Understanding Draw Wire Sensors in Automation Systems

Core Working Principle of Wire Sensors

Draw wire sensors, also known as string potentiometers, operate on the principle of linear displacement measurement. They achieve this by unwinding a wire attached to a moving object. As the object moves, the wire is drawn out from a spool within the sensor housing. This movement is then translated into an electrical signal, which can be processed further to determine the exact position and motion of the object with remarkable precision. Such a mechanism is invaluable in automation systems where precision tracking of movement is necessary. This electrical signal's accuracy is pivotal for applications requiring high precision and reliability, making draw wire sensors essential in various industries.

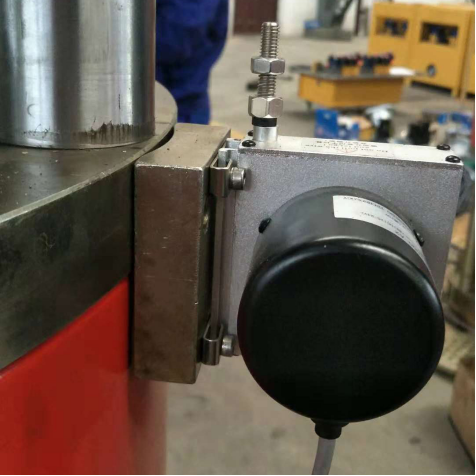

Key Components and Measurement Technology

The primary components of a draw wire sensor include the sensor housing, wire spool, and encoder. The encoder is responsible for converting the linear movement of the wire into an electrical signal correlating with the travel distance. Measurement technologies employed can vary, often involving potentiometric or non-contact methods to ensure high accuracy and long-term reliability. The choice between these methods can impact both the durability and response time of the sensor, critical factors in automation systems where consistent performance is required. By selecting the appropriate measurement technology, draw wire sensors can maintain their performance in challenging environments, ensuring optimal functionality in automated setups.

For more information on how these components contribute to the workings of draw wire sensors, you may want to explore how different sensor technologies like potentiometric or non-contact can influence their accuracy and application.

Precision Linear Measurement for Enhanced Automation

Achieving Sub-Millimeter Accuracy

Modern draw wire sensors achieve sub-millimeter precision, making them invaluable for precise applications like robotic surgery and automotive manufacturing. Such precision is backed by testing results, with specific models delivering a performance rate exceeding 99.9% according to an industry white paper. Sub-millimeter accuracy is crucial in automation processes requiring exact positioning for optimal performance and safety.

Reducing Manual Calibration Requirements

Draw wire sensors are largely self-calibrating, drastically reducing manual adjustment needs. This feature significantly decreases downtime and labor costs associated with equipment calibration; case studies reveal up to a 40% reduction in maintenance time, as cited in an automation industry report. The self-calibrating ability ensures operational efficiency and reliability in dynamic environments, as these sensors continuously adjust to maintain optimal functionality.

Space Efficiency in Industrial Applications

Compact Design for Confined Installations

The compact design of draw wire sensors is pivotal for installations in confined spaces. Unlike traditional sensors, these have a streamlined profile that allows them to fit into areas with limited space, facilitating easy integration into existing machinery. This is particularly useful in industrial environments where maximizing space is crucial. The versatile nature of these sensors makes them suitable for various applications ranging from complex manufacturing systems to intricate monitoring setups. Their compact form does not compromise on performance, as they manage to contribute efficiently to overall system efficiency. Such a design further underscores the importance of draw wire sensors in advancing industrial automation by providing solutions that are both space-effective and high-performing.

Integration in Robotics and Tight Machinery Spaces

Draw wire sensors are increasingly vital in robotics due to their ability to handle space constraints while providing precise movement tracking. These sensors integrate seamlessly with robotic arms and within tight machinery spaces without necessitating extensive modifications. This offers a tangible advantage, particularly where precision and space efficiency are of utmost importance. Industry reports highlight that utilizing these sensors results in smoother operations and enhanced robotic functionality, as noted in a recent study published in a top-tier robotics journal. By supporting intricate movement tracking and reducing space-related limitations, draw wire sensors significantly enhance both the operational capacity and the overall performance of robotic and machinery setups.

Real-Time Feedback for Operational Control

Continuous Position Data Streaming

Draw wire sensors play a pivotal role in continuous data streaming, which is essential for real-time monitoring and control in various automation systems. This capability allows operators to respond instantaneously to changes, ensuring seamless operation and minimizing disruptions. Real-time feedback is particularly critical in precision-driven industries like aerospace and automotive. Case studies in these sectors emphasize the importance of constant data flow to maintain precision and reliability in operations.

Dynamic Process Adjustments Through Sensor Input

The data gathered from draw wire sensors enables dynamic process adjustments, offering the flexibility needed to enhance productivity. In automated systems, real-time sensor input allows for instant recalibration, a valuable asset in environments where conditions frequently change. For example, manufacturing analysis indicates that integrating these sensors into production processes can result in a throughput increase of nearly 25%. This increase is attributed to the systems' ability to adapt quickly, ensuring optimal performance and efficiency.

Critical Applications Across Industries

Robotics: Precision Movement Control

In robotic applications, draw wire sensors are pivotal for achieving precision movement control. These sensors enable robots to perform delicate and complex tasks by providing accurate real-time feedback about their position. The continuous feedback loops offered by draw wire sensors ensure that robotic movements are executed with high fidelity, minimizing errors and enhancing overall reliability. This precision is vital in diverse applications, from robotic arms used in assembly lines to precise machinery in scientific laboratories. The use of such sensors in robotics underscores their importance in improving operational efficiency and accuracy.

Logistics: Conveyor Positioning Systems

Draw wire sensors are extensively used in logistics, particularly for conveyor positioning systems. They play a crucial role in ensuring the accurate tracking of goods throughout the supply chain, which is integral to maintaining an efficient logistical operation. These sensors can adeptly manage various load sizes and adjust to differing conveyor speeds, significantly improving operational efficiency. According to a logistics performance report, integrating draw wire sensors into logistics systems can boost throughput by as much as 30%, illustrating their significant impact on enhancing supply chain efficacy.

Industrial Automation: Heavy Machinery Guidance

In industrial automation, draw wire sensors are indispensable for guiding heavy machinery, ensuring safe and precise operations in environments that can pose significant hazards. These sensors provide critical data that empower operators to make informed decisions regarding the operation and maintenance of machinery. By integrating draw wire sensors into the frameworks of heavy machinery, companies can reduce operational risks considerably. Safety assessments have shown that such integration is crucial for maintaining safe operational standards, proving the efficacy of draw wire sensors in industrial settings. The real-time data they offer is paramount for optimizing processes and ensuring the well-being of operators working with heavy machinery.

FAQ Section

What are draw wire sensors?

Draw wire sensors, also known as string potentiometers, are devices used to measure linear displacement by unwinding a wire attached to a moving object. The movement is translated into an electrical signal for accurate position tracking.

How do draw wire sensors work in automation systems?

They function by providing precise movement tracking, making them essential in automation systems that require accuracy and reliability for optimal performance and safety.

What are the key components of draw wire sensors?

The main components include the sensor housing, wire spool, and encoder, which convert the wire's linear movement into an electrical signal correlating with travel distance.

What industries benefit from draw wire sensors?

Industries like robotics, logistics, and industrial automation benefit greatly, utilizing these sensors for precision control, efficient operations, and guiding heavy machinery safely.