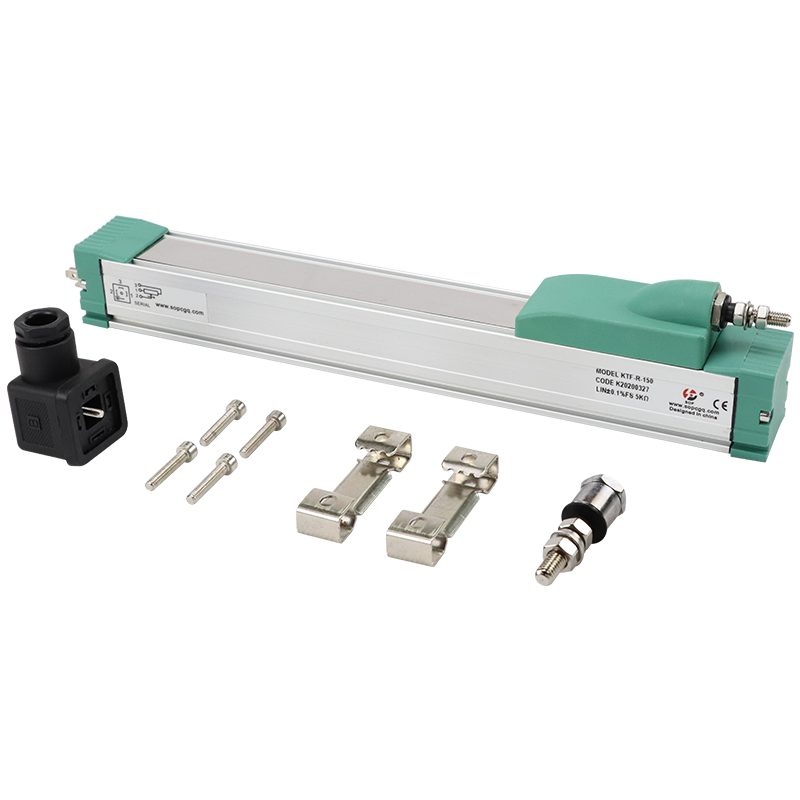

linear displacement transducer manufacturer

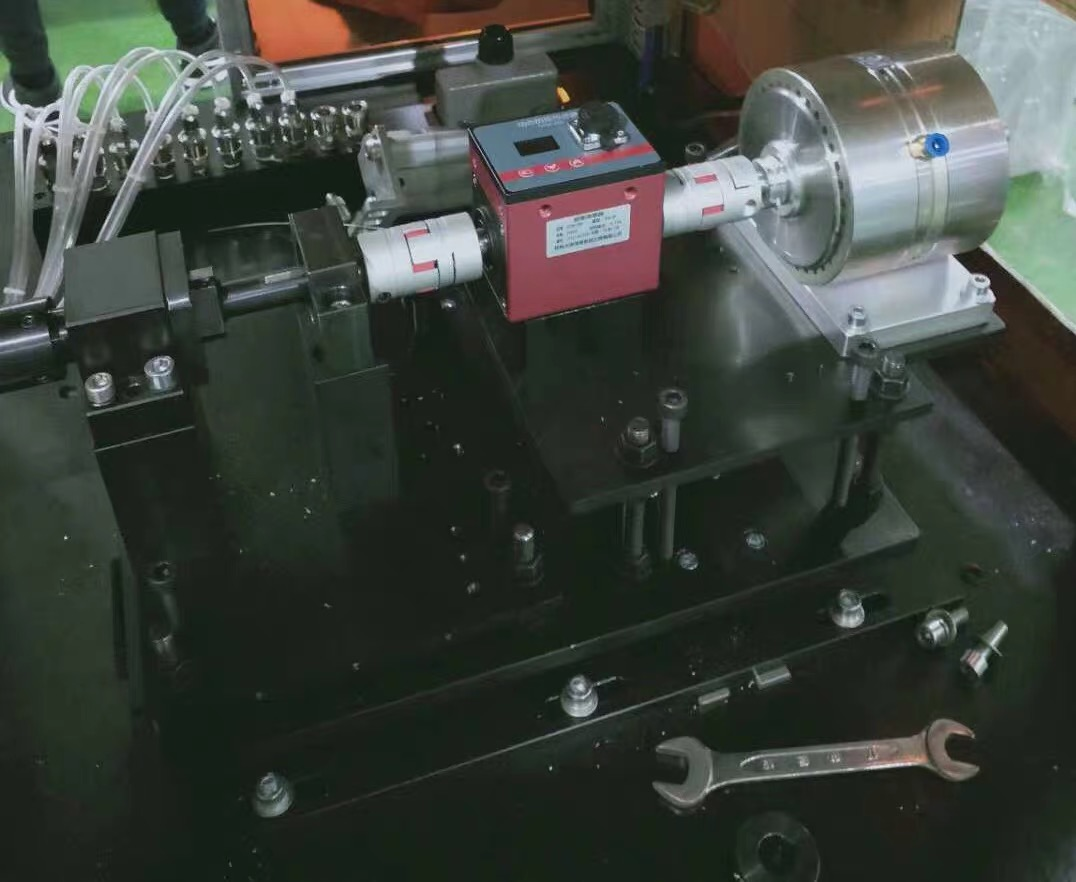

A linear displacement transducer manufacturer specializes in designing and producing high-precision measurement devices that convert mechanical motion into electrical signals. These sophisticated instruments are essential for modern industrial automation and quality control processes. The manufacturer employs cutting-edge technology to create sensors that accurately measure linear movement, position, and displacement in various applications. Their production facilities incorporate advanced manufacturing techniques, quality control systems, and rigorous testing protocols to ensure consistent product performance. The manufacturer's expertise extends to developing custom solutions for specific industry requirements, from automotive testing to aerospace applications. They utilize state-of-the-art materials and components to enhance durability and reliability while maintaining measurement accuracy. The manufacturing process includes precision engineering, automated assembly lines, and comprehensive quality assurance measures. Their products typically feature robust construction for industrial environments, multiple output options for various control systems, and advanced calibration capabilities. The manufacturer also provides technical support, installation guidance, and maintenance services to ensure optimal performance throughout the product lifecycle. Their commitment to innovation is evident in their continuous research and development efforts, resulting in improved sensor technologies and expanded application possibilities.