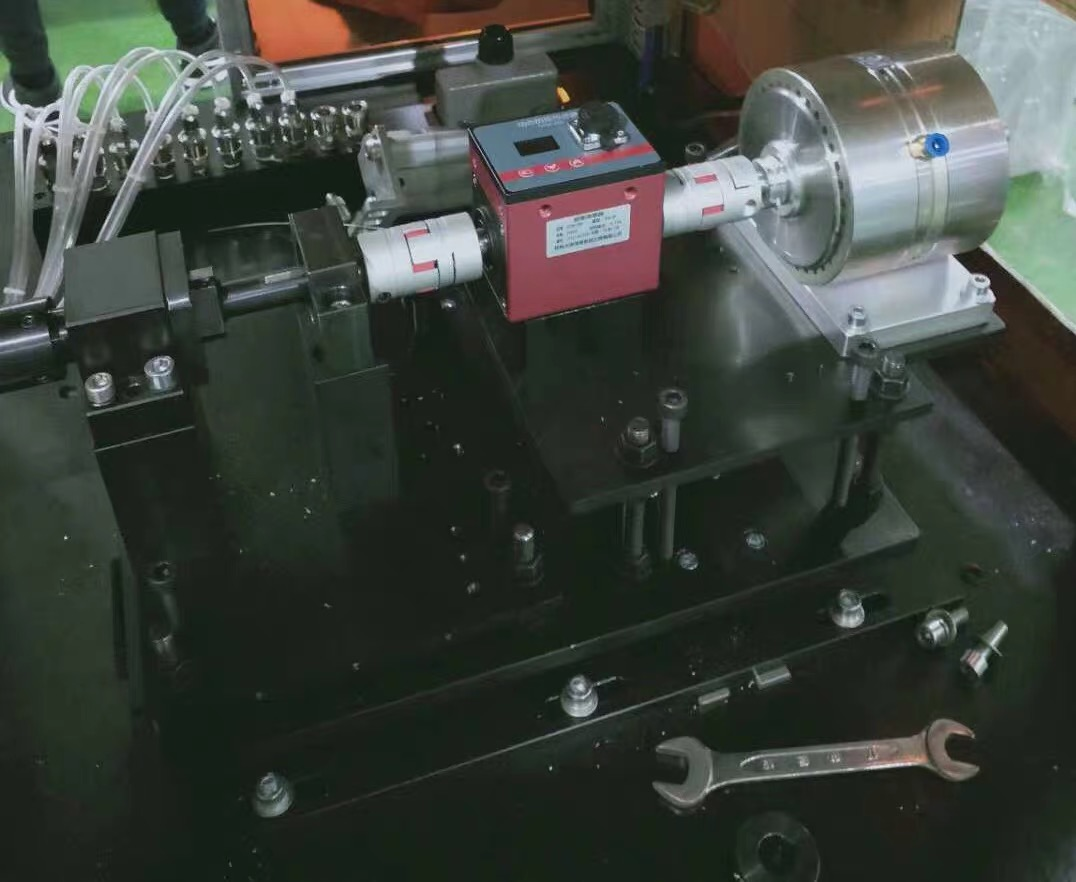

torque transmitter

A torque transmitter is a sophisticated measuring instrument designed to accurately measure and transmit torque data in rotating systems. This critical device serves as a bridge between mechanical power transmission and digital monitoring systems, providing real-time measurements of rotational force. The device consists of precision strain gauges mounted on a rotating shaft, which detect microscopic deformations caused by applied torque. These deformations are converted into electrical signals, which are then processed and transmitted to monitoring systems. Modern torque transmitters incorporate advanced features such as non-contact signal transmission, digital signal processing, and high sampling rates, ensuring reliable and accurate measurements even in demanding industrial environments. The technology finds extensive applications across various industries, including automotive testing, power generation, marine propulsion systems, and industrial machinery. The ability to measure torque continuously during operation enables predictive maintenance, performance optimization, and quality control in manufacturing processes. With measurement accuracies typically ranging from 0.1% to 0.5% of full scale, torque transmitters provide the precision required for both research and industrial applications. The integration of smart features such as temperature compensation and overload protection ensures consistent performance across varying operating conditions.