এস টাইপ লোড সেল বিভিন্ন শিল্প অ্যাপ্লিকেশনের জন্য লোড সেলগুলি গুরুত্বপূর্ণ উপাদান, বিশেষ করে ওজন এবং বল পরিমাপের জন্য। তাদের অনন্য ডিজাইন এবং কার্যপ্রণালী তাদের সঠিক এবং নির্ভরযোগ্য তথ্য প্রদান করতে দেয়, যা উৎপাদন থেকে শুরু করে গবেষণা পর্যন্ত অসংখ্য খাতে অপরিহার্য। আসুন S টাইপ লোড সেলগুলিকে এতটা কার্যকর করে তোলে সেই প্রযুক্তি সম্পর্কে আরও গভীরভাবে জানি।

1. নির্মাণ এবং ডিজাইন

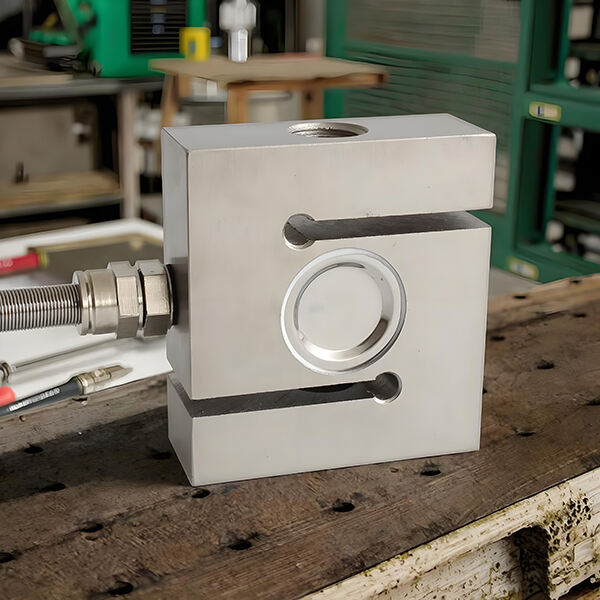

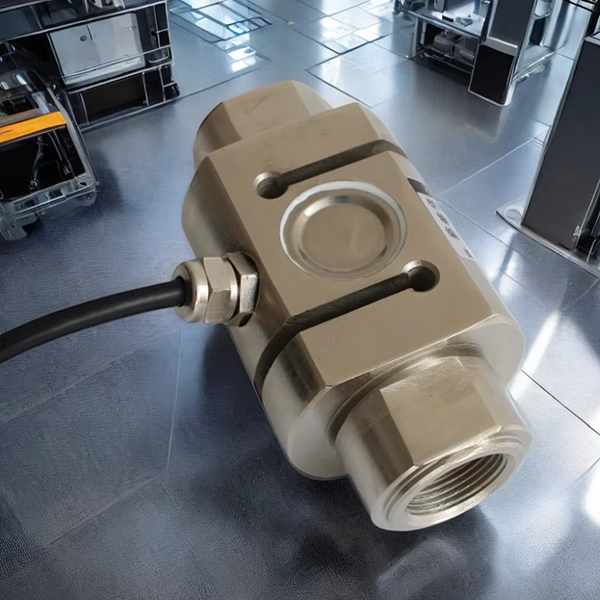

এস টাইপ লোড সেলগুলির ডিজাইন অক্ষর "এস" এর মতো দেখায়, যার নামকরণ এখান থেকে এসেছে। এই ডিজাইন বৈশিষ্ট্যটি কেবল সৌন্দর্যময় নয়; এটি তাদের কাজের ক্ষেত্রে গুরুত্বপূর্ণ ভূমিকা পালন করে। উচ্চ-শক্তির খাদ ইস্পাত বা অ্যালুমিনিয়াম দিয়ে তৈরি, এই লোড সেলগুলি শক্তিশালী এবং উচ্চ ধারণক্ষমতা সহ্য করতে সক্ষম, সাধারণত কয়েক পাউন্ড থেকে হাজার হাজার পাউন্ড পর্যন্ত।

দ্বৈত বেঞ্চিং বীম ব্যবস্থা তাদের টান এবং সংকোচন উভয়কেই সঠিকভাবে পরিমাপ করতে দেয়, যা বিভিন্ন অ্যাপ্লিকেশনের জন্য তাদের বহুমুখী করে তোলে। কমপ্যাক্ট ডিজাইনটি বিভিন্ন সেটআপে সহজে একীভূত করাও সহজ করে তোলে।

2. স্ট্রেইন গেজ প্রযুক্তি

একটি এস টাইপ লোড সেল এর কেন্দ্রে রয়েছে স্ট্রেইন গেজ, একটি গুরুত্বপূর্ণ উপাদান যা যান্ত্রিক বিকৃতিকে বৈদ্যুতিক সংকেতে রূপান্তরিত করে। স্ট্রেইন গেজগুলি লোড সেলের পৃষ্ঠের সাথে আঠালো থাকে, এবং ওজন প্রয়োগ করা হলে, উপাদানটি সামান্য বিকৃত হয়। এই বিকৃতি স্ট্রেইন গেজের বৈদ্যুতিক রোধে পরিবর্তন ঘটায়, যা পরিমাপ করা যায় এবং ওজনে রূপান্তরিত করা যায়।

উচ্চ-গুণমানের S টাইপ লোড সেলগুলিতে ব্রিজ কনফিগারেশনে সজ্জিত একাধিক স্ট্রেইন গেজ ব্যবহার করা হয়, যা সংবেদনশীলতা এবং নির্ভুলতা বৃদ্ধি করে। এই কনফিগারেশনটি লোড সেলের সম্পূর্ণ ক্ষমতা কার্যকরভাবে ব্যবহার করে এবং তাপমাত্রা পরিবর্তন এবং লোড বন্টনের কারণে ঘটা ত্রুটিগুলি কমিয়ে দেয়।

3. উচ্চ নির্ভুলতা এবং স্থিতিশীলতা

S টাইপ লোড সেলগুলি তাদের উচ্চ নির্ভুলতা এবং স্থিতিশীলতার জন্য বিখ্যাত। এগুলি ফুল-স্কেল লোডের 0.02% থেকে 0.1% এর মধ্যে নির্ভুলতা অর্জন করতে পারে, যা এমনকি সবচেয়ে চাহিদাপূর্ণ অ্যাপ্লিকেশনগুলির জন্যও উপযুক্ত করে তোলে। সময়ের সাথে সাথে তাদের স্থিতিশীলতা নিশ্চিত করে যে পুনরায় ক্যালিব্রেশনের প্রয়োজন ছাড়াই তারা নির্ভরযোগ্য পাঠগুলি দিতে থাকে।

অধিকন্তু, নকশাটি পার্শ্বীয় বলের প্রভাব কমাতে সাহায্য করে, পরিমাপের অখণ্ডতা বৃদ্ধি করে। এটি বিশেষ করে এমন পরিবেশে উপকারী যেখানে কোষের অক্ষ বরাবর সরাসরি লোড প্রয়োগ করা হয় না।

4. ডিজিটাল আউটপুট এবং একীভূতকরণ

আধুনিক এস টাইপ লোড সেল এগুলি প্রায়শই ডিজিটাল আউটপুট ক্ষমতা নিয়ে আসে। এই বৈশিষ্ট্যটি ডিজিটাল ডিসপ্লে এবং ডেটা অধিগ্রহণ ব্যবস্থার মতো বিভিন্ন ডিজিটাল ডিভাইস এবং ব্যবস্থার সাথে সহজ সংহতকরণের অনুমতি দেয়। অনেক মডেলে অন্তর্নির্মিত প্রবর্ধক থাকে যা স্ট্রেইন গেজ থেকে এনালগ সংকেতকে সরাসরি ডিজিটাল ফরম্যাটে রূপান্তর করে, পরিমাপের প্রক্রিয়াকে সরলীকৃত করে।

এই ডিজিটাল সংহতকরণ দূরবর্তী নিরীক্ষণ এবং আরও ভালো ডেটা ব্যবস্থাপনার মতো অতিরিক্ত সুবিধা প্রদান করে, যা আজকের পারস্পরিকভাবে সংযুক্ত শিল্প পরিবেশে ক্রমাগত গুরুত্বপূর্ণ হয়ে উঠছে।

৫. বিভিন্ন শিল্পে অ্যাপ্লিকেশন

S টাইপ লোড সেলগুলির বহুমুখিতা অর্থ হল যে এগুলি বিভিন্ন শিল্পে প্রয়োগ খুঁজে পায়। এগুলি সাধারণত ব্যবহৃত হয়:

শিল্প ওজন: উৎপাদন কারখানার স্কেলের জন্য।

উপকরণ পরীক্ষা: উপকরণ বিজ্ঞানে টেনসাইল শক্তি এবং বল পরিমাপের জন্য।

বল পরিমাপ: গবেষণা এবং উন্নয়ন ক্ষেত্রে।

লোড মনিটরিং: ক্রেন এবং উত্তোলন সরঞ্জামের জন্য, নিরাপত্তা এবং দক্ষতা নিশ্চিত করার জন্য।

এই প্রযুক্তির পেছনে S টাইপ লোড সেল , তাদের উদ্ভাবনী ডিজাইন থেকে শুরু করে সূক্ষ্ম স্ট্রেইন গেজ মেকানিজম পর্যন্ত, অনেক শিল্প প্রয়োগে তাদের অপরিহার্য সরঞ্জাম হিসাবে স্থাপন করে। টান এবং চাপ উভয়কেই সঠিকভাবে পরিমাপ করার তাদের ক্ষমতা তাদের বহুমুখী এবং নির্ভরযোগ্য করে তোলে, যা শিল্পগুলিকে কার্যকরভাবে এবং নিরাপদে কাজ করার জন্য গুরুত্বপূর্ণ তথ্য প্রদান করে। প্রযুক্তির অগ্রগতির সাথে, লোড সেলের ক্ষমতায় আরও উন্নতি আশা করা যায়, যা আধুনিক শিল্প পরিবেশে তাদের ভূমিকা আরও উন্নত করবে।