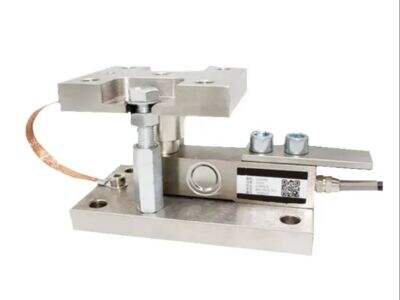

linear displacement sensor made in china

Linear displacement sensors made in China represent a significant advancement in precision measurement technology, offering reliable solutions for various industrial applications. These sensors, designed and manufactured to meet international standards, provide accurate measurements of linear motion and position changes. The core functionality involves converting mechanical displacement into electrical signals, enabling real-time monitoring and control of linear movement. These devices typically feature robust construction with high-quality materials, ensuring durability in demanding industrial environments. The technology employs various sensing principles, including magnetostrictive, potentiometric, and optical methods, delivering resolution accuracy down to micrometers. Chinese manufacturers have integrated advanced features such as digital output options, multiple interface protocols, and temperature compensation mechanisms. These sensors operate effectively across a wide temperature range and offer excellent repeatability and linearity. Applications span across multiple industries, including automotive manufacturing, robotics, hydraulic systems, and automated production lines. The sensors support various measurement ranges, typically from a few millimeters to several meters, making them versatile for different industrial needs. They also incorporate protection features against environmental factors such as dust, moisture, and electromagnetic interference, ensuring reliable operation in challenging conditions.