Förstå trycksensors prestanda vid extrema värmeförhållanden

Den industriella världen driver ständigt gränserna för vad som är möjligt med sensorteknik, särskilt när det gäller att mäta tryck i högtemperatur-miljöer. Modern trycksensorer ställs inför allt mer krävande utmaningar i applikationer som sträcker sig från övervakning av fordonsmotorer till industriella processanläggningar där temperaturerna kan stiga till extrema nivåer. Att förstå hur dessa sofistikerade instrument fungerar vid intensiv värme är avgörande för ingenjörer och industriella fackpersoner som söker tillförlitliga mätlösningar.

Motståndskraft mot temperaturer har blivit en avgörande egenskap vid val av trycksensorer, eftersom många industriella processer kräver exakta tryckmätningar i miljöer där temperaturerna kan överstiga flera hundra grader Celsius. Förmågan hos trycksensorer att bibehålla precision och tillförlitlighet under sådana förhållanden representerar en betydande teknologisk prestation och fortsätter att utvecklas i takt med innovationer inom materialvetenskap och ingenjörskonst.

Kärn tekniker som möjliggör drift vid höga temperaturer

Avancerade materialkompositioner

Grunden för drift av trycksensorer vid höga temperaturer ligger i noggrann materialval. Kiselbaserade sensorer, även om vanliga i standardapplikationer, ersätts av mer robusta alternativ i högtemperaturapplikationer. Specialiserade material som siliciumkarbid (SiC) och galliumnitrid (GaN) har visat sig vara ledande val för extrema temperaturapplikationer, tack vare sin överlägsna termiska stabilitet och mekaniska styrka.

Dessa avancerade material behåller sina sensoregenskaper även när de utsätts för temperaturer över 600°C, vilket gör dem idealiska för krävande industriella processer. Kristallstrukturen hos dessa föreningar motstår termisk deformation och säkerställer konsekventa tryckmätningar trots betydande temperatursvängningar.

Specialiserade konstruktionstekniker

Den interna arkitekturen i trycksensorer för höga temperaturer innehåller sofistikerade designelement för att hantera termisk stress. Tillverkare använder konstruktionsmetoder med flera lager, som utnyttjar termiska barriärer och specialiserade fästmetoder som tillåter termisk expansion samtidigt som strukturell integritet bevaras. Dessa konstruktionsmetoder innefattar ofta inbyggda temperaturkompenseringsmekanismer direkt i sensorns montering.

Avancerade förpackningslösningar skyddar känsliga elektroniska komponenter samtidigt som sensorelementet kan förbli i direkt kontakt med det medium som mäts. Denna noga balans mellan skydd och exponering möjliggör exakta tryckmätningar utan att sensorns livslängd försämras under extrema förhållanden.

Prestandaöverväganden i högtemperaturapplikationer

Noggrannhet Och Kalibreringskrav

Att använda trycksensorer vid höga temperaturer medför unika utmaningar för mätprecision. Temperaturinducerade fel måste noggrant kompenseras genom både hårdvarudesign och mjukvarualgoritmer. Moderna högtemperaturtrycksensorer innehåller sofistikerade kalibreringstekniker som tar hänsyn till termiska effekter över hela driftområdet.

Flerpunkts kalibreringsförfaranden säkerställer noggrannhet vid olika temperaturpunkter, med vissa avancerade sensorer som har dynamisk kompensation som kontinuerligt justerar för temperaturvariationer. Denna metod upprätthåller mätprecision även vid snabba temperaturförändringar, vilket är avgörande för processer som kräver övervakning och kontroll i realtid.

Långt liv och tillförlitlighet

Trycksensorernas hållbarhet i högtemperatur-miljöer beror i hög grad på deras konstruktionskvalitet och implementering av skyddande åtgärder. Regelbunden exponering för extrema temperaturer kan påskynda komponenternas åldrande, vilket potentiellt påverkar långsiktig mätstabilitet. Moderna konstruktionsmetoder innefattar dock funktioner som betydligt förlänger sensorns livslängd.

Skyddande belägg, tekniker för termisk isolering och robusta elektriska kopplingar bidrar alla till förbättrad tillförlitlighet. Många trycksensorer för höga temperaturer erbjuder idag imponerande medelvärdetid mellan fel (MTBF), även vid kontinuerlig drift i höga temperaturer.

Applikationsspecifika implementeringar

Industriell processövervakning

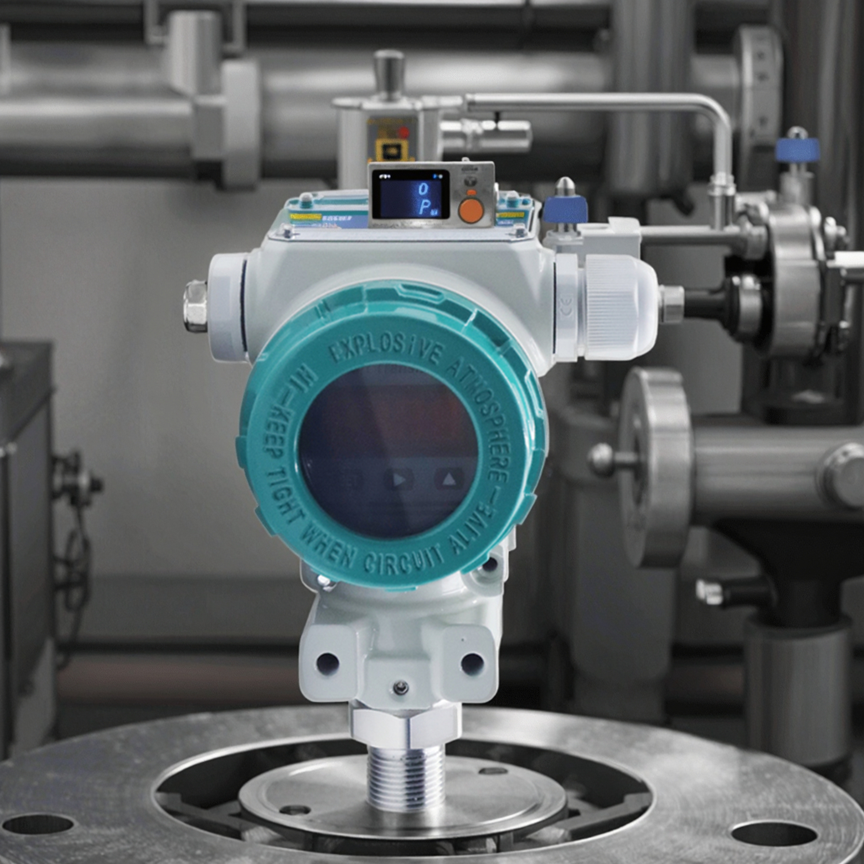

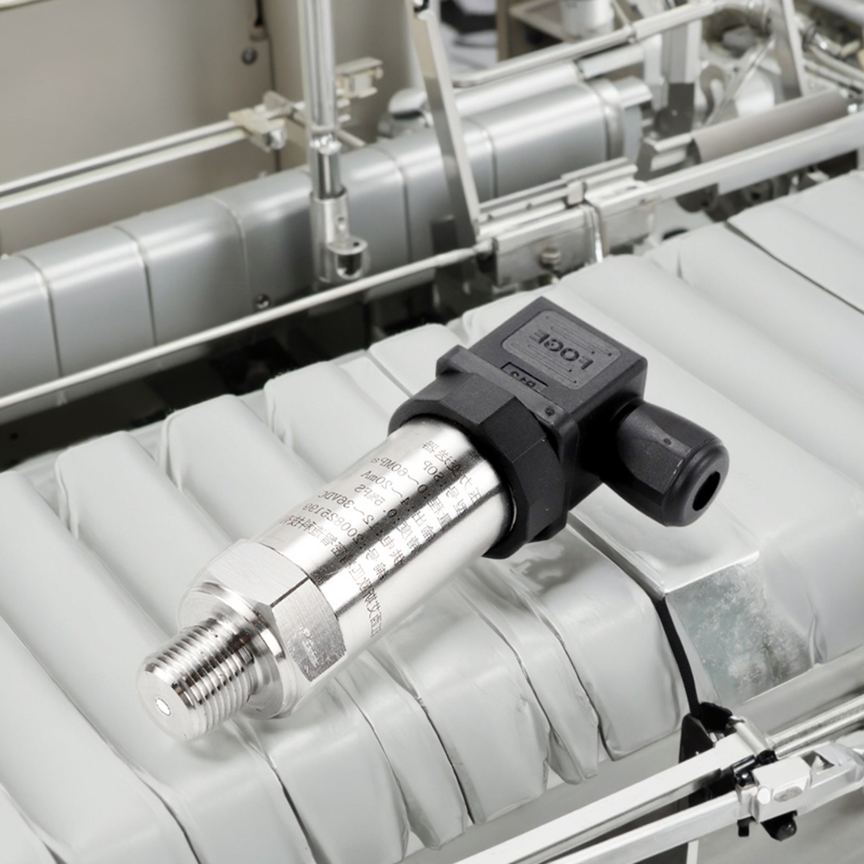

I industriella miljöer spelar trycksensorer för höga temperaturer en avgörande roll för att övervaka och styra olika processer. Kemiska reaktorer, ångsystem och system för hantering av högtemperaturvätskor är alla beroende av exakta tryckmätningar under extrema förhållanden. Dessa applikationer kräver ofta sensorer som inte bara klarar höga temperaturer utan också korrosiva miljöer.

Inkopplingen av dessa sensorer i industriella styrsystem kräver noggrann övervägning av installationspunkter, krav på termisk isolering och lämplig signalbehandling för att säkerställa tillförlitlig dataöverföring trots hårda miljöförhållanden.

Fordons- och flygplansapplikationer

Bil- och flygindustrin ställer unika krav på trycksensorers användning, särskilt i motorövervakning och avgassystem. Dessa miljöer kombinerar höga temperaturer med kraftiga vibrationer och snabba temperaturförändringar. Specialdesignade sensorkonstruktioner innefattar robusta monteringslösningar och förbättrad vibrationsresistens samtidigt som de behåller exakt tryckmätningsförmåga.

Modern flygmotorer och högpresterande fordonsystem är beroende av dessa sensorer för kritisk säkerhets- och prestandaövervakning, vilket gör pålitlighet under extrema förhållanden absolut nödvändigt.

Framtida utveckling och innovationer

Nya material och tekniker

Forskning fortsätter med att utveckla nya material och sensorteknologier som kan fungera vid ännu högre temperaturer. Nya keramiska föreningar och avancerade halvledarmaterial visar lovande resultat för att utöka trycksensorernas temperaturomfång bortom dagens begränsningar. Dessa framsteg kan möjliggöra tryckmätning i tidigare otillgängliga applikationer.

Integrering av artificiell intelligens och avancerade processningsmöjligheter direkt inom sensormoduler är en annan framväxande trend, som potentiellt kan erbjuda förbättrad temperaturkompensation och prediktivt underhåll.

Branschtrender och marknadsutveckling

Efterfrågan på trycksensorer för höga temperaturer fortsätter att öka när branscher utmanar driftgränserna. Tillverkare svarar med allt mer sofistikerade lösningar som kombinerar förbättrad temperaturmotståndskraft med förbättrad funktionalitet. Miniatyriseringstrender driver utvecklingen av kompakta sensorer som behåller förmågan att hantera höga temperaturer samtidigt som installationsutrymmet minskar.

Marknadsutvecklingen leder även till en ökad fokus på kostnadseffektiva lösningar som inte komprometterar prestanda, vilket gör avancerad teknik för tryckmätning vid höga temperaturer mer tillgänglig för ett brett utbud av tillämpningar.

Vanliga frågor

Vilken är den maximala temperatur en trycksensor normalt sett kan hantera?

Moderna trycktransmitter för höga temperaturer kan fungera tillförlitligt vid temperaturer mellan 150°C och 800°C, beroende på deras specifika design och konstruktion. Vissa specialgjorda sensorer kan till och med fungera vid temperaturer över 1000°C, även om dessa vanligtvis är anpassade lösningar för specifika applikationer.

Hur påverkar temperaturen trycktransmitterns noggrannhet?

Temperatur kan påverka trycktransmitterns noggrannhet genom termisk expansion av komponenter, förändringar i materialens egenskaper och elektronisk driftdrift. Moderna sensorer är dock utrustade med sofistikerade kompensationsmekanismer och specialmaterial för att upprätthålla noggrannhet över det angivna temperaturområdet.

Vilken underhållsintervall krävs för trycktransmitter för höga temperaturer?

Trycksensorer för hög temperatur kräver regelbundna kalibreringskontroller, kontroll av monteringsförhållanden och verifiering av signalements noggrannhet. Den specifika underhållsplanen beror på applikationens allvarlighet och driftsförhållanden, men de flesta moderna sensorer är utformade för minimala underhållskrav så länge de används inom den specificerade temperaturintervallet.