Вы когда-нибудь задумывались, как инженеры измеряют расстояние, которое объект преодолел? Это довольно интересно! В инженерном деле сенсор перемещения LVDT является полезным инструментом для инженеров, когда им нужно определить, насколько далеко переместился объект. LVDT означает Линейный Дифференциальный Трансформатор, и это может показаться слишком высокотехнологичным, но давайте разберёмся.

Датчик LVDT — это тип сенсора, похожий на энкодер тем, что он сообщает нам о положении или движении объекта. Более конкретно, этот сенсор хорошо справляется с измерением того, насколько объект переместился. Перемещение относится к расстоянию, которое объект прошел от начальной точки. Например, представьте карандаш на вашем столе. Если вы проведете карандашом с одной стороны блокнота на другую, то он будет считаться перемещенным. Остается только вопрос: насколько далеко он переместился!

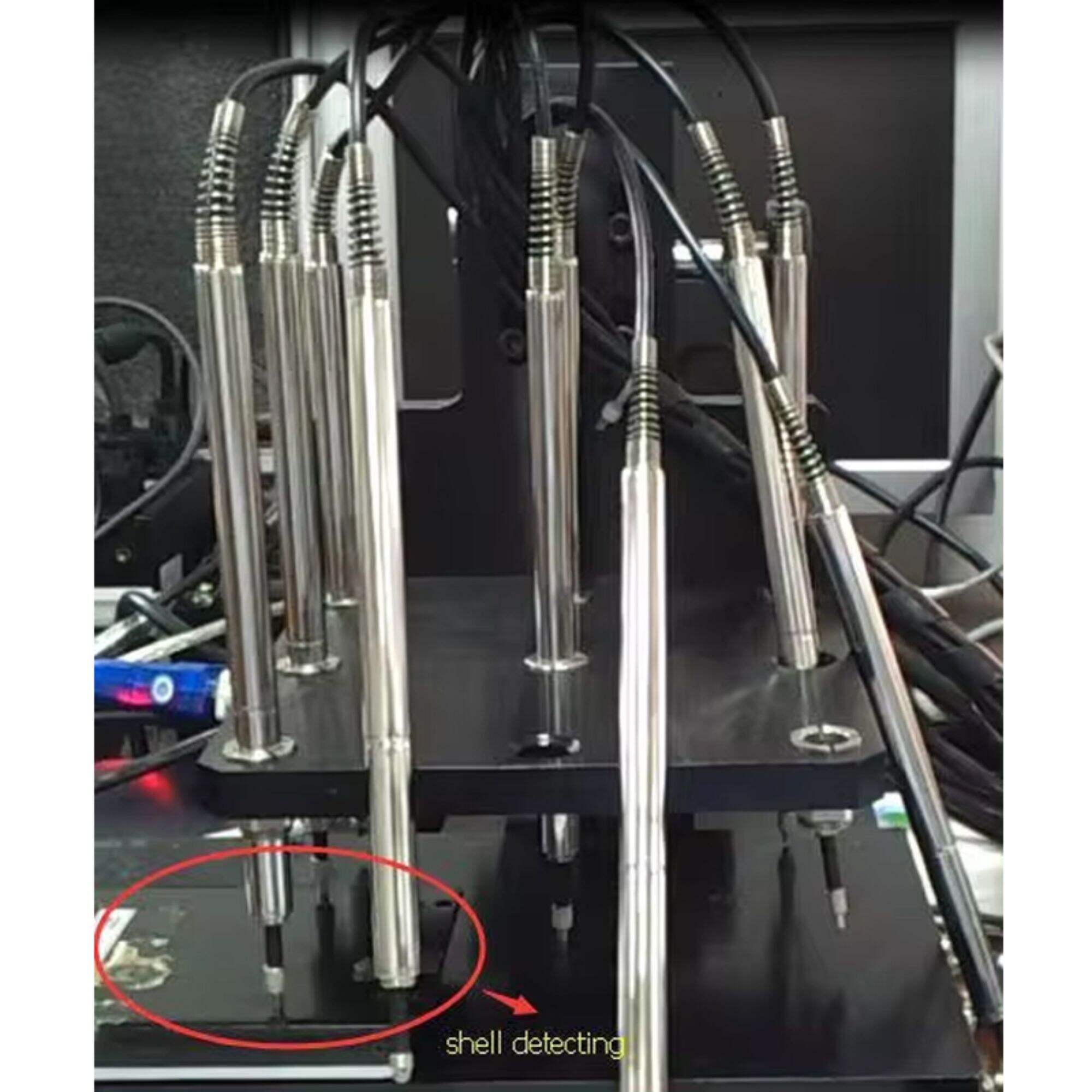

Основной принцип работы LVDT показан на рисунке. Одна из особенностей LVDT заключается в том, что он может использоваться для измерений без контакта с измеряемым объектом. Это означает, что он совершенно не повлияет на продукт. Он не зависит от физического контакта, а использует магнитное поле для определения положения объекта. При создании LVDT трубка наматывается проводом, и есть ещё один металлический элемент, который плотно помещается внутри самой трубки.

Электрическая мощность, проходящая через катушку провода, создаёт магнитное поле. Металлический элемент движется внутрь и наружу трубки; это изменяет магнитное поле. Такие изменения обнаруживаются устройством, называемым LVDT. Затем оно преобразует эти изменения магнитного поля в электрический сигнал. Этот электрический сигнал можно отобразить на экране компьютера и использовать в качестве входного устройства, а также в других местах инженерами или учёными.

Чувствительность ЛВДТ — это большое преимущество. Это означает, что он может обнаруживать даже самые маленькие различия в направлении, куда указывает объект. Работая по тому же принципу, это значит, что он может обнаруживать вещи, которые другие датчики могут пропустить из-за своей низкой чувствительности. Например, движущиеся части внутри машины, что может быть крайне важно для обеспечения правильной работы всего оборудования!

ЛВДТ выполняет свою функцию как очень универсальное устройство и может использоваться в различных условиях. Например, он может подтверждать правильное расположение элемента в автомобильном двигателе, или обеспечивать надежную фиксацию клапана на трубе — или даже проверять, не отсутствует ли крепёж на крыле самолёта. Вот лишь некоторые примеры того, насколько универсальными могут быть приложения ЛВДТ в различных отраслях.

Датчик LVDT также служит основной необходимостью для их экспериментов у учёных. В лаборатории учёные могут использовать датчик LVDT, чтобы измерить изменения формы какого-либо камня на протяжении нескольких лет или отследить, как жидкость течёт в контролируемой среде. Это также делает датчик LVDT важным инструментом в научных исследованиях.

Мы аккредитованы CE, RoHS и ISO9001. Мы обеспечиваем строгий контроль каждого продукта перед отправкой. Кроме того, SOP предоставляет профессиональную техническую поддержку после продажи датчика перемещения LVDT для проблем с продукцией, а также других вопросов.

SOP обладает более чем 20-летним опытом производства, сотрудничая более чем с 500 международными клиентами. Это профессиональное производственное высокотехнологичное предприятие, занимающееся исследованием, разработкой, производством датчиков перемещения LVDT и обслуживанием различных типов датчиков.

Мы предлагаем широкий ассортимент продукции, включая линейные датчики перемещения LVDT, датчики проволочного натяжения, датчики нагрузки, датчики LVDT, а также датчики крутящего момента, давления, магнитные датчики и многие другие. Мы предлагаем поддержку OEM/ODM в зависимости от потребностей клиента.

Мы обеспечиваем безопасную упаковку для всех продуктов и быструю доставку в течение 2 дней для товаров со склада. Доступно несколько вариантов транспортировки на выбор клиента. Информация о трекинге будет предоставлена после отправки вашего заказа.