proizvodnja linearnih senzorjev za določanje položaja

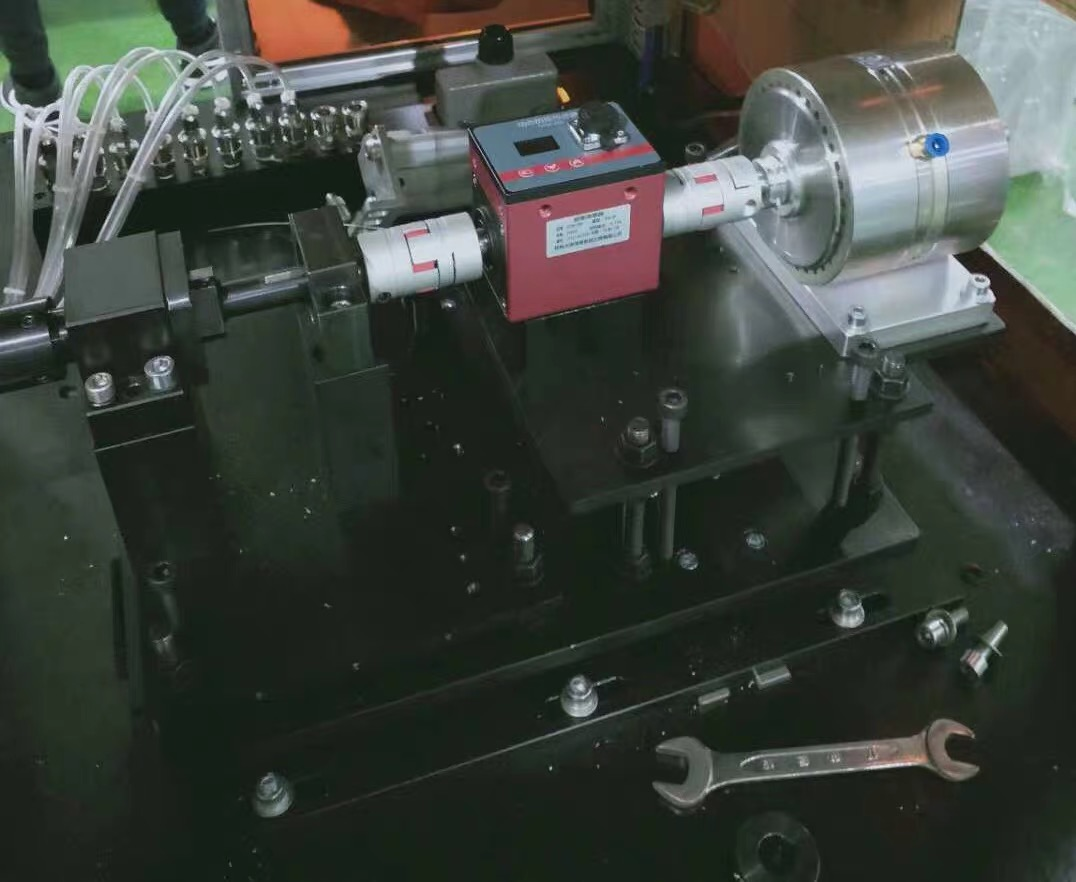

Tovarna za linearna senzorja lega predstavlja sodobno proizvodno obrat, ki je namenjena izdelavi visoko natančnih naprav za merjenje linearne pomik in lego v različnih industrijskih uporabah. Obrat združuje napredne avtomatske sisteme, procese kontrole kakovosti ter najnovejšo preskusno opremo, da zagotovi proizvodnjo zanesljivih in točnih senzorjev. Te proizvodne enote uporabljajo sofisticirane čiste prostore, avtomatske sestavne linije in natančne kalibracijske postaje za ohranjanje enotne kakovosti izdelkov. Tovarna uveljavlja stroga sistema upravljanja s kakovostjo, vključno s standardi ISO certifikacij, da zagotovi, da vsak senzor ustrezni določenim zmogljivostnim zahtevam. Sodobne tovarne za linearna senzorja lega vključujejo pametna proizvodna načela, pri čemer uporabljajo IoT senzorje in analizo podatkov za optimizacijo proizvodnih procesov in ohranjanje kontrole kakovosti. Vsebujejo specializirano opremo za različne tehnologije senzorjev, vključno z magnetostruktivnimi, optičnimi, kapacitivnimi in induktivnimi senzorskimi rešitvami. Ohranja tudi oddelke za raziskave in razvoj, ki se osredotočajo na inovacije novih senzorskih tehnologij in izboljšave obstoječih konstrukcij. Sistemi za nadzor okolja regulirajo temperaturo, vlažnost in raven prahu, da zagotovijo optimalne proizvodne pogoje. Preskusne enote tovarne vključujejo okoljske komore, opremo za testiranje življenjske dobe ter natančne meritve orodja za validacijo delovanja senzorjev v različnih pogojih.