Where to Use Linear Displacement Sensor in Machinery?

In modern machinery, precision and accuracy are essential to ensure reliable operation, reduced downtime, and optimal performance. Many types of sensors are used to achieve this, but one that plays a particularly vital role in various mechanical applications is the Linear Displacement Sensor.

A Linear Displacement Sensor measures the movement of an object along a straight path, converting that motion into an electrical signal that can be monitored or recorded. These sensors are widely used in machinery for position measurement, automation, quality control, and process optimization. This article will explore the primary areas in which a Linear Displacement Sensor can be used in machinery, the benefits it brings, and the factors to consider for successful integration.

Understanding the Linear Displacement Sensor

A Linear Displacement Sensor is a device that detects and quantifies the linear motion or position of an object. It works by detecting changes in position and converting that change into a proportional electrical output. This information can then be fed into a control system for processing, display, or further action.

There are several types of Linear Displacement Sensors, each suited for different environments and applications:

Potentiometric Sensors: Use a resistive track and a moving contact to measure displacement.

LVDTs (Linear Variable Differential Transformers): Use electromagnetic induction for high accuracy and durability.

Magnetostrictive Sensors: Provide contactless measurement using magnetic fields.

Optical Sensors: Utilize light-based technology for high-resolution position tracking.

Capacitive Sensors: Detect changes in capacitance caused by displacement.

Each type of Linear Displacement Sensor has strengths and limitations, making them suitable for specific machinery applications.

Key Benefits of Using a Linear Displacement Sensor in Machinery

High Accuracy: Allows precise positioning and movement control.

Real-Time Feedback: Supports immediate adjustments for automated systems.

Durability: Many designs withstand harsh industrial environments.

Versatility: Suitable for different types of machinery and operating conditions.

Efficiency Improvement: Optimizes production speed without sacrificing quality.

Applications of Linear Displacement Sensors in Machinery

CNC Machines and Precision Manufacturing

In CNC (Computer Numerical Control) machines, a Linear Displacement Sensor plays a critical role in ensuring precise tool positioning. Even the smallest positional error can result in defective parts, especially in industries like aerospace, automotive, and medical device manufacturing.

Sensors in CNC machines measure tool head movement along the X, Y, and Z axes, allowing the control system to maintain extremely tight tolerances. LVDTs and optical sensors are common choices here because they provide high resolution and repeatability.

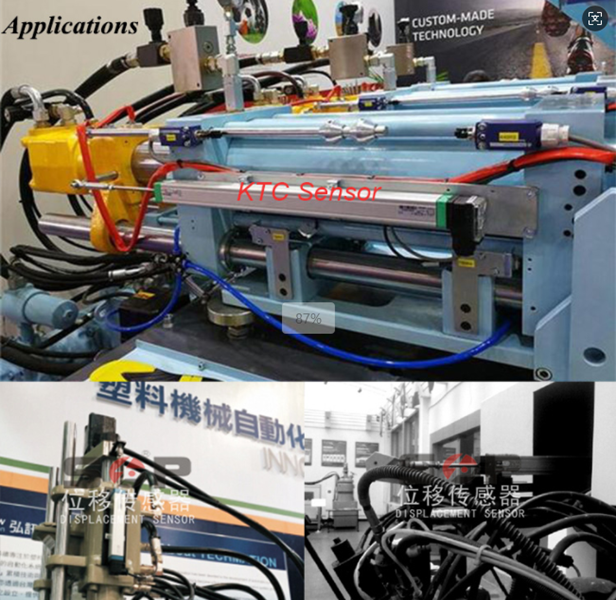

Injection Molding Machines

In plastic and metal injection molding, accurate control of mold position and injection stroke is essential. A Linear Displacement Sensor can track the movement of the injection screw or mold platen, ensuring consistent product quality. This is particularly important for mass production, where even slight deviations can lead to large volumes of defective products.

Robotics and Automated Assembly Lines

Robots in automated assembly use a Linear Displacement Sensor to verify arm positioning, gripper alignment, and component placement. The feedback provided by these sensors helps maintain high production rates without compromising precision.

For example, in automotive assembly, sensors ensure that components such as doors, windows, and seats are positioned and installed accurately.

Hydraulic and Pneumatic Systems

Hydraulic and pneumatic machinery relies on precise control of actuator positions for safe and efficient operation. A Linear Displacement Sensor measures the extension or retraction of hydraulic cylinders, allowing the system to control movement speed, limit positions, and ensure repeatability in repetitive processes.

Magnetostrictive sensors are often used in these systems because they are contactless, resistant to wear, and can operate in harsh environments with high pressure and vibration.

Presses and Stamping Machines

In metal forming, stamping, and pressing operations, a Linear Displacement Sensor ensures that the press stroke depth is consistent and within tolerance. This not only maintains product quality but also prevents damage to tooling and machinery by avoiding over-travel.

Packaging Machinery

In packaging applications, a Linear Displacement Sensor can be used to control conveyor systems, sealing mechanisms, and cutting devices. Accurate positioning is crucial to ensure that packages are cut, filled, and sealed correctly without wastage.

Optical or capacitive sensors are often employed here for their quick response times and ability to detect small positional changes.

Printing Machines

In industrial printing equipment, precise control over the print head’s movement is necessary to achieve high-quality, repeatable results. A Linear Displacement Sensor provides feedback on print head position, ensuring accurate alignment for each pass, even at high speeds.

Material Testing Equipment

In tensile, compression, and fatigue testing machines, a Linear Displacement Sensor measures the deformation of test specimens under load. This measurement helps determine the material’s mechanical properties, such as elasticity and strength.

LVDTs are common in testing environments due to their accuracy, stability, and ability to measure both small and large displacements.

Construction and Heavy Equipment

Linear Displacement Sensors are used in cranes, excavators, and other heavy machinery to monitor boom position, bucket tilt, and other movements. This improves operational safety, assists in automated positioning, and prevents overextension that could damage equipment.

Elevators and Lifts

In elevator systems, a Linear Displacement Sensor can track the cabin’s vertical position for smooth acceleration, deceleration, and stopping. This ensures passenger safety and comfort while minimizing mechanical wear.

Choosing the Right Linear Displacement Sensor for Machinery

When selecting a Linear Displacement Sensor for a machinery application, several factors must be considered:

Measurement Range: The sensor must cover the full travel distance of the moving part.

Resolution and Accuracy: Precision requirements vary by application; choose accordingly.

Environmental Conditions: Temperature, moisture, dust, and vibration resistance are critical in industrial environments.

Mounting and Size: The sensor should fit within available space without interfering with machinery operation.

Output Type: Select analog or digital outputs based on your control system compatibility.

Maintenance Requirements: Contactless sensors generally require less maintenance and have longer lifespans.

Maintenance and Care for Linear Displacement Sensors in Machinery

Keep the sensor and surrounding area clean from dust, oil, or debris.

Avoid overextending the sensor beyond its designed measurement range.

Periodically check mounting brackets and alignment.

Ensure that cables and connectors are secure and free from damage.

Follow the manufacturer’s calibration recommendations to maintain accuracy.

The Future of Linear Displacement Sensors in Machinery

As machinery becomes more advanced and connected through Industry 4.0 and IoT technologies, Linear Displacement Sensors are evolving to offer more than just position measurement.

Emerging trends include:

Wireless Connectivity: Reducing installation complexity and enabling remote monitoring.

Integrated Diagnostics: Detecting alignment issues, wear, or contamination.

AI-Based Data Analysis: Predicting maintenance needs based on movement patterns.

Miniaturization: Allowing integration into compact machinery and portable devices.

These advancements will expand the applications of Linear Displacement Sensors into even more areas of machinery, making them indispensable for future industrial operations.

FAQ

What is a Linear Displacement Sensor used for in machinery?

It measures the straight-line movement of machine components and converts that movement into an electrical signal for monitoring or control.

Can a Linear Displacement Sensor work in harsh industrial environments?

Yes, many are designed with rugged housings and sealing to resist dust, moisture, vibration, and temperature extremes.

Which type of Linear Displacement Sensor is best for CNC machines?

LVDTs and optical sensors are often preferred for CNC machines due to their high resolution and repeatability.

How do Linear Displacement Sensors improve machinery efficiency?

They provide real-time position feedback, allowing control systems to make quick adjustments, reducing errors, and improving process speed.

Are contactless Linear Displacement Sensors better than contact types?

Contactless sensors generally have longer lifespans and require less maintenance, but the choice depends on application needs.

Can a Linear Displacement Sensor be integrated with automation systems?

Yes, they can connect to PLCs, computers, and other control systems using analog or digital outputs.

How often should Linear Displacement Sensors be calibrated?

Calibration frequency depends on the application’s precision requirements and operating environment, but periodic checks are recommended.

Table of Contents

- Where to Use Linear Displacement Sensor in Machinery?

- Understanding the Linear Displacement Sensor

- Key Benefits of Using a Linear Displacement Sensor in Machinery

- Applications of Linear Displacement Sensors in Machinery

- Choosing the Right Linear Displacement Sensor for Machinery

- Maintenance and Care for Linear Displacement Sensors in Machinery

- The Future of Linear Displacement Sensors in Machinery

-

FAQ

- What is a Linear Displacement Sensor used for in machinery?

- Can a Linear Displacement Sensor work in harsh industrial environments?

- Which type of Linear Displacement Sensor is best for CNC machines?

- How do Linear Displacement Sensors improve machinery efficiency?

- Are contactless Linear Displacement Sensors better than contact types?

- Can a Linear Displacement Sensor be integrated with automation systems?

- How often should Linear Displacement Sensors be calibrated?