Hast du dich jemals gefragt, wie wir eigentlich wissen, dass Dinge ein Gewicht haben? Es ist irgendwie ein Rätsel, und wir lösen es mit einem ganz besonderen Werkzeug... dem Wägezellen-Wandlern! A LASTZELLE : Ein zuverlässiger Begleiter Misst einfach das Gewicht eines Gegenstands mit äußerster Genauigkeit, bis auf das letzte Gramm genau, wie viel eine Person oder etwas wiegt. Wir verwenden Gewicht, um im Alltag viele Dinge zu messen, beispielsweise Zutaten beim Kochen leckerer Mahlzeiten, Gepäck in einem Flugzeug, damit man weiß, wie schwer es ist und ob das Flugzeug noch fliegen kann, oder sogar Tiere wie Elefanten im Zoo! Wägezellen, diese dienen als Gewichtssensoren, die uns dabei helfen, die genauestmögliche Messung zu erhalten.

LASTZELLE wegtransmitter sind außerdem sehr langlebig und können eine lange Zeit verwendet werden. Die Technologie, die diese Werkzeuge nutzen, ist aufgrund ihrer Fähigkeit, enormes Gewicht zu tragen, ohne leicht zu brechen, wirklich erstaunlich. Das bedeutet, dass Sie diese Werkzeuge mehrfach wiederverwenden können, ohne dass sie abgenutzt werden, was viel Zeit und Geld spart. Zudem sind Lastzellen-Wegtransmitter stoß- und vibrationsresistent, wodurch sie in harten Umgebungen wie Fabriken mit viel Kollision oder Baustellen mit starker Erschütterung und Lärm eingesetzt werden können.

Eine der fantastischen Eigenschaften von Wägesensoren ist ihre Vielseitigkeit in der Anwendung. Beispielsweise können sie sich mit Computern verbinden und Grafiken erstellen, die Verläufe von Veränderungen im Laufe der Zeit veranschaulichen. Als druckerfähige Waagen können sie eine Vorrichtung besitzen, die das Gewicht von schweren Gegenständen ausdruckt. Dies kann besonders bei versandfähigen Produkten oder physischen Waren hilfreich sein. Schließlich werden sie auch zusammen mit anderen Maschinen eingesetzt, wie z.B. Förderbändern, wodurch das Wiegen von Objekten einfacher und schneller wird. Dies ermöglicht es Arbeitern, Gegenstände schnell und genau zu wiegen, ohne Produktionsverzögerungen zu verursachen. All diese Eigenschaften machen LASTZELLE wägesensoren für zahlreiche Aufgaben in verschiedenen Branchen einsetzbar.

Neben der Übertragung von hochgenauen Gewichtsmessungen von Lastzellen ermöglichen uns die darauf basierenden Gewichtstransmitter, diese Änderungen sofort zu beobachten, sobald sie unsere Behälter oder deren Umgebung beeinflussen. Das heißt, wir können die Veränderung des Gewichts eines Objekts beobachten, das sich von einem Ort an einen anderen bewegt. Zum Beispiel können Lastzellengewichtstransmitter in einer Fabrikproduktion die Produktgewichte überwachen, während sie sich entlang der Linie bewegen. Dies dient als guter Prüfpunkt für Arbeiter, um sicherzustellen, dass jedes Produkt das richtige Gewicht und die richtige Qualität hat. Diese Alarmeinstellungen können den Arbeitern auch helfen, Fehler frühzeitig zu erkennen, wobei Lastzellen einen Alarm auslösen, wenn ihr Gewicht zu stark schwankt. Es handelt sich um eine Echtzeitüberwachung, die essenziell ist, um einen reibungslosen Prozess aufrechtzuerhalten.

Das Wiegen von Objekten mit Wägesensoren wird zudem einfacher, schneller und gleichzeitig sicherer. LASTZELLE der Gewichtstransmitter eliminiert die Notwendigkeit, dass Arbeiter schwere Gegenstände manuell heben und handhaben müssen. Stattdessen können sie Maschinen wie Gabelstapler oder Förderbänder nutzen, um Dinge zu transportieren und gleichzeitig mit Hilfe von Lastaufnehmern das Gewicht zu messen. Dadurch bleibt der Prozess sicher und schnell, sodass die Arbeiter sich auf andere wichtige Tätigkeiten konzentrieren können. Lastaufnehmer-Gewichtstransmitter können auch als vorbeugende Maßnahme gegen Unfälle dienen, indem sie verhindern, dass Maschinen arbeiten, solange ein Objekt zu schwer für die sichere Bewegung des jeweiligen Elements ist. Kurz gesagt: Auch Sie können ganz einfach die Last von Waagemaschinen teilen und Ihre eigene Arbeitsumgebung sicher sowie geschützt gestalten, indem Sie verschiedene Arten von Lastaufnehmern an die richtigen Stellen oder an beliebige Plätze mittels drahtloser Verbindung installieren, die durch gängige Gewichtstransmitter | Wägesysteme gesteuert wird.

SOP hat über 20 Jahre Erfahrung im Fertigungssektor und arbeitet mit über 500 globalen Kunden zusammen. Es handelt sich um ein renommiertes Unternehmen, das hochtechnologische Produkte herstellt und als Lastzellengewichtstransmitter in Forschung, Entwicklung, Fertigung, Verkauf und Wartung verschiedener Sensoren tätig ist.

Kunden können aus einer Reihe von Transportdiensten auswählen. Wir bieten sichere Verpackung und schnelle Lieferung für alle Lagergüter. Nachverfolgungsinformationen können vom Lastzellengewichtstransmitter angezeigt werden, nachdem die Waren versandt wurden.

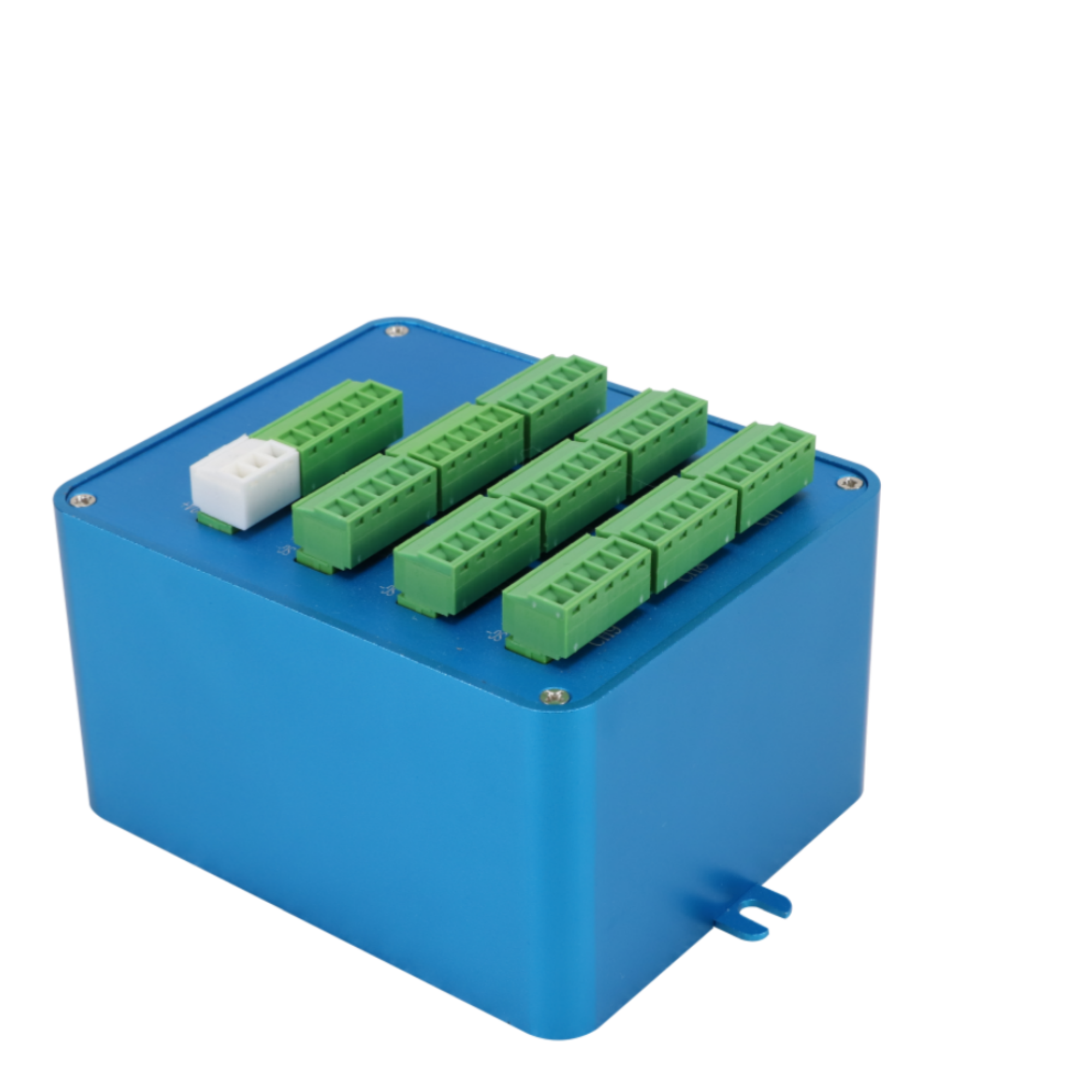

Unsere Hauptprodukte bestehen aus verschiedenen Arten von Sensoren, wie Linearspursensoren, Zugseilsensor, Lastwagen, LVDT-Drehmomentsensor, Magneto-Sensor, Lastwagensensor für Gewichtstransmitter und vielen mehr. Wir bieten OEM/ODM-Dienstleistungen entsprechend den Anforderungen der Kunden.

Unsere Firma wurde von CE, RoHS, ISO9001 sowie anderen Zertifizierungen akkreditiert. Vor der Verschiffung überprüfen wir jedes Produkt. SOP stellt außerdem Ingenieure zur Verfügung, die nach dem Verkauf Lastwagensensoren für Gewichtstransmitter bereitstellen, um Probleme mit dem Produkt zu lösen.