Ever wondered how engineers recreate the feel of driving a car without leaving the lab? The answer lies in clever engineering—specifically, the use of linear displacement transducers to simulate real-world driving conditions. These devices measure physical movement with precision, making them invaluable for testing vehicle dynamics, suspension behavior, and even driver feedback systems. Here’s how they’re transforming automotive development.

1. Capturing Real-World Motion: The Core Role of Linear Displacement Transducer

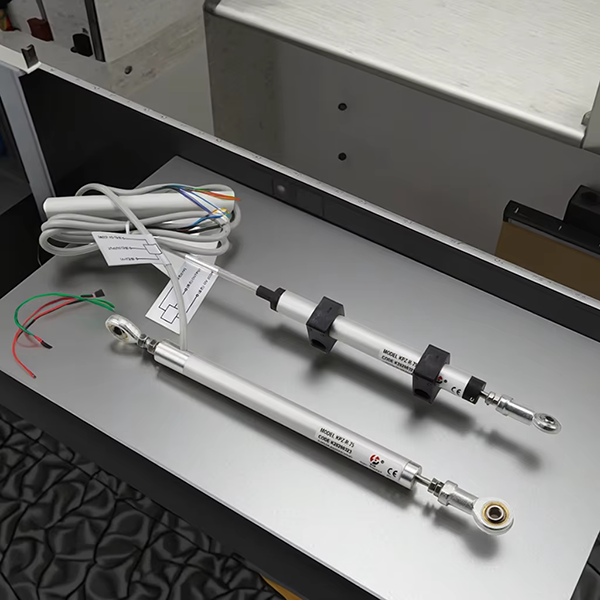

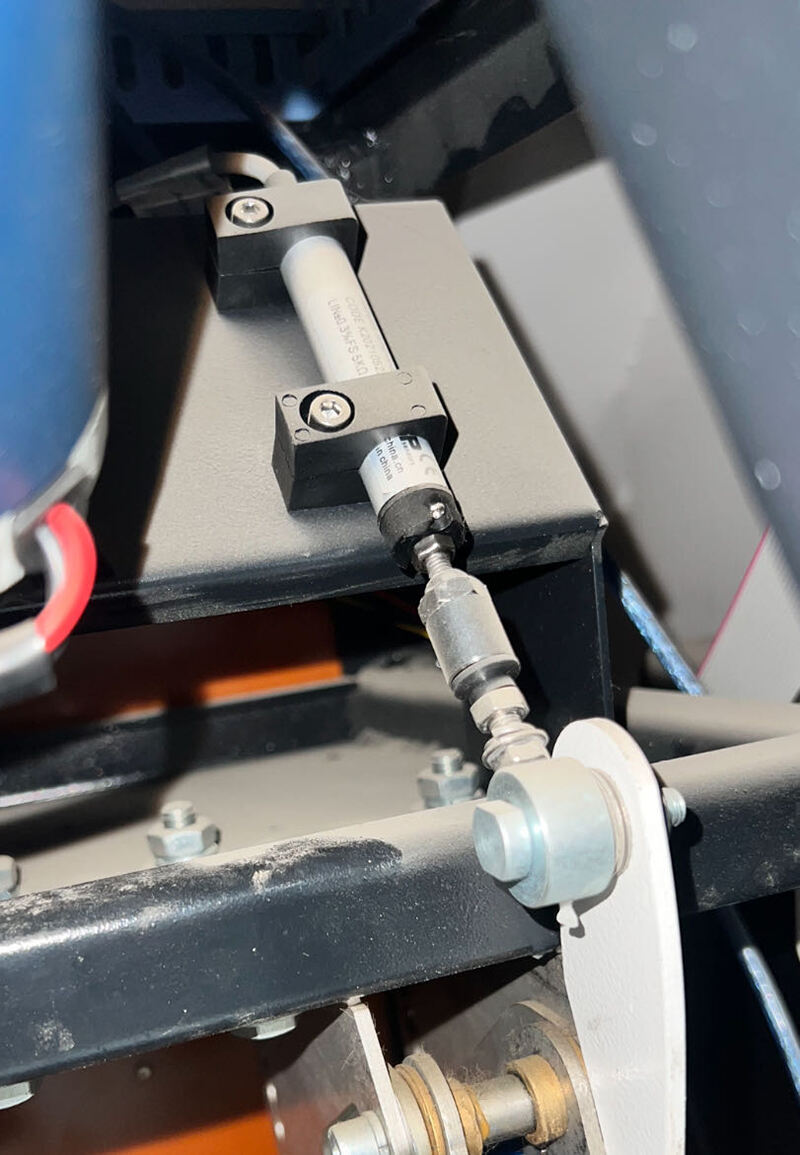

Linear displacement transducers are sensors that convert mechanical movement into electrical signals. In driving simulations, they’re often attached to key components like suspension arms, steering columns, or brake pedals to track displacement in real time. For example, when a vehicle hits a bump, an Linear Displacement Transducer can measure how much the suspension compresses and rebounds, providing data to engineers on how the system absorbs shocks. This helps refine designs for comfort and safety without needing actual road testing.

2. Enhancing Test Rig Accuracy: From Static to Dynamic

Traditional vehicle testing often occurs in static environments, which limits insights into how systems behave under motion. Linear displacement transducers bridge this gap by enabling "drivable" test rigs—where engineers can "drive" a vehicle setup while sensors record every movement. For instance, a test rig might simulate cornering forces by displacing wheels via actuators, while Linear displacement transducers measure the resulting body roll. This approach saves time and costs by replicating dynamic conditions in a controlled lab.

3. Supporting Advanced Vehicle Technologies

As cars evolve with electrification and autonomy, linear displacement transducers adapt to new challenges. In electric vehicles, they monitor battery pack expansion under thermal stress, while in autonomous systems, they ensure precise actuator responses for steering or braking. By integrating linear displacement transducer data with computational models, engineers can predict how vehicles will perform in diverse scenarios, from high-speed maneuvers to low-speed urban driving.

4. Future Directions: Integration with AI and Simulation

The next frontier involves merging linear displacement transducer data with AI-driven simulation tools. Imagine a system where real-time displacement feeds into virtual environments, allowing engineers to test thousands of driving scenarios instantly. This could accelerate development for self-driving cars, where every millimeter of movement matters for safety algorithms.

Why It Matters

Linear displacement transducers are unsung heroes in automotive innovation. By translating physical motion into actionable data, they help create vehicles that are safer, more efficient, and closer to the driving experience we love. Whether you’re a engineer or a car enthusiast, these devices are quietly shaping the future of mobility.

If you have any need for linear displacement transducer, please send us a inquiry!