linear displacement sensor vendors

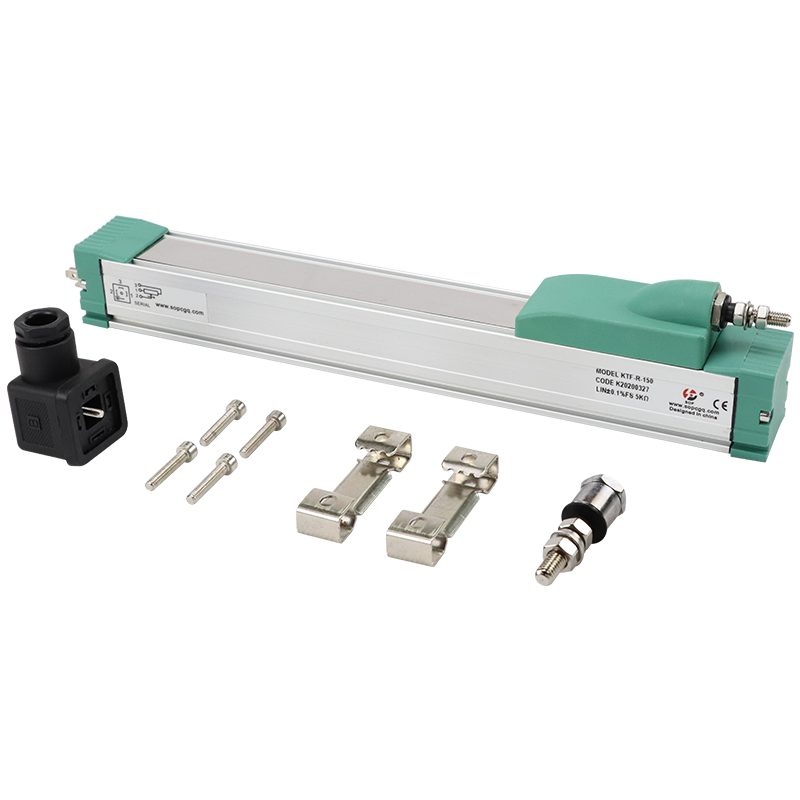

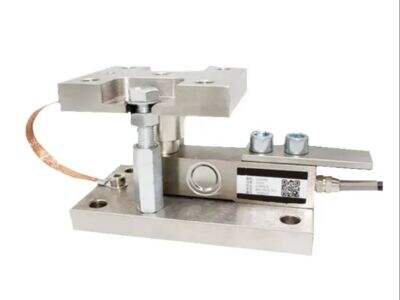

Linear displacement sensor vendors play a crucial role in providing advanced measurement solutions across various industries. These vendors offer sophisticated sensors that accurately measure linear movement or position changes in mechanical systems. Their product portfolios typically include both contact and non-contact sensors, utilizing various technologies such as magnetostrictive, potentiometric, and optical measurement principles. These vendors not only supply the hardware but also provide comprehensive support services, including calibration, maintenance, and technical consultation. Leading vendors in this space continually invest in research and development to enhance sensor accuracy, durability, and integration capabilities. They offer sensors with different measurement ranges, from microscopic measurements to several meters, catering to diverse industrial applications. Many vendors now incorporate smart features such as digital outputs, IoT connectivity, and real-time monitoring capabilities in their sensors. These companies also ensure their products meet international standards and certifications, providing reliable solutions for automation, quality control, and precision manufacturing processes. The vendor ecosystem includes both specialized sensor manufacturers and larger industrial automation companies, offering customers various options in terms of technical specifications, price points, and after-sales support.