Let’s talk about how shear beam load cells are really changing the game when it comes to industrial efficiency. In today’s fast-paced world of industrial tech, accuracy and dependability are more important than ever. And honestly, shear beam load cells are one of those technologies that have really proven their worth over the years, showing up in all sorts of applications. As companies look for ways to get more precise with their weight measurements and streamline operations, these load cells are becoming pretty much essential.

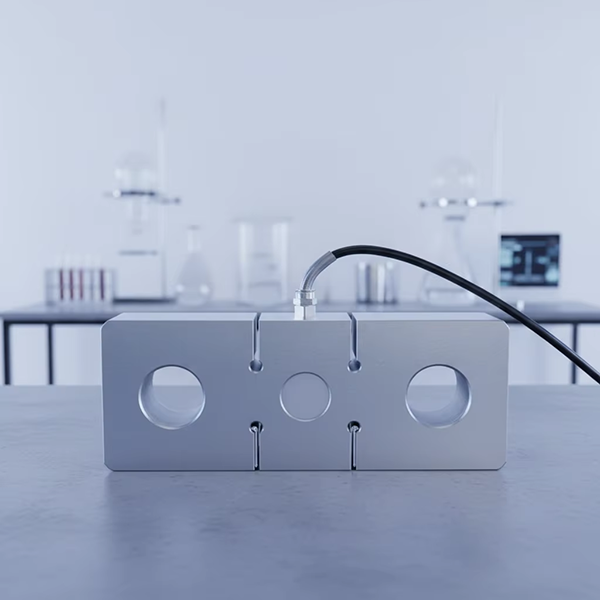

So, what exactly are shear beam load cells? Well, at their core, they’re devices that turn force into an electrical signal—think of them as the brains behind a measurement system. They use what’s called the shear strain principle, which makes them super reliable for tasks that need high precision. Unlike other load cells, shear beams are built tough—they’re designed to handle heavy shear forces, so they can survive in pretty harsh environments without breaking a sweat.

You’ll see these load cells popping up all over different industries. From manufacturing lines and shipping yards to construction sites and farms, they play a big role in making sure everything runs smoothly. For example, on weighbridge trucks or large platform scales, shear beam load cells help ensure the weights are accurate—crucial for billing, safety, and regulatory compliance.

And in agriculture? They help farmers keep track of grains stored in silos, so they can better manage their stocks. In factories, they’re used to automate processes, which means higher productivity and less waste. Even the car industry benefits from these load cells—used in things like suspension testing and weighing vehicles, where precision really matters.

What makes shear beam load cells stand out? For starters, they’re pretty good at keeping their accuracy even when there are vibrations, temperature swings, or rough handling. Their compact size means they fit easily into existing setups, saving space and money. Plus, recent advances in materials—like stainless steel and aluminum—have made them last longer and cut down on maintenance costs.

Bottom line: As industries grow and evolve, the need for trustworthy measurement tools gets even more critical. Shear beam load cells really showcase engineering at its best—combining reliability with durability. For any business wanting to step up its game and stay competitive, investing in these load cells is a smart move. With ongoing technology improvements, we’re likely to see these devices become even more vital, helping make industries smarter and more efficient than ever before.