट की समस्याओं की पहचान करने में मदद करती हैं। रखरखाव प्रक्रियाओं को दस्तावेजीकृत किया जाना चाहिए और सेंसर सेवा जीवन को अधिकतम करने के लिए मानक उत्पादन लाइन रखरखाव कार्यक्रमों में शामिल किया जाना चाहिए।

विद्युत स्थापना और वायरिंग

पावर सप्लाई और ग्राउंडिंग

विद्युत स्थापना वोल्टेज स्तर, धारा आवश्यकताओं और स्थिरता विशेषताओं सहित बिजली की आपूर्ति विनिर्देशों के सत्यापन के साथ शुरू होती है, जो सही सेंसर संचालन सुनिश्चित करते हैं। स्वच्छ, स्थिर बिजली के स्रोत मापन शोर को कम करते हैं और अनियमित व्यवहार को रोकते हैं जो उत्पादन लाइन नियंत्रण प्रणाली के प्रदर्शन को नुकसान पहुँचा सकते हैं।

अर्थिंग प्रणाली को विद्युत शोर को दबाने के लिए कम-इम्पीडेंस मार्ग प्रदान करने चाहिए, जबकि ऐसे अनुप्रयोगों में मापन त्रुटियों को पेश कर सकने वाले ग्राउंड लूप से बचना चाहिए। एकल-बिंदु अर्थिंग योजनाएं आमतौर पर रैखिक विस्थापन सेंसर स्थापना के लिए इष्टतम प्रदर्शन प्रदान करती हैं, विशेष रूप से जब कई सेंसर निकटता में संचालित होते हैं।

पावर वितरण योजना भविष्य के विस्तार की आवश्यकताओं पर विचार करती है और विद्युत दोष या बिजली आपूर्ति में अनियमितताओं से होने वाले नुकसान को रोकने के लिए उपयुक्त सर्किट सुरक्षा उपकरणों को शामिल करती है। महत्वपूर्ण मापन अनुप्रयोगों के लिए समर्पित बिजली आपूर्ति मोटर्स, ड्राइव और अन्य उच्च-शक्ति उपकरणों द्वारा उत्पन्न विद्युत शोर से सेंसर सर्किट को अलग करने में सहायता करती है।

सिग्नल केबल स्थापना

केबल विनिर्देशों, ढाल प्रभावशीलता और भौतिक सुरक्षा उपायों पर सावधानीपूर्वक ध्यान देने की आवश्यकता के कारण सिग्नल केबल का चयन और मार्ग समान्यतः मापन सटीकता और प्रणाली की विश्वसनीयता को प्रभावित करते हैं। उपयुक्त चालक गेज और ढाल विन्यास वाली उच्च-गुणवत्ता वाली केबल सिग्नल क्षरण और वैद्युत चुम्बकीय हस्तक्षेप की संवेदनशीलता को कम करती हैं।

केबल रूटिंग पथ उच्च-तापमान वाले क्षेत्रों, चलने वाली मशीनरी और शक्तिशाली विद्युत चुम्बकीय क्षेत्र स्रोतों से बचते हुए भविष्य में रखरखाव और समस्या निवारण गतिविधियों के लिए पहुँच को बनाए रखना चाहिए। उचित केबल समर्थन प्रणाली तनाव संकेंद्रण और मोड़ने के कारण होने वाले क्षति को रोकती है जिससे अस्थायी कनेक्शन या पूर्ण सर्किट विफलता हो सकती है।

कनेक्शन समापन प्रक्रियाओं को विद्युत कनेक्शनों के विश्वसनीय दीर्घकालिक प्रदर्शन सुनिश्चित करने के लिए सटीक कार्यशैली और उपयुक्त उपकरणों की आवश्यकता होती है। उचित कनेक्टर असेंबली तकनीक, स्ट्रेन रिलीफ स्थापना और पर्यावरणीय सीलिंग नमी के प्रवेश और संक्षारण को रोकने में मदद करती है जो संकेत गुणवत्ता में कमी या सिस्टम विफलता का कारण बन सकती है।

कैलिब्रेशन और सिस्टम परीक्षण

प्रारंभिक कैलिब्रेशन प्रक्रियाएँ

कैलिब्रेशन प्रक्रियाएँ भौतिक विस्थापन और विद्युत आउटपुट संकेतों के बीच संबंध स्थापित करती हैं, जिससे निर्दिष्ट संचालन सीमा के भीतर अनुप्रयोग आवश्यकताओं के अनुसार मापन की शुद्धता सुनिश्चित होती है। संदर्भ मानक और परिशुद्ध मापन उपकरण राष्ट्रीय मानकों के साथ ट्रेसएबिलिटी प्रदान करते हैं तथा सेंसर के प्रदर्शन विशेषताओं को सत्यापित करते हैं।

बहु-बिंदु कैलिब्रेशन प्रक्रियाओं में आमतौर पर सेंसर को ज्ञात विस्थापन मानों पर स्थापित करना और रेखीयता विशेषताओं को स्थापित करने तथा किसी भी नियमित त्रुटि की पहचान करने के लिए संबंधित आउटपुट संकेतों को रिकॉर्ड करना शामिल होता है। कैलिब्रेशन डेटा के दस्तावेजीकरण से भविष्य के सत्यापन के लिए आधारभूत संदर्भ बनते हैं और समय के साथ धीरे-धीरे होने वाले प्रदर्शन परिवर्तनों की पहचान में सहायता मिलती है।

तापमान क्षतिपूर्ति सत्यापन अपेक्षित संचालन तापमान सीमा में सटीक माप सुनिश्चित करता है, जो उल्लेखनीय तापीय भिन्नता वाले अनुप्रयोगों के लिए विशेष रूप से महत्वपूर्ण है। विभिन्न तापमान स्थितियों के तहत सेंसर व्यवहार के चरित्रीकरण हेतु थर्मल परीक्षण में विशेष पर्यावरणीय कक्ष या विस्तारित निगरानी अवधि की आवश्यकता हो सकती है।

सिस्टम एकीकरण परीक्षण

व्यापक सिस्टम परीक्षण रैखिक विस्थापन सेंसर और उत्पादन लाइन नियंत्रण प्रणालियों, डेटा अधिग्रहण उपकरणों और मानव-मशीन इंटरफेस के बीच उचित एकीकरण को सत्यापित करता है। कार्यात्मक परीक्षण सामान्य संचालन स्थितियों के साथ-साथ दोष परिदृश्यों को शामिल करता है ताकि विभिन्न परिस्थितियों के तहत उचित प्रणाली प्रतिक्रिया सुनिश्चित की जा सके।

गतिशील प्रतिक्रिया परीक्षण सामान्य उत्पादन गतिविधियों के दौरान होने वाले आम गति, त्वरण प्रोफाइल और गतिमान पैटर्न सहित वास्तविक संचालन स्थितियों में सेंसर प्रदर्शन का मूल्यांकन करता है। इस परीक्षण से संभावित समस्याओं जैसे सिग्नल प्रोसेसिंग में देरी, फ़िल्टरिंग आवश्यकताएं या यांत्रिक अनुनाद जो मापन गुणवत्ता को प्रभावित कर सकते हैं, की पहचान करने में सहायता मिलती है।

संचार प्रोटोकॉल परीक्षण सेंसर और नियंत्रण प्रणालियों के बीच डेटा संचरण और प्राप्ति की सही व्यवस्था की पुष्टि करता है, जिसमें रखरखाव गतिविधियों का समर्थन करने वाली त्रुटि संभाल क्षमताएं और नैदानिक सुविधाएं शामिल हैं। नेटवर्क कनेक्टिविटी परीक्षण मौजूदा औद्योगिक संचार बुनियादी ढांचे के भीतर विश्वसनीय संचालन सुनिश्चित करता है।

मेंटेनेंस और ट्रUBLEशूटिंग

अग्रणी रखरखाव कार्यक्रम

नियमित निरीक्षण अनुसूचियों और प्रदर्शन सत्यापन प्रक्रियाओं के माध्यम से रैखिक विस्थापन सेंसर के सेवा जीवन को अधिकतम करने और निरंतर मापन सटीकता सुनिश्चित करने के लिए व्यवस्थित रखरखाव कार्यक्रम महत्वपूर्ण हैं। निवारक रखरखाव गतिविधियों में दृश्य निरीक्षण, विद्युत परीक्षण, यांत्रिक जांच और पूर्वनिर्धारित अंतराल पर की जाने वाली कैलिब्रेशन सत्यापन शामिल हैं।

पर्यावरणीय निगरानी सेंसर प्रदर्शन को प्रभावित कर सकने वाली बदलती परिस्थितियों—जैसे तापमान में बदलाव, आर्द्रता में परिवर्तन, कंपन में वृद्धि या संदूषण के जमाव—की पहचान करने में सहायता करती है। पर्यावरणीय परिवर्तनों का शुरुआती पता लगाने से मापन सटीकता में कमी या उपकरण विफलता से पहले सुधारात्मक उपाय लागू करने की अनुमति मिलती है।

रखरखाव गतिविधियों और प्रदर्शन रुझानों की प्रलेखन भविष्यवाणी रखरखाव रणनीतियों का समर्थन करता है और उपभोग्य घटकों के लिए उपयुक्त प्रतिस्थापन अंतराल की पहचान में सहायता करता है। रखरखाव रिकॉर्ड उपकरण समस्याओं के उद्भव होने पर समस्या निवारण गतिविधियों और वारंटी दावों के लिए भी मूल्यवान जानकारी प्रदान करते हैं।

सामान्य समस्याएं और समाधान

समस्या निवारण प्रक्रियाएँ सामान्य स्थापना और संचालन संबंधी समस्याओं को संबोधित करती हैं, जिनमें सिग्नल शोर, मापन विस्थापन, यांत्रिक घिसावट और विद्युत संपर्क समस्याएँ शामिल हैं। व्यवस्थित नैदानिक दृष्टिकोण जड़ कारणों की त्वरित पहचान करने और रखरखाव गतिविधियों के दौरान उत्पादन लाइन के बंद होने को न्यूनतम करने में सहायता करते हैं।

सिग्नल गुणवत्ता संबंधी समस्याएँ अक्सर विद्युत हस्तक्षेप, खराब ग्राउंडिंग प्रथाओं या अपर्याप्त केबल शील्डिंग के कारण होती हैं, जिन्हें सुधरी गई स्थापना तकनीकों या अतिरिक्त फ़िल्टरिंग उपायों के माध्यम से हल किया जा सकता है। मापन सटीकता संबंधी समस्याएँ मापन विचलन, यांत्रिक गलत संरेखण या सुधारात्मक कार्रवाई की आवश्यकता वाले पर्यावरणीय परिवर्तन का संकेत दे सकती हैं।

पर्यावरण संरक्षण का क्षरण नमी के प्रवेश, संदूषण के जमाव या तापमान से होने वाले नुकसान के कारण सेंसर की जल्दबाजी से विफलता का कारण बन सकता है। सुरक्षात्मक तत्वों का नियमित निरीक्षण और प्रतिस्थापन महंगी विफलताओं को रोकने और चुनौतीपूर्ण औद्योगिक वातावरण में विश्वसनीय संचालन बनाए रखने में मदद करता है।

सामान्य प्रश्न

रैखिक विस्थापन सेंसर के लिए माउंटिंग स्थान चुनते समय विचार करने के लिए सबसे महत्वपूर्ण कारक क्या हैं?

सबसे महत्वपूर्ण माउंटिंग विचारों में यांत्रिक स्थिरता, रखरखाव के लिए पहुंच, पर्यावरणीय खतरों से सुरक्षा और निगरानी वाले उपकरण के साथ संरेखण शामिल हैं। माउंटिंग स्थान को मापन त्रुटियों को रोकने के लिए कठोर समर्थन प्रदान करना चाहिए, साथ ही उचित सेंसर संरेखण और यात्रा सीमा की अनुमति देनी चाहिए। तापमान, कंपन और संदूषण के संपर्क जैसे पर्यावरणीय कारक सेंसर के आयु और प्रदर्शन सटीकता को महत्वपूर्ण रूप से प्रभावित करते हैं।

मेरे अनुप्रयोग के लिए उपयुक्त माप सीमा और रिज़ॉल्यूशन कैसे निर्धारित करें?

मापन सीमा के चयन में अधिकतम अपेक्षित विस्थापन के साथ-साथ अतिरिक्त यात्रा सुरक्षा के लिए सुरक्षा मार्जिन (आमतौर पर सामान्य संचालन सीमा से 10-20% अधिक) का विश्लेषण आवश्यक होता है। रिज़ॉल्यूशन आवश्यकताएँ उस सबसे छोटे स्थिति परिवर्तन पर निर्भर करती हैं जिसे विश्वसनीय रूप से पहचाना जाना आवश्यक होता है, जिसमें स्थापना वातावरण की यांत्रिक सटीकता की आवश्यकताओं और विद्युत शोर विशेषताओं दोनों पर विचार किया जाता है। उच्च रिज़ॉल्यूशन सेंसरों को अधिक परिष्कृत सिग्नल कंडीशनिंग और पर्यावरणीय सुरक्षा उपायों की आवश्यकता हो सकती है।

सामान्य बिजली आवश्यकताएँ और उपलब्ध सिग्नल आउटपुट विकल्प क्या हैं?

अधिकांश रैखिक विस्थापन सेंसर 12-24 VDC की मानक औद्योगिक बिजली आपूर्ति पर काम करते हैं, जिसमें धारा खपत आमतौर पर 100 मिलीएम्पीयर से कम होती है। सिग्नल आउटपुट विकल्पों में एनालॉग वोल्टेज या धारा सिग्नल, CANbus या ईथरनेट जैसे डिजिटल संचार प्रोटोकॉल और विशिष्ट नियंत्रण प्रणालियों के लिए विशेष इंटरफेस शामिल हैं। उच्च-रिज़ॉल्यूशन अनुप्रयोगों के लिए विशेष रूप से माप शुद्धता को सीधे प्रभावित करते हुए बिजली आपूर्ति की स्थिरता और शोर विशेषताएं होती हैं।

उत्पादन लाइन सेंसर के लिए कैलिब्रेशन सत्यापन कितनी बार किया जाना चाहिए?

मापन सत्यापन की आवृत्ति अनुप्रयोग की महत्वपूर्णता, पर्यावरणीय स्थितियों और नियामक आवश्यकताओं पर निर्भर करती है, जो अधिकांश औद्योगिक अनुप्रयोगों के लिए त्रैमासिक से लेकर वार्षिक तक की सीमा में होती है। गुणवत्ता नियंत्रण के महत्वपूर्ण अनुप्रयोगों को अधिक बार सत्यापन की आवश्यकता हो सकती है, जबकि स्थिर पर्यावरणीय स्थितियां लंबे अंतराल की अनुमति दे सकती हैं। विशिष्ट स्थापनाओं के वास्तविक प्रदर्शन विचलन गुणों के आधार पर इष्टतम सत्यापन अनुसूची निर्धारित करने में मापन डेटा की प्रवृत्ति निगरानी सहायता करती है।

विषय सूची

- रैखिक विस्थापन सेंसर तकनीक की समझ

- पूर्व-स्थापना योजना और मूल्यांकन

- यांत्रिक स्थापना प्रक्रियाएं

- विद्युत स्थापना और वायरिंग

- कैलिब्रेशन और सिस्टम परीक्षण

- मेंटेनेंस और ट्रUBLEशूटिंग

-

सामान्य प्रश्न

- रैखिक विस्थापन सेंसर के लिए माउंटिंग स्थान चुनते समय विचार करने के लिए सबसे महत्वपूर्ण कारक क्या हैं?

- मेरे अनुप्रयोग के लिए उपयुक्त माप सीमा और रिज़ॉल्यूशन कैसे निर्धारित करें?

- सामान्य बिजली आवश्यकताएँ और उपलब्ध सिग्नल आउटपुट विकल्प क्या हैं?

- उत्पादन लाइन सेंसर के लिए कैलिब्रेशन सत्यापन कितनी बार किया जाना चाहिए?