Today, I’d like to share some insights into how linear displacement sensors play a crucial role in automatic screw locking machines. These machines are widely used in manufacturing to improve efficiency and precision. Let’s break it down step by step.

Understanding the Basics

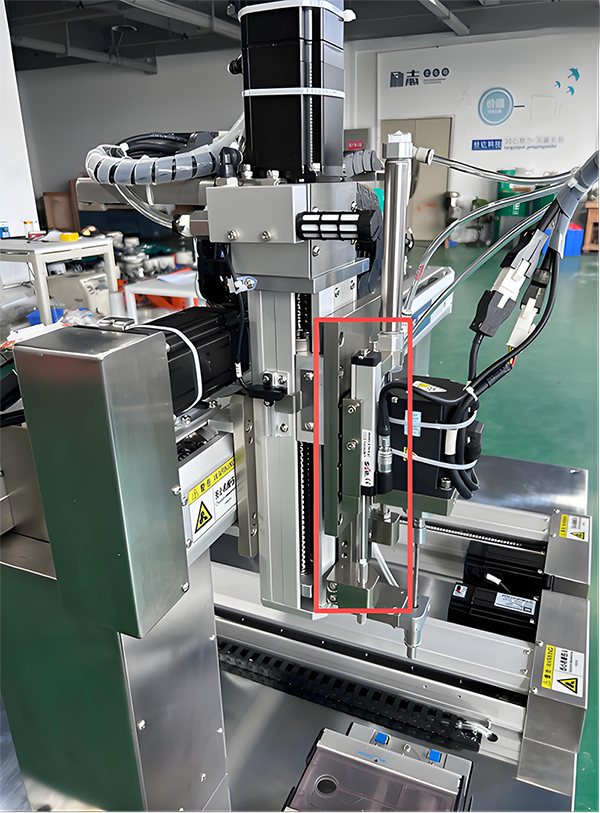

An automatic screw locking machine is designed to replace manual labor in screwing processes. It typically consists of a feeding system, a screwdriver, and a control unit. The machine picks up screws from a feeder, positions them accurately, and then drives them into the workpiece. This process requires high precision to ensure screws are inserted correctly without damaging the threads or the material.

Role of Linear Displacement Sensors

Linear displacement sensors are key components that enhance the accuracy and reliability of these machines. Here’s how they contribute:

Precision Positioning: The sensor measures the exact position of the screwdriver tip relative to the workpiece. This ensures that each screw is driven into the correct location with minimal deviation. For example, if the screwdriver moves too far or not enough, the sensor detects this and adjusts the position in real-time.

Quality Control: By monitoring the displacement during the screwing process, the sensor can detect issues like missed screws or incorrect depths. It can trigger alerts or stop the machine if a screw is not properly seated, preventing defective products from moving down the assembly line.

Adaptability: Different workpieces may require varying screw depths. The sensor allows the machine to adapt to these changes by adjusting the screwdriver’s movement based on real-time feedback. This flexibility is crucial for handling diverse manufacturing tasks.

Real-World Applications

In industries like electronics or automotive manufacturing, where tiny screws are used in delicate components, the precision provided by these sensors is invaluable. For instance, in assembling smartphone parts, even a slight misalignment can render the device useless. The sensor ensures that every screw is placed perfectly, enhancing product reliability.

Challenges and Solutions

While linear displacement sensors offer significant advantages, they are not without challenges. Environmental factors like dust or vibrations can affect sensor accuracy. However, modern sensors are designed with robust materials and protective features to withstand harsh conditions. Regular calibration and maintenance also help maintain optimal performance.

Future Prospects

As technology advances, we can expect these sensors to become even more integrated into automatic screw locking machines. Innovations like wireless connectivity and AI-driven analytics may further improve efficiency and reduce downtime. Imagine a machine that predicts maintenance needs before failures occur—this is where the industry is heading.

Linear displacement sensors are unsung heroes in the world of automatic screw locking machines. They ensure precision, enhance quality, and enable adaptability, making them indispensable in modern manufacturing. Whether you’re in electronics, automotive, or any other industry that relies on screwing processes, understanding these sensors can help you optimize your operations.