Have you ever considered how engineers measure the distance that something moves? It’s pretty interesting! In engineering, an LVDT displacement sensor is a useful tool for engineers when they need to determine how far the object has moved. LVDT means Linear Variable Differential Transformer and it may too hi-tech, however let's unpack this.

An LVDT is a type of sensor, similar to an encoder in that it tells us about the position or movement of something. More specifically, this sensor is good at measuring how much an object moves. Displacement refers to the distance an object hasmoved from where it began. For instance, just thought of a pencil sitting on your desk. If you slide your pencil over from one side of a notebook to the other, then it is displaced. The rest is just how much has it moved!

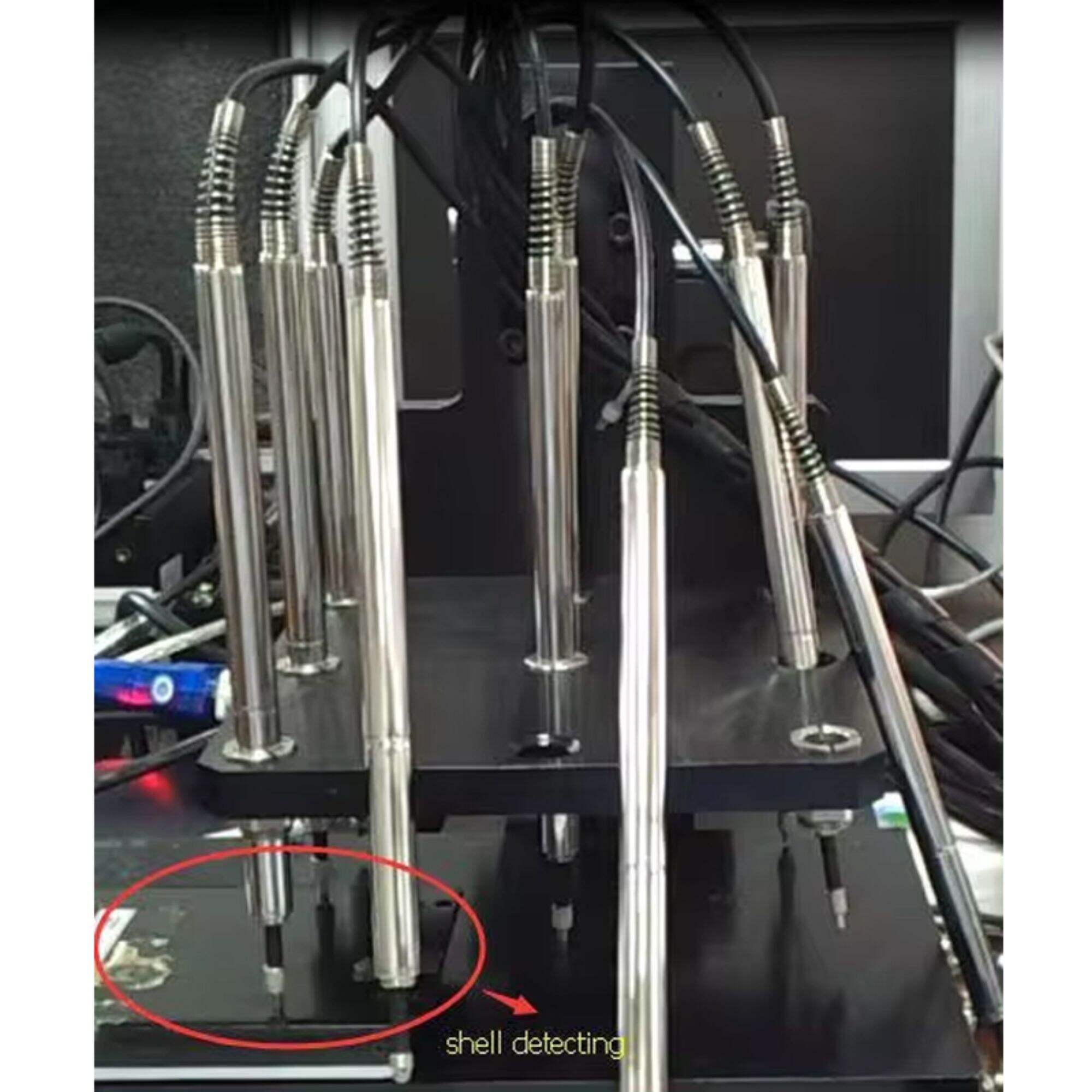

The basic LVDT working principle is shown in the figure. One special thing about the LVDT is that it can be used to measure without contacting with measured object. This indicates it will absolutely not disrupt the product. It does not rely on physical contact but has a magnetic field which identifies the position of object. When an LVDT is constructed, a tube will be wound with wire and hasone other metal piece that can fit snuglywithin the actualtube.

The electrical power going through the coil of wire results in a magnetic subject. The metal piece moves in and out of the tube; this changes the magnetic field. Such changes are detected by a clever device called as the LVDT. It then converts this magnetic field change in an electric signal. It can display this electric signal on a computer screen and instead of an input device, it is used in many other places as well by engineers or scientists.

The sensitivity of the LVDT is a great virtue This means it can detect even the smallest difference in which way an object is pointing. Operating on the same principle, this means it can detect things that others sensors might miss due to their insensitivity. For example, parts that are moving inside a machine, which might be of great importance when we try to ensure everything is really working just perfect!

The LVDT serves its purpose as a very versatile device and can be used under many different conditions. For example, it can verify the placement of an element in a car engine, or ensure that a valve is properly attached in place on pipe--or even see whether there's fastener missing from the wing of an airplane. These are just some of the examples how versatile LVDT applications can be across industries.

The LVDT also serves as the basic necessity for their experiments by scientists. In a laboratory, scientists could employ an LVDT conquest to gauge alterations in the shape of some rock on the several years or trace how fluid flows within a controlled environment. That also makes the LVDT a critical instrument in scientific research format as well.

We are accredited CE, RoHS and ISO9001. We make that each product undergoes rigorous inspection prior shipping. Additionally, SOP has professional lvdt displacement sensor after-sales assistance for product problems, as well as other problems.

SOP has over 20 years production expertise collaborated over 500 global customers. It a professional manufacturing high-tech business that is engaged in the research, development manufacturing, lvdt displacement sensor and service of various types of sensors.

We provide a broad range products, including linear lvdt displacement sensor sensors drawn wire sensors, load cells, LVDT sensors well as torque Senors, pressure sensors, magneto sensors, many more. We offer OEM/ODM support depending on the needs of client.

We provide lvdt displacement sensor safe packaging for all products quick shipping time of 2 days for stock goods There several kinds of transportation options available the customer to select. Tracking information will provided following the delivery of your goods.