linear displacement sensor factory

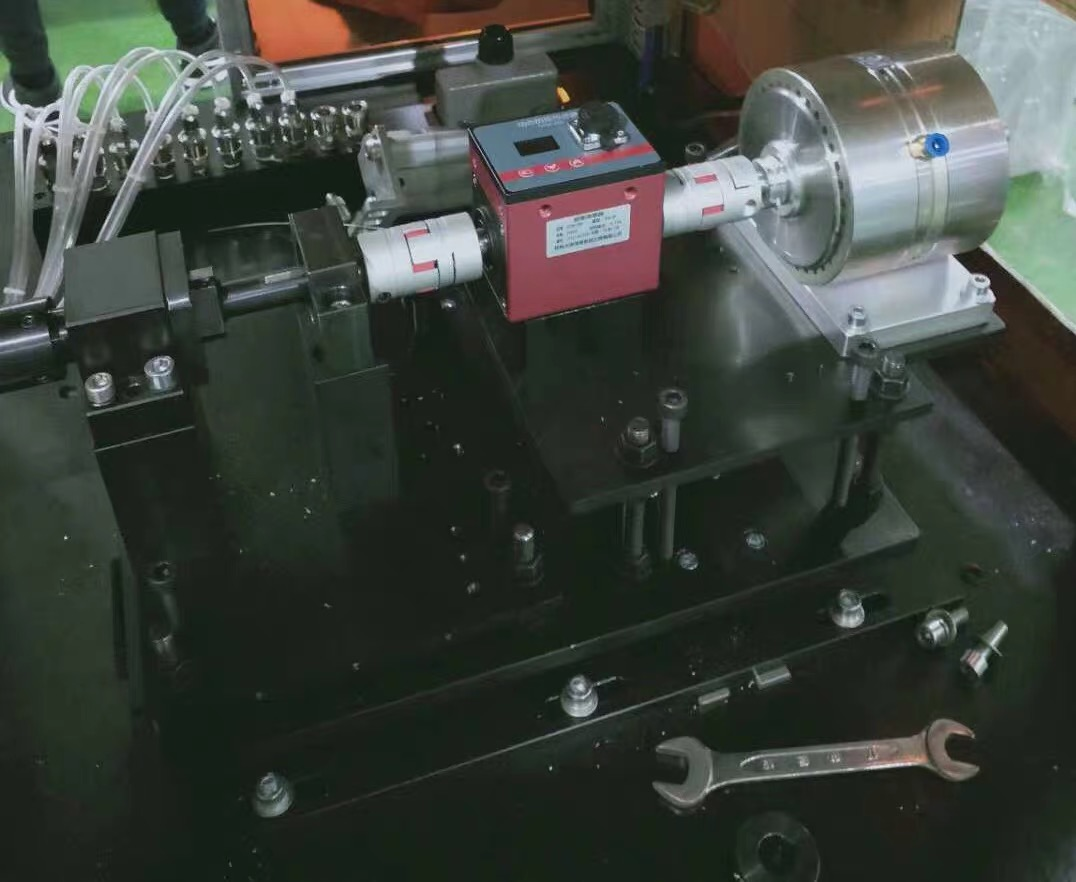

The linear displacement sensor factory stands as a cutting-edge manufacturing facility dedicated to producing high-precision measurement devices. Operating with state-of-the-art equipment and advanced manufacturing processes, the facility specializes in developing sensors that accurately measure linear movement and position changes in various industrial applications. The factory implements automated production lines equipped with quality control stations at every critical phase, ensuring consistent product excellence. The manufacturing process incorporates precision engineering techniques, utilizing advanced materials and sophisticated calibration systems to create sensors with exceptional accuracy and reliability. The facility's production capabilities extend from standard linear displacement sensors to customized solutions, accommodating diverse industrial requirements. With a focus on innovation, the factory maintains dedicated research and development departments that continuously work on improving sensor technology and developing new measurement solutions. The facility's comprehensive testing laboratories ensure that each sensor meets stringent quality standards and international certifications. Environmental control systems maintain optimal conditions for sensitive component assembly, while skilled technicians oversee critical manufacturing stages. The factory's integrated supply chain management ensures efficient material sourcing and product distribution, supporting timely delivery to global markets. This modern facility also emphasizes sustainable manufacturing practices, implementing energy-efficient processes and waste reduction measures throughout its operations.