لماذا تعتبر أجهزة استشعار الموضع الخطي ضرورية في أنظمة الهيدروليك والهوائي

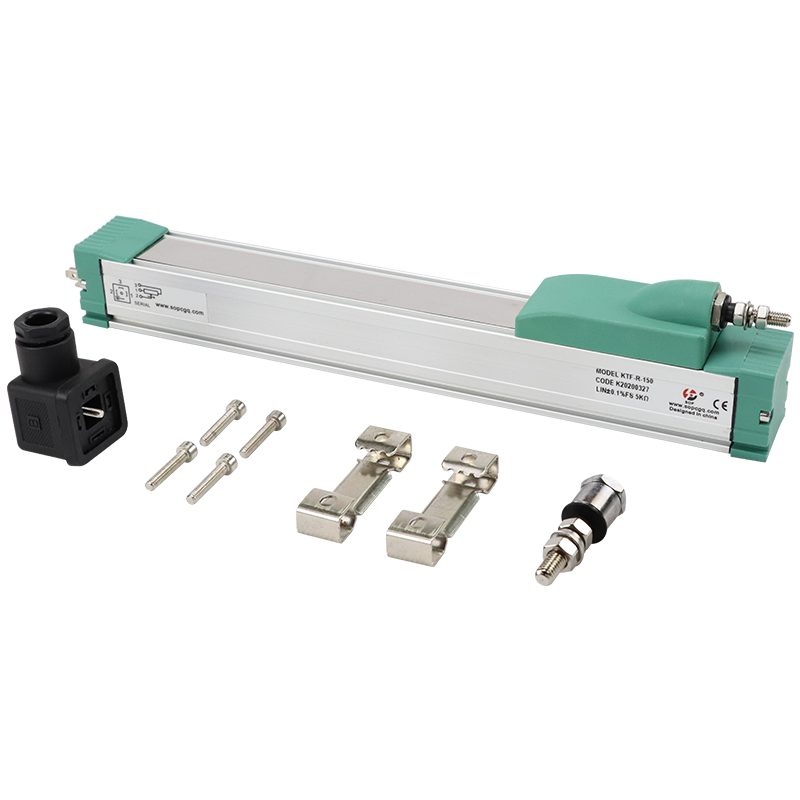

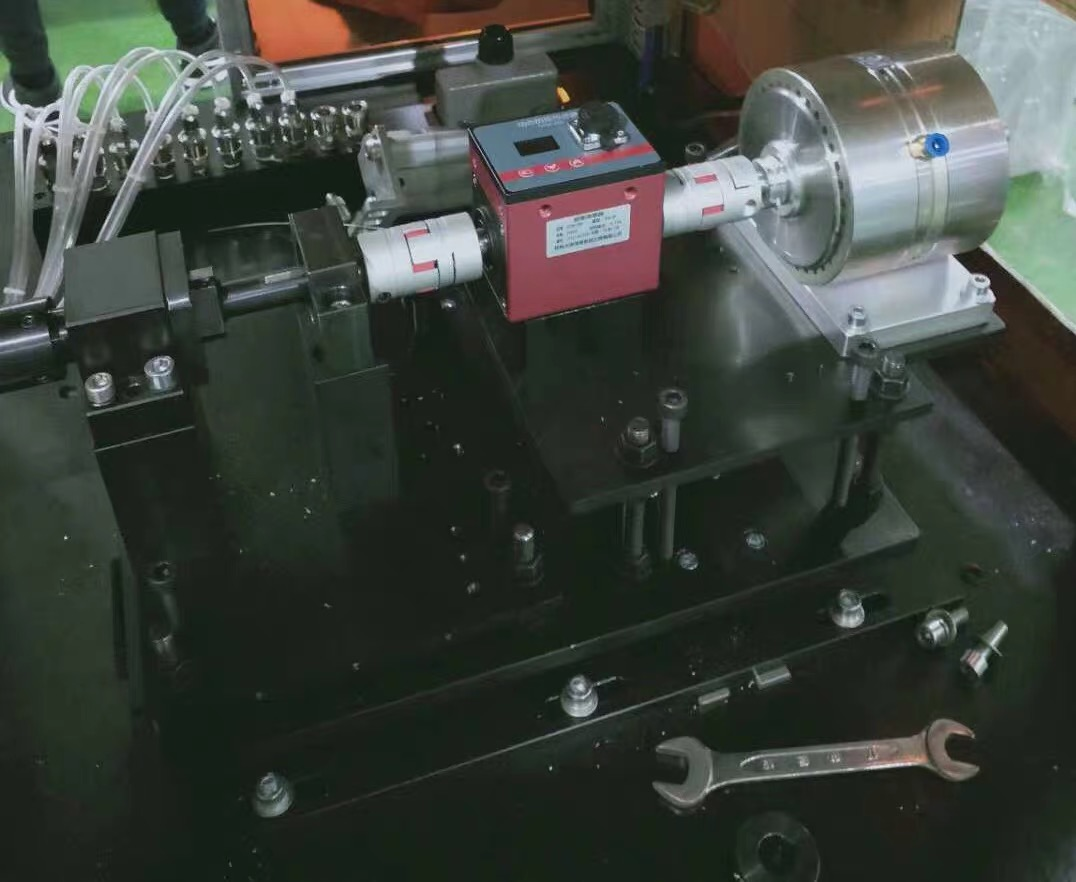

أجهزة استشعار الموضع الخطي هي مكونات أساسية في مجموعة متنوعة من التطبيقات الصناعية، خاصةً في الأنظمة الهيدروليكية والهوائية. تقوم هذه الأجهزة بقياس موقع الجسم المتحرك على خط مستقيم، مما يوفر معلومات دقيقة للردود الفعل...

عرض المزيد