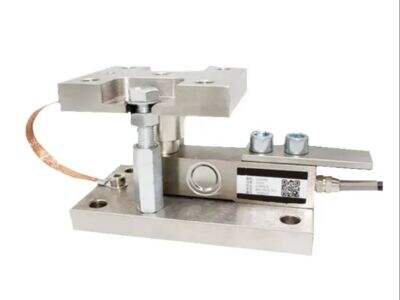

analog load cell

An analog load cell is a precision measurement device that converts mechanical force into electrical signals through strain gauge technology. This fundamental component in weighing systems operates by detecting physical deformation when force is applied, transforming this mechanical stress into proportional electrical outputs. The device consists of strain gauges bonded to a metal element, typically constructed from high-grade steel or aluminum, which deforms elastically under applied force. When weight or force is applied, the metal element flexes slightly, causing the strain gauges to experience dimensional changes. These changes alter the electrical resistance of the gauges, producing a voltage output that directly correlates to the applied force. Analog load cells find extensive applications across various industries, from industrial manufacturing and process control to agricultural weighing and laboratory measurements. They are particularly valued in scenarios requiring continuous force monitoring, such as in conveyor belt systems, tank weighing, and material testing equipment. The analog output signal they provide is especially useful for real-time monitoring and control applications, offering immediate response to weight changes and enabling precise process control.