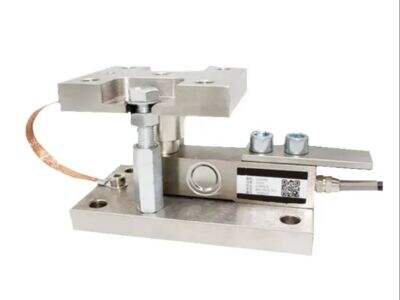

shaft torque transducer

A shaft torque transducer is a sophisticated measurement instrument designed to accurately measure and monitor the rotational force or torque applied to a rotating shaft. This essential device combines precision engineering with advanced sensing technology to provide real-time torque measurements in various industrial applications. The transducer operates by utilizing strain gauge technology, which detects microscopic deformations in the shaft caused by applied torque. These deformations are converted into electrical signals that are proportional to the torque being measured. Modern shaft torque transducers incorporate built-in signal conditioning and digital processing capabilities, enabling highly accurate measurements across a wide range of torque values. The device can be integrated into existing systems through various mounting configurations and offers multiple output options including analog, digital, and wireless transmission of measurement data. In industrial settings, these transducers play a crucial role in monitoring power transmission systems, testing engines and turbines, and ensuring optimal performance of rotating machinery. The technology has evolved to include features such as temperature compensation, overload protection, and advanced calibration capabilities, making it an indispensable tool for quality control, research and development, and process optimization.