linear position sensor factory

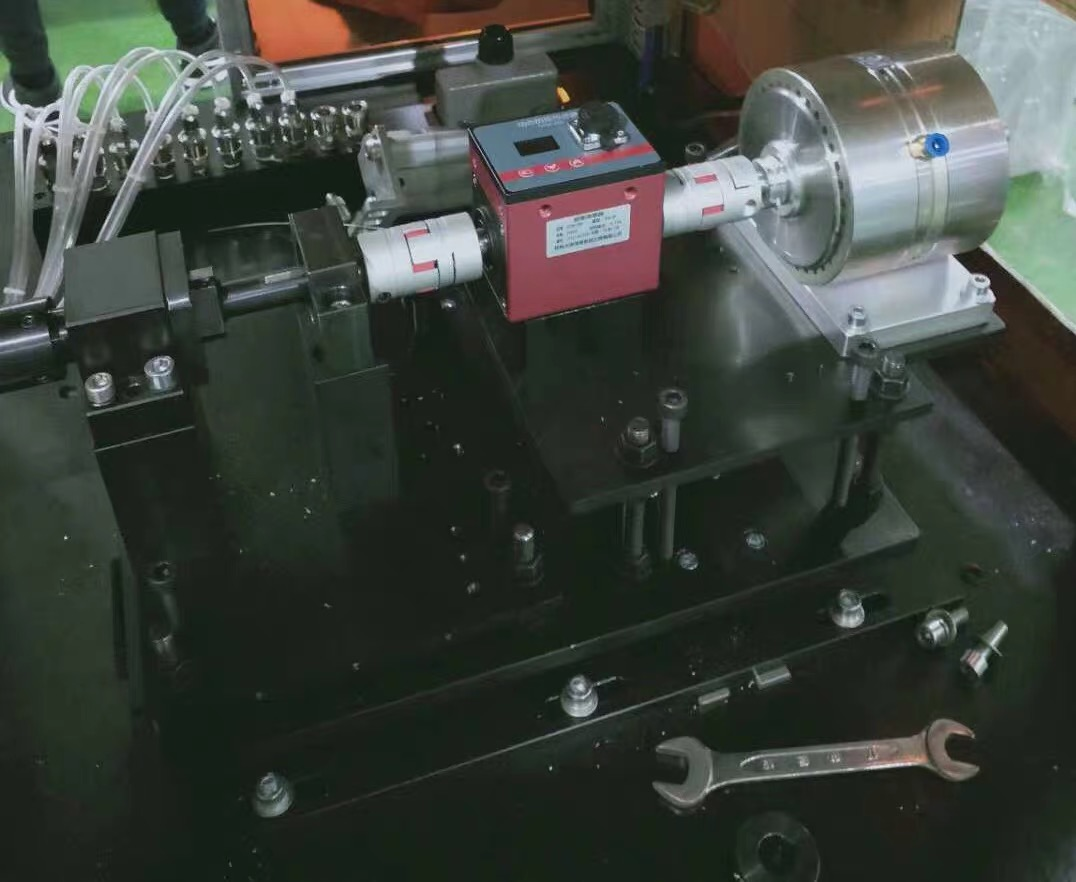

A linear position sensor factory represents a cutting-edge manufacturing facility dedicated to producing high-precision devices that measure linear displacement and position in various industrial applications. The facility combines advanced automation systems, quality control processes, and state-of-the-art testing equipment to ensure the production of reliable and accurate sensors. These manufacturing plants utilize sophisticated clean rooms, automated assembly lines, and precision calibration stations to maintain consistent product quality. The factory implements strict quality management systems, including ISO certification standards, to guarantee that each sensor meets specific performance requirements. Modern linear position sensor factories integrate smart manufacturing principles, employing IoT sensors and data analytics to optimize production processes and maintain quality control. They house specialized equipment for different sensor technologies, including magnetostrictive, optical, capacitive, and inductive sensing solutions. The facility also maintains dedicated research and development departments focused on innovating new sensor technologies and improving existing designs. Environmental control systems regulate temperature, humidity, and dust levels to ensure optimal manufacturing conditions. The factory's testing facilities include environmental chambers, lifecycle testing equipment, and precision measurement tools to validate sensor performance under various conditions.