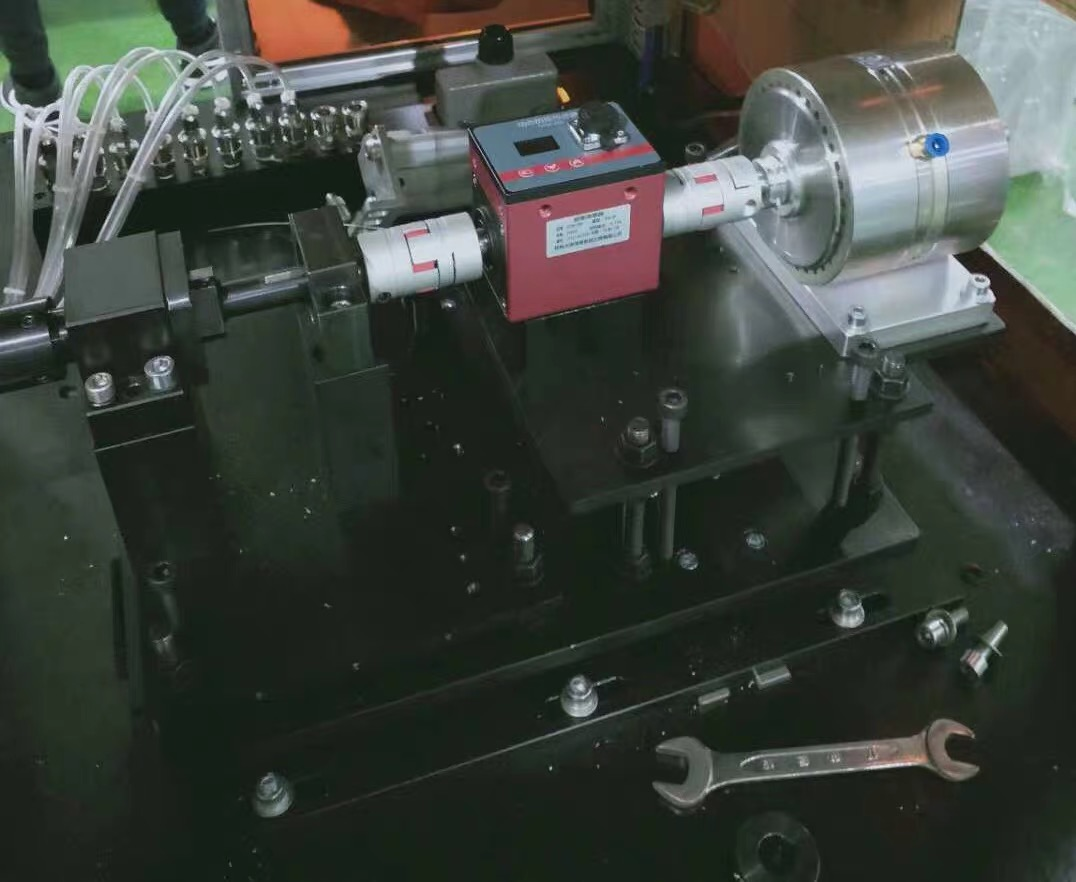

customized linear displacement transducer

A customized linear displacement transducer represents a sophisticated measurement instrument designed to precisely monitor and measure linear motion or position changes in various industrial applications. This advanced sensor technology converts mechanical displacement into proportional electrical signals, offering exceptional accuracy and reliability in position feedback systems. The device incorporates high-precision components and can be tailored to specific requirements, including measurement range, output signal type, and environmental protection levels. Operating through electromagnetic induction or magnetostrictive principles, these transducers provide continuous position feedback with resolutions down to micrometers. The customization options extend to mounting configurations, electrical connections, and signal processing capabilities, making them versatile solutions for diverse industrial applications. These transducers excel in demanding environments, featuring robust construction and protection against environmental factors such as dust, moisture, and electromagnetic interference. The integration capabilities with modern control systems and Industry 4.0 platforms make them essential components in automated manufacturing processes, quality control systems, and precision machinery.