torque sensor buy

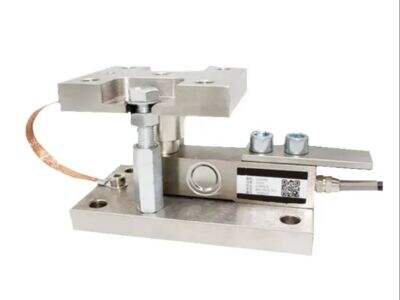

A torque sensor buy represents a crucial investment in precision measurement technology, offering sophisticated capabilities for monitoring and measuring rotational force in various mechanical systems. These advanced devices incorporate state-of-the-art strain gauge technology, providing real-time measurements with exceptional accuracy levels of up to 0.1%. Modern torque sensors feature digital outputs compatible with industry-standard protocols, enabling seamless integration with existing control systems and data acquisition equipment. The sensors come equipped with temperature compensation mechanisms, ensuring reliable measurements across diverse operating conditions. They support both static and dynamic torque measurements, making them versatile tools for quality control, research and development, and production environments. The purchase includes comprehensive calibration certificates, ensuring traceability to international standards. These sensors are designed with robust housings, typically featuring IP65 or higher protection ratings, guaranteeing reliable operation in challenging industrial environments. The integration capabilities extend to various communication protocols, including USB, CAN, and Ethernet, facilitating easy data collection and analysis. Advanced models often include built-in overload protection and diagnostic features, protecting your investment and ensuring long-term reliability.