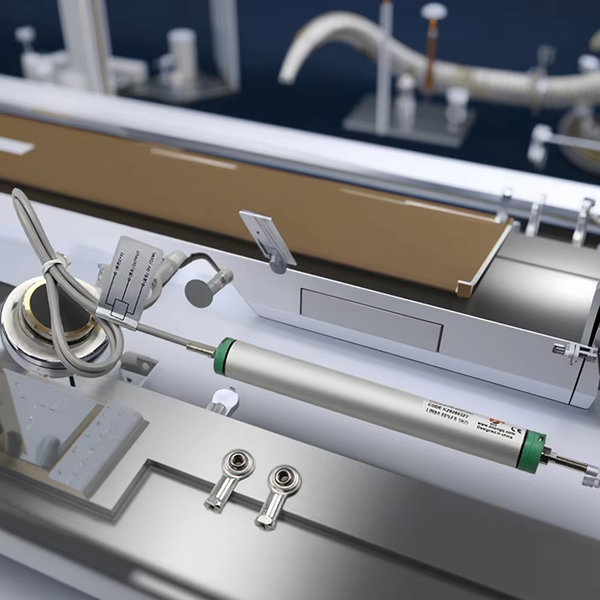

In industrial machinery, automotive systems, and precision equipment, linear position sensors quietly work behind the scenes to ensure smooth operation and safety. These devices play a crucial role in translating physical movement into measurable data, enabling precise control and feedback in countless applications. Let's explore their core purpose and how they impact modern technology.

1. Translating Movement into Data

At its essence, a linear position sensor detects the position or displacement of an object along a straight path. Unlike switches that simply indicate "on" or "off," these sensors provide continuous analog or digital feedback, offering fine-grained insights into an object's location. For example, in hydraulic cylinders or robotic arms, they monitor the exact extension or retraction of components, ensuring movements are executed with millimeter-level accuracy. This capability is vital in manufacturing, where even minor deviations can lead to defects or inefficiencies.

2. Enhancing Safety and Efficiency

By eliminating the need for physical contact between the sensor and the target, modern linear position sensors reduce wear and tear, significantly extending their lifespan. Non-contact designs, often based on magnetic or inductive principles, are immune to mechanical failures caused by friction or environmental contaminants. In automotive applications, such as steering systems or throttle control, they enhance reliability by providing real-time data to electronic control units (ECUs), enabling adaptive responses to driver inputs or road conditions.

3. Enabling Precision in Diverse Applications

The versatility of linear position sensors spans industries:

Industrial Automation: In CNC machines or material handling equipment, they ensure precise tool positioning, optimizing production quality.

Aerospace: Aircraft actuators rely on these sensors to maintain stability during flight by continuously adjusting control surfaces.

Consumer Electronics: Even in everyday devices like printers or sliding doors, they enable smooth and responsive movement.

4. Supporting Smart Systems

As technology advances, these sensors integrate with IoT networks and AI-driven platforms. For instance, in predictive maintenance systems, they detect subtle changes in equipment behavior, alerting operators to potential issues before failures occur. This proactive approach minimizes downtime and reduces operational costs.

The main purpose of a linear position sensor goes beyond mere measurement—it transforms physical motion into actionable intelligence, fostering efficiency, safety, and innovation. Whether in a factory, car, or aircraft, these unassuming devices are silent enablers of progress, bridging the gap between mechanical movement and digital control. As industries evolve, their importance will only grow, reinforcing their status as indispensable components in the modern technological landscape.