torque sensor manufacturers

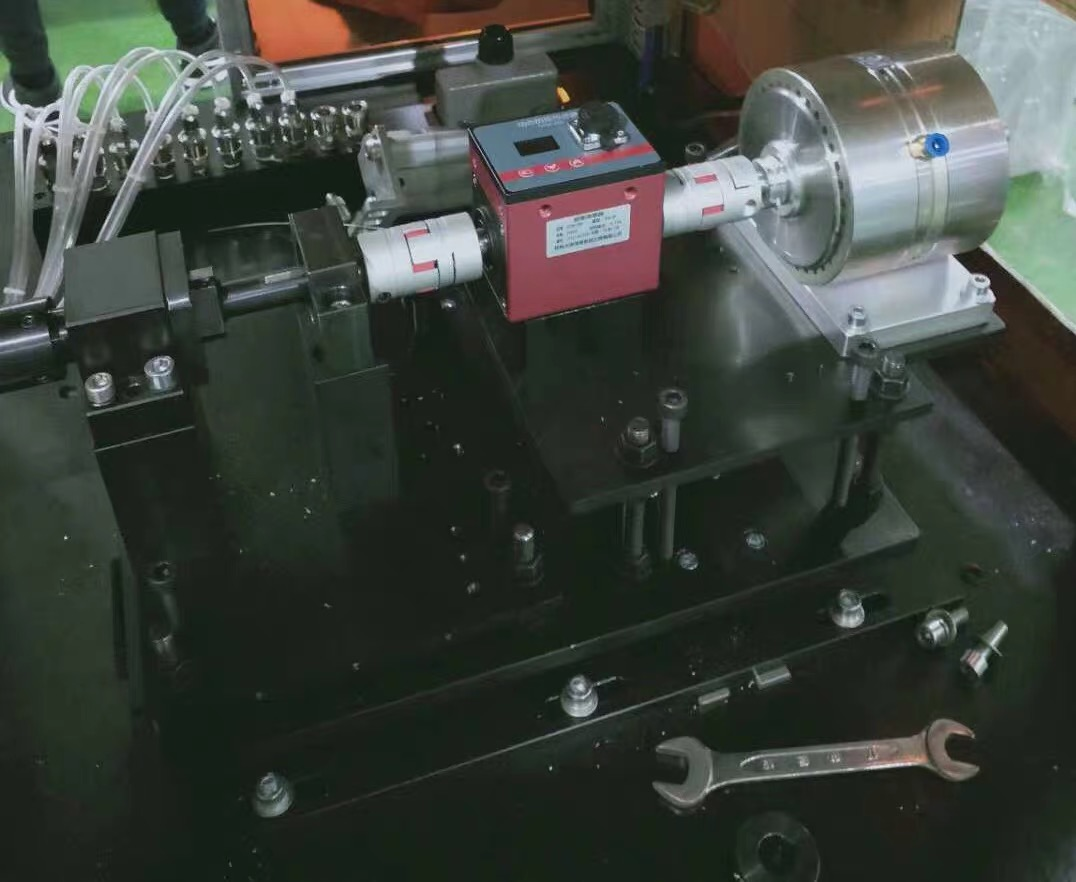

Torque sensor manufacturers play a crucial role in the industrial automation and measurement industry, specializing in the development and production of high-precision torque measurement devices. These manufacturers leverage advanced engineering capabilities to create sensors that accurately measure rotational force in various applications. Their product lines typically encompass both static and dynamic torque measurement solutions, catering to diverse industry needs. Leading manufacturers incorporate cutting-edge technologies such as strain gauge systems, magnetoelastic principles, and digital signal processing to ensure precise measurements. These companies maintain strict quality control processes throughout the manufacturing cycle, from material selection to final testing. Many manufacturers offer customization options to meet specific application requirements, including different measurement ranges, interface options, and environmental protection levels. Their facilities are equipped with state-of-the-art calibration equipment and testing laboratories to ensure product reliability and accuracy. Additionally, these manufacturers often provide comprehensive technical support, including installation guidance, maintenance services, and calibration certification to ensure optimal sensor performance throughout its lifecycle.