Modern Sanayide Yük Hücresi Teknolojisini Anlamak

Yük hücrelerine mekanik kuvveti elektriksel sinyallere dönüştüren, çeşitli endüstrilerde kritik rol oynayan ölçüm cihazlarıdır. İmalat ve havacılık sanayisinden tıbbi ekipmanlara ve perakende terazilere kadar bu hassas cihazlar, sayısız uygulamada doğru kuvvet ölçümlerini sağlar. Teknoloji ilerledikçe, farklı endüstriyel ihtiyaçlara ve ölçüm gereksinimlerine hitap etmek üzere çeşitli yük hücreleri geliştirilmiştir.

Tasarıma Göre Yaygın Yük Hücresi Kategorileri

Şekil Değiştirme Ölçer Yük Hücreleri

Şekil değiştirme ölçerli yük hücreleri, endüstriyel uygulamalarda en yaygın kullanılan kategori olarak öne çıkar. Bu cihazlar, uygulanan kuvvet altında şekil değiştiren bir metal elemana yapıştırılmış şekil değiştirme ölçerlerden yararlanır. Ağırlık veya kuvvet uygulandığında metal hafifçe bükülür ve şekil değiştirme ölçerlerin elektriksel direncini orantılı olarak değiştirir. Dirençteki bu değişim daha sonra ölçülebilir bir elektrik sinyaline dönüştürülür.

Modern şekil değiştirme ölçerli yük hücreleri, yüksek doğruluk, güvenilirlik ve maliyet etkinliği sunar. Bu hücreler, geniş bir sıcaklık aralığında istikrarlı performans gösterir ve birkaç gramdan birkaç yüz tona kadar kapasiteleri destekler. Esneklikleri ile öne çıkan bu hücreler, platform terazileri, kamyon tartım sistemleri ve süreç kontrol uygulamaları için idealdir.

Hidrolik Yük Hücresi

Hidrolik yük hücreleri, kuvveti ölçmek için sıvı basıncını kullanan farklı bir prensibe göre çalışır. Bu cihazlar, yağ veya başka bir hidrolik sıvı ile doldurulmuş bir kamaradan oluşur. Kuvvet uygulandığında kamaradaki basınç artar ve bu basınç, bir basınç göstergesi veya basınç transdüseri tarafından ölçülür. Basınç ölçümü, doğrudan uygulanan kuvvetle ilişkilidir.

Bu tür yük hücreleri, elektrikli sistemlerin zarar görebileceği sert ortamlarda üstün performans gösterir. Patlayıcı atmosferlerde veya yüksek elektromanyetik girişimin bulunduğu yerlerde özellikle değerlidirler. Sağlam yapıları sayesinde ağır sanayi uygulamaları ve açık alanda kurulumlar için uygundurlar.

Özel Yük Hücresi Konfigürasyonları

Tek Nokta Yük Hücreleri

Tek noktalı yük hücreleri, yükün konumu ne olursa olsun doğruluk gerektiren uygulamalar için özel olarak üretilmiştir. Bu yük hücreleri, merkeze off yüklemeyi telafi eder ve bu nedenle perakende terazileri ve küçük platform tartım sistemleri için idealdir. Kompakt tasarımı ve montaj gereksinimlerini basitleştirilmesi, kurulumun ve bakımın daha kolay yapılmasını sağlar.

Modern tek noktalı tasarımlar sıcaklık kompanzasyonu ve aşırı yük koruma özellikleri içermektedir. Genellikle 0,5 kg ila 1000 kg arası kapasitelerde çalışırlar ve eksantrik yükler altında bile mükemmel doğruluk sağlarlar. Bu çok yönlü özellik, onları gıda işleme ve perakende ortamlarında giderek daha popüler hale getirmiştir.

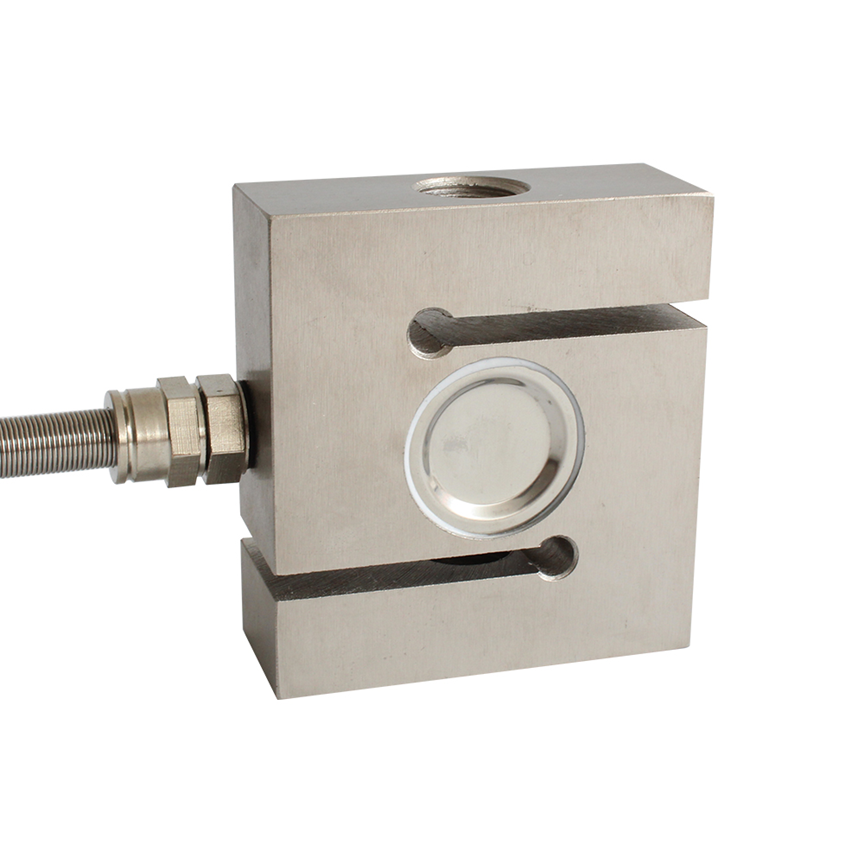

S-Tipi Yük Hücreleri

S-tipi yük hücreleri, benzersiz S şeklindeki tasarımıyla isimlendirilir ve hem çekme hem de basma ölçümünde üstün performans gösterir. Özel geometrileri, her iki yöndeki kuvvetleri eşit doğrulukta ölçmelerine olanak tanır. Bu çok yönlü cihazlar, vinç terazilerinde, malzeme testlerinde ve endüstriyel süreç kontrolünde yaygın olarak kullanılır.

S-tipi yapı, yüke maruz kaldığında üstün stabilite ve minimum sehim sağlar. Bu tasarım özelliği, hızlı tepki ve doğruluğun kritik olduğu dinamik tartım uygulamaları için onları özellikle uygun kılar. Hem çekme hem de basma ölçümü yapabilme özelliği, genellikle ayrı çekme ve basma sensörlerine olan ihtiyacı azaltır.

Gelişmiş Yük Hücresi Teknolojileri

Pnömatik Yük Hücreleri

Pnömatik yük hücreleri, kuvvet ölçümünde hava basıncını kullanır ve özel uygulamalarda benzersiz avantajlar sunar. Bu cihazlar, uygulanan kuvveti hapsolmuş bir hava hacmiyle dengeleyerek çalışır. Ağırlık arttıkça dengeyi korumak için gereken hava basıncı orantılı olarak değişir ve böylece hassas bir ölçüm elde edilir.

Bu tür yük hücreleri, temizliğin ve kontaminasyonun önlenmesinin en yüksek öncelik olduğu ortamlarda, örneğin ilaç üretimi ve gıda işleme sektörlerinde üstün performans gösterir. Basit mekanik tasarımı, düşük bakım gereksinimi sunar ve doğrudan patlama koruması sağlar.

Dijital yük hücresi

Dijital yük hücreleri, kuvvet ölçüm teknolojisindeki en son gelişmeyi temsil eder. Bu gelişmiş cihazlar, yük hücresi muhafazasının içinde doğrudan analog-sayısal dönüşüm özelliğini barındırır; bu da artırılmış hassasiyet ve modern kontrol sistemleriyle entegrasyonu kolaylaştırır. Genellikle kendini tanılayan sistemler ve otomatik sıcaklık kompanzasyonu gibi gelişmiş özellikler içerir.

Dijital çıkış, geleneksel ölçüm hatalarının çoğunu ortadan kaldırır ve elektromanyetik girişime karşı olan eğilimi azaltır. Bu avantajlar, dijital yük hücrelerini yüksek hassasiyet gerektiren uygulamalarda ve otomatik üretim ortamlarında giderek daha popüler hale getirir.

Çevresel Faktörler ve Seçim Kriterleri

Çevre koruma standartları

Farklı yük hücre tipleri, genellikle IP (Giriş Koruma) dereceleri ile belirtilen değişen çevre koruma seviyeleri sunar. Tamamen sızdırmaz mühürlenmiş yük hücreleri, nem ve toza karşı en yüksek korumayı sağlar ve bunlar yıkama ortamları ile dış mekan kurulumları için uygundur.

Uygun koruma seviyesinin seçilmesi, kimyasallara maruz kalma, sıcaklık değişimleri ve temizlik gereksinimleri gibi faktörlere bağlıdır. Bu çevresel etkenleri anlamak, uzun vadeli güvenilirliğin ve doğruluğun sağlanması açısından hayati öneme sahiptir.

Uygulama Özel Gereksinimleri

Doğru yük hücresi tipini seçmek, kapasite aralığı, doğruluk gereksinimleri, kurulum alanı kısıtlamaları ve bütçe sınırlamaları gibi uygulamaya özgü faktörlerin dikkatli bir şekilde değerlendirilmesini gerektirir. Çalışma ortamı, bakım kabiliyetleri ve mevcut sistemlerle entegrasyon gereksinimleri de seçim sürecinde önemli rol oynar.

Yük hücresi üreticileriyle veya deneyimli sistem entegratörleriyle yapılan profesyonel danışmanlık, belirli uygulamalar için optimal çözümün belirlenmesine yardımcı olabilir. Bu uzmanlık, yük hücresi özelliklerinin uygulama gereksinimleriyle doğru şekilde eşleştirilmesini sağlar.

Sıkça Sorulan Sorular

Yük hücresi doğruluğunu etkileyen faktörler nelerdir?

YÜK HÜCRESİ temperatür değişimleri, nem, elektromanyetik müdahale, mekanik hizalama ve kalibrasyon kalitesi de dahil olmak üzere birçok faktörden etkilenir. En iyi performansı korumak için düzenli bakım ve uygun kurulum şarttır.

Yük hücreleri genellikle ne kadar dayanır?

Uygun kurulum ve bakım ile kaliteli yük hücreleri 10-15 yıl veya daha uzun süre güvenilir şekilde çalışabilir. Ancak gerçek kullanım ömrü, çalışma koşullarına, yükleme döngülerine ve çevresel faktörlere bağlı olarak değişir. Düzenli kalibrasyon ve muayene, sürekli doğruluğun sağlanması için önemlidir.

Yük hücreleri hasar görürse onarılabilir mi?

Küçük sorunlar onarılabilir olmakla birlikte, çoğu yük hücresi doğruluğu riske etmeden etkili bir şekilde onarılamayacak şekilde kapalı ünitelerdir. Bir yük hücresi arızalandığında veya belirtilen özelliklerden önemli ölçüde sapma gösterdiğinde genellikle değiştirilmesi önerilir.

Yük hücrelerinin çalışması için ne tür bakım gerekir?

Düzenli bakım, hasar için görsel kontrol, montaj parçalarının kontrol edilmesi, ortama uygun temizlik yapılması ve periyodik kalibrasyon doğrulamalarını içerir. Bakım programı, uygulama alanına ve çalışma koşullarına bağlı olarak değişiklik gösterebilir.