Can Linear Displacement Sensor Improve Precision Control?

In modern engineering, automation, and manufacturing industries, precision control is more than just a desirable feature — it’s an essential requirement. Whether it’s for robotics, aerospace, automotive production, or quality inspection systems, accuracy in measurement and control directly impacts product quality, operational efficiency, and safety. One of the most effective devices to achieve high levels of accuracy is the Linear Displacement Sensor.

By accurately measuring the movement or position of an object in a straight line, these sensors provide real-time feedback to control systems. This feedback allows for adjustments and corrections that enhance the precision of mechanical and electronic operations. In this article, we will explore what a Linear Displacement Sensor is, how it works, its applications, and why it plays a crucial role in improving precision control in various industries.

Understanding the Linear Displacement Sensor

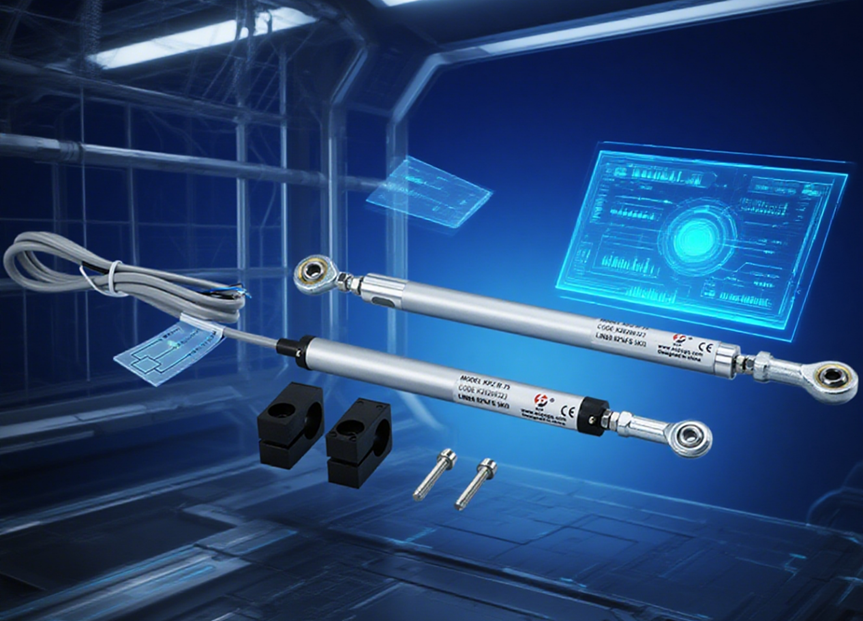

A Linear Displacement Sensor is a device that measures the linear movement of an object. It detects the amount of displacement — meaning how far an object has moved from a starting position — and converts this physical change into an electrical signal. This output can then be used by a control system to make necessary adjustments or record data for monitoring purposes.

There are different types of Linear Displacement Sensors, each suited to specific applications:

Potentiometric Sensors: Use a resistive track and a sliding contact to measure position.

Inductive Sensors: Use electromagnetic fields to detect movement without physical contact.

Capacitive Sensors: Measure changes in capacitance caused by movement.

Optical Sensors: Use light-based detection methods for high precision.

LVDTs (Linear Variable Differential Transformers): Use transformer technology for precise and robust measurements in harsh environments.

How a Linear Displacement Sensor Works

The working principle of a Linear Displacement Sensor depends on its type, but the general process is similar:

Movement Detection: The sensor identifies changes in the position of an object along a straight path.

Signal Conversion: The detected movement is transformed into an electrical signal, which can be voltage, current, or digital output.

Data Transmission: The signal is sent to a control unit, such as a PLC (Programmable Logic Controller) or computer.

Feedback and Control: The control system processes the signal, compares it to desired values, and makes necessary adjustments to maintain precision.

For example, in a CNC (Computer Numerical Control) machine, a Linear Displacement Sensor can continuously monitor the position of a cutting tool, ensuring the machine follows exact coordinates to create a part with minimal tolerance deviation.

Why Precision Control Matters

Precision control ensures that mechanical movements and operations are executed with minimal error. This is critical in industries where even a fraction of a millimeter can affect the functionality of the final product. High-precision control reduces waste, improves quality, and enhances overall productivity.

A Linear Displacement Sensor contributes to precision control by:

Providing continuous, real-time feedback.

Detecting micro-scale movements.

Enabling automation systems to self-correct instantly.

Applications of Linear Displacement Sensors in Precision Control

Robotics

In robotics, especially in automated assembly lines, the accuracy of movements determines how efficiently and reliably the robot performs tasks. A Linear Displacement Sensor ensures the robot arm moves exactly to the intended position.

Manufacturing and CNC Machines

CNC machines require precise positioning for cutting, drilling, and shaping materials. The feedback from a Linear Displacement Sensor helps maintain high accuracy even when environmental conditions, such as temperature, change during operation.

Aerospace Engineering

Aircraft components must meet extremely tight tolerances. Linear Displacement Sensors are used in the assembly process to monitor and control the alignment of parts.

Automotive Industry

From suspension testing to production line automation, Linear Displacement Sensors play a key role in ensuring components meet quality and safety standards.

Civil Engineering and Structural Monitoring

In construction and infrastructure maintenance, these sensors can measure structural movement or settlement, ensuring safety and compliance with engineering specifications.

Medical Devices

In medical equipment like MRI machines, surgical robots, or patient positioning systems, a Linear Displacement Sensor ensures movements are accurate and repeatable.

Advantages of Using a Linear Displacement Sensor for Precision Control

High Accuracy and Resolution

Modern Linear Displacement Sensors can detect minute changes in position, often down to micrometers.

Real-Time Monitoring

Instant feedback allows control systems to make immediate adjustments, reducing the risk of errors.

Durability in Harsh Environments

Many Linear Displacement Sensors are designed to withstand extreme temperatures, vibrations, and moisture.

Non-Contact Options

Some types, like optical and inductive sensors, do not require physical contact, reducing wear and maintenance needs.

Integration with Automation Systems

They can easily connect with PLCs, computers, and IoT systems for advanced monitoring and control.

Factors to Consider When Choosing a Linear Displacement Sensor

Measurement Range: The maximum distance the sensor can measure.

Resolution: The smallest detectable change in position.

Accuracy: How closely the measured value matches the actual position.

Environmental Conditions: Temperature, dust, humidity, and vibration resistance.

Output Type: Analog (voltage/current) or digital signals, depending on system requirements.

Mounting and Size: Physical compatibility with the equipment.

The Role of Linear Displacement Sensors in Automation

Automation relies heavily on sensors to provide the data necessary for precise control. In a smart manufacturing facility, Linear Displacement Sensors can be networked with other devices to create a synchronized, adaptive system. This means machines can detect slight deviations in position and correct them instantly, without stopping production.

For instance, in automated packaging lines, a Linear Displacement Sensor ensures that conveyor belts position products exactly before labeling or sealing, preventing misalignment and reducing waste.

Innovations in Linear Displacement Sensor Technology

Wireless Communication

Some modern sensors transmit data wirelessly, making them easier to install in moving or hard-to-reach components.

Miniaturization

Advances in manufacturing have led to smaller, lighter sensors that can be used in compact devices without sacrificing accuracy.

Self-Diagnostics

Newer sensors can detect faults in their own operation, alerting maintenance teams before errors cause downtime.

Integration with AI Systems

When combined with AI, a Linear Displacement Sensor can be part of predictive maintenance systems, identifying patterns that signal potential problems before they occur.

How Linear Displacement Sensors Improve Process Efficiency

By maintaining precise control, these sensors reduce production errors and material waste. They also allow for faster operation speeds without sacrificing accuracy, ultimately improving output and profitability.

For example, in 3D printing, the exact positioning of the print head is crucial for building accurate layers. A Linear Displacement Sensor provides the feedback needed for consistent results, even over long print times.

Challenges in Using Linear Displacement Sensors

While highly beneficial, there are some challenges:

Cost: High-precision models can be expensive.

Installation Complexity: Proper alignment and calibration are critical.

Environmental Interference: Dust, vibration, and temperature changes can affect accuracy if the sensor is not designed for those conditions.

The Future of Linear Displacement Sensors in Precision Control

As industries move toward greater automation and digitalization, demand for high-accuracy sensing will continue to grow. Future Linear Displacement Sensors are expected to:

Offer higher resolution and faster response times.

Integrate more deeply with IoT and AI systems.

Operate reliably in increasingly challenging environments.

Become more cost-effective as technology advances.

These trends will expand their use beyond traditional manufacturing into emerging fields like renewable energy, autonomous vehicles, and advanced robotics.

FAQ

What is a Linear Displacement Sensor used for?

It measures the straight-line movement of an object and converts it into an electrical signal for monitoring or control purposes.

How does a Linear Displacement Sensor improve precision control?

By providing real-time, accurate feedback on position, it allows control systems to make instant adjustments and maintain tight tolerances.

Which industries use Linear Displacement Sensors?

They are used in manufacturing, robotics, aerospace, automotive, civil engineering, and medical device production.

Are Linear Displacement Sensors always contact-based?

No. While some types require physical contact, others like optical and inductive sensors measure displacement without touching the target.

What is the difference between accuracy and resolution in these sensors?

Accuracy refers to how close the measurement is to the actual value, while resolution refers to the smallest detectable change in position.

Can Linear Displacement Sensors work in harsh environments?

Yes, many models are designed to resist dust, moisture, extreme temperatures, and vibration.

Do they require frequent maintenance?

Most have low maintenance needs, especially non-contact models, but periodic calibration may be necessary for optimal accuracy.

Table of Contents

- Can Linear Displacement Sensor Improve Precision Control?

- Understanding the Linear Displacement Sensor

- How a Linear Displacement Sensor Works

- Why Precision Control Matters

- Applications of Linear Displacement Sensors in Precision Control

- Advantages of Using a Linear Displacement Sensor for Precision Control

- Factors to Consider When Choosing a Linear Displacement Sensor

- The Role of Linear Displacement Sensors in Automation

- Innovations in Linear Displacement Sensor Technology

- How Linear Displacement Sensors Improve Process Efficiency

- Challenges in Using Linear Displacement Sensors

- The Future of Linear Displacement Sensors in Precision Control

-

FAQ

- What is a Linear Displacement Sensor used for?

- How does a Linear Displacement Sensor improve precision control?

- Which industries use Linear Displacement Sensors?

- Are Linear Displacement Sensors always contact-based?

- What is the difference between accuracy and resolution in these sensors?

- Can Linear Displacement Sensors work in harsh environments?

- Do they require frequent maintenance?