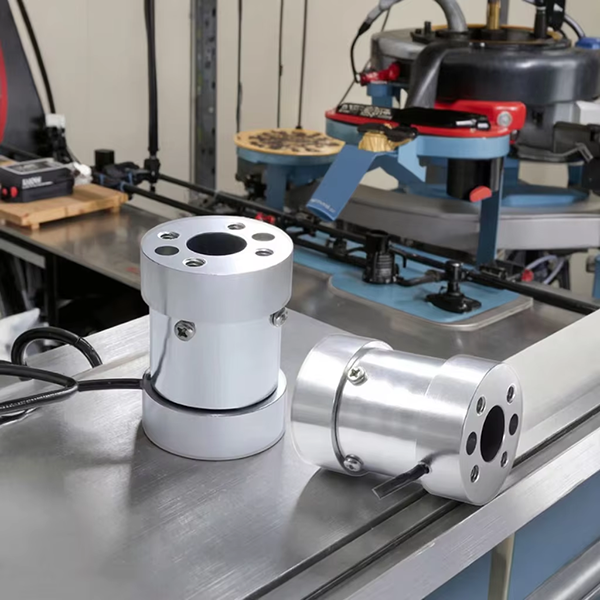

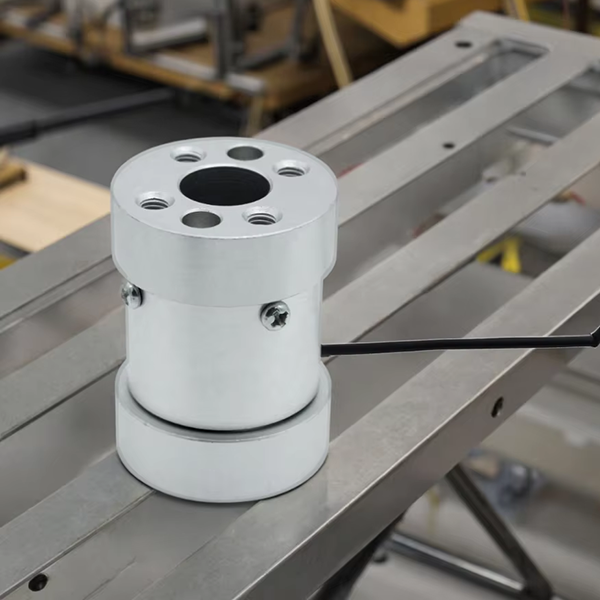

In modern manufacturing, automatic screw locking machines have become indispensable for assembling everything from smartphones to automotive engines. At the heart of these machines lies a unsung hero: the torque sensor. This tiny but powerful device plays a crucial role in ensuring screws are tightened with just the right amount of force, preventing everything from loose connections to damaged threads. Let me share how torque sensors work their magic in these machines.

1. Precision Control During Tightening

The primary job of a torque sensor in an automatic screw locking machine is to measure the rotational force applied to the screw in real-time. Unlike manual tightening where operators rely on feel, these sensors provide exact data on how much torque is being exerted. For example, when assembling delicate electronics, the sensor ensures screws are tightened to a specific torque range—neither too loose nor too tight—thereby preventing component damage or failure. This precision is particularly vital in industries like aerospace, where even minor deviations can lead to catastrophic consequences.

2. Preventing Over-Torqueing

One of the biggest risks in screw tightening is over-torqueing, which can strip threads or deform materials. Torque sensors act as a safeguard by continuously monitoring the force. If the torque exceeds a preset threshold, the machine instantly stops or alerts operators. This feature is especially useful in automated production lines where hundreds or thousands of screws are tightened daily. By preventing over-torqueing, sensors extend the lifespan of fasteners and reduce costly rework or scrap.

3. Enhancing Quality Assurance

In quality-critical applications, such as medical devices or automotive safety components, consistent torque is non-negotiable. Torque sensors enable automated machines to verify that each screw meets exact specifications. Some advanced systems even integrate with data logging software, allowing manufacturers to track and audit tightening processes for compliance. This traceability ensures that every product leaving the assembly line meets stringent quality standards, boosting customer confidence and reducing warranty claims.

4. Adapting to Different Materials

Different materials—whether plastic, metal, or composite—require varying torque levels to avoid cracking or deformation. Torque sensors help automatic screw locking machines adapt on the fly. For instance, when assembling a smartphone, the sensor might apply lower torque to plastic housing than to metal screws in the internal frame. This adaptability makes the machines versatile for diverse manufacturing needs, eliminating the need for manual adjustments between jobs.

5. Improving Efficiency and Reducing Downtime

By eliminating guesswork, torque sensors streamline production. They enable machines to work at optimal speeds without compromising accuracy, significantly reducing cycle times. Moreover, by preventing screw-related failures, they minimize machine downtime caused by jams or broken components. In high-volume environments, this efficiency translates into substantial cost savings and faster time-to-market for products.

6. Integration with Smart Systems

Modern torque sensors often connect to IoT networks, enabling predictive maintenance. By analyzing torque data trends, manufacturers can detect wear in machine components before failures occur. For example, a gradual increase in torque readings might indicate a dull screwdriver bit, prompting timely replacement before it causes defects. This proactive approach keeps production lines running smoothly and reduces unexpected stoppages.

Torque sensors are the silent guardians of automatic screw locking machines, ensuring screws are tightened with precision, consistency, and reliability. From preventing over-torqueing to enabling smart manufacturing, they play a pivotal role in enhancing product quality and operational efficiency. As industries push towards automation and higher standards, the humble torque sensor will continue to be a cornerstone of modern assembly processes, bridging the gap between mechanical force and digital control.