buy linear displacement sensor

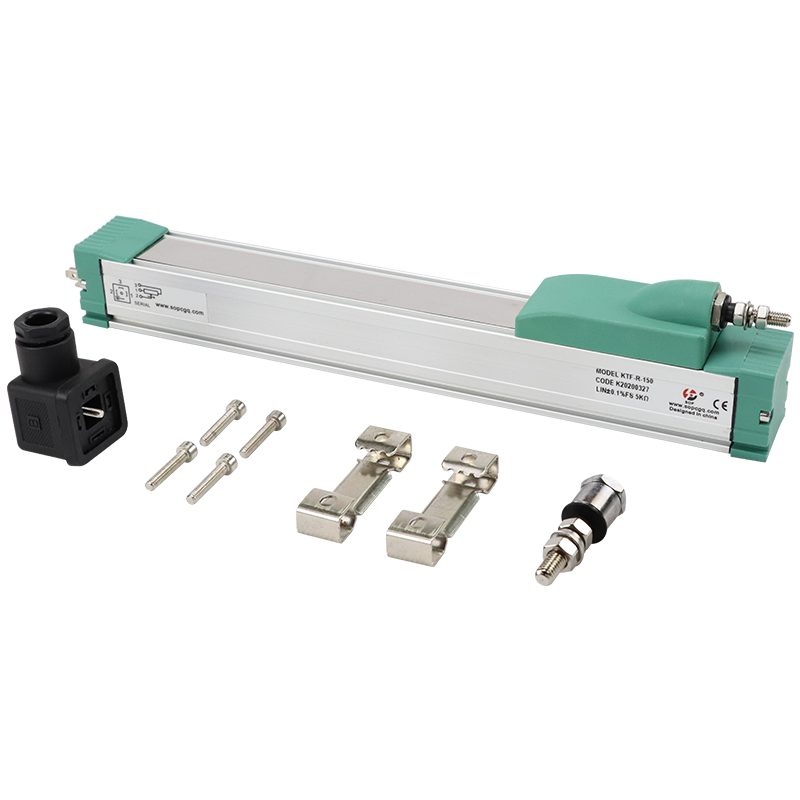

A linear displacement sensor is a sophisticated measurement device designed to accurately detect and measure linear motion or position changes along a single axis. These sensors convert mechanical displacement into an electrical signal, providing precise position feedback in various industrial and automation applications. The sensor typically consists of a sensing element, signal conditioning circuitry, and an output interface. Modern linear displacement sensors utilize various technologies including potentiometric, magnetostrictive, and optical principles to achieve high accuracy and reliability. They offer measurement ranges from a few millimeters to several meters, with some models capable of achieving resolution down to micrometers. These sensors are engineered to operate in challenging industrial environments, featuring robust construction and protection against dust, moisture, and electromagnetic interference. They provide real-time position monitoring and feedback, making them essential components in automated manufacturing systems, quality control processes, and precision machinery. The sensors can be integrated with various control systems through standard output signals, including analog voltage, current outputs, or digital interfaces, enabling seamless integration into existing industrial networks and control architectures.