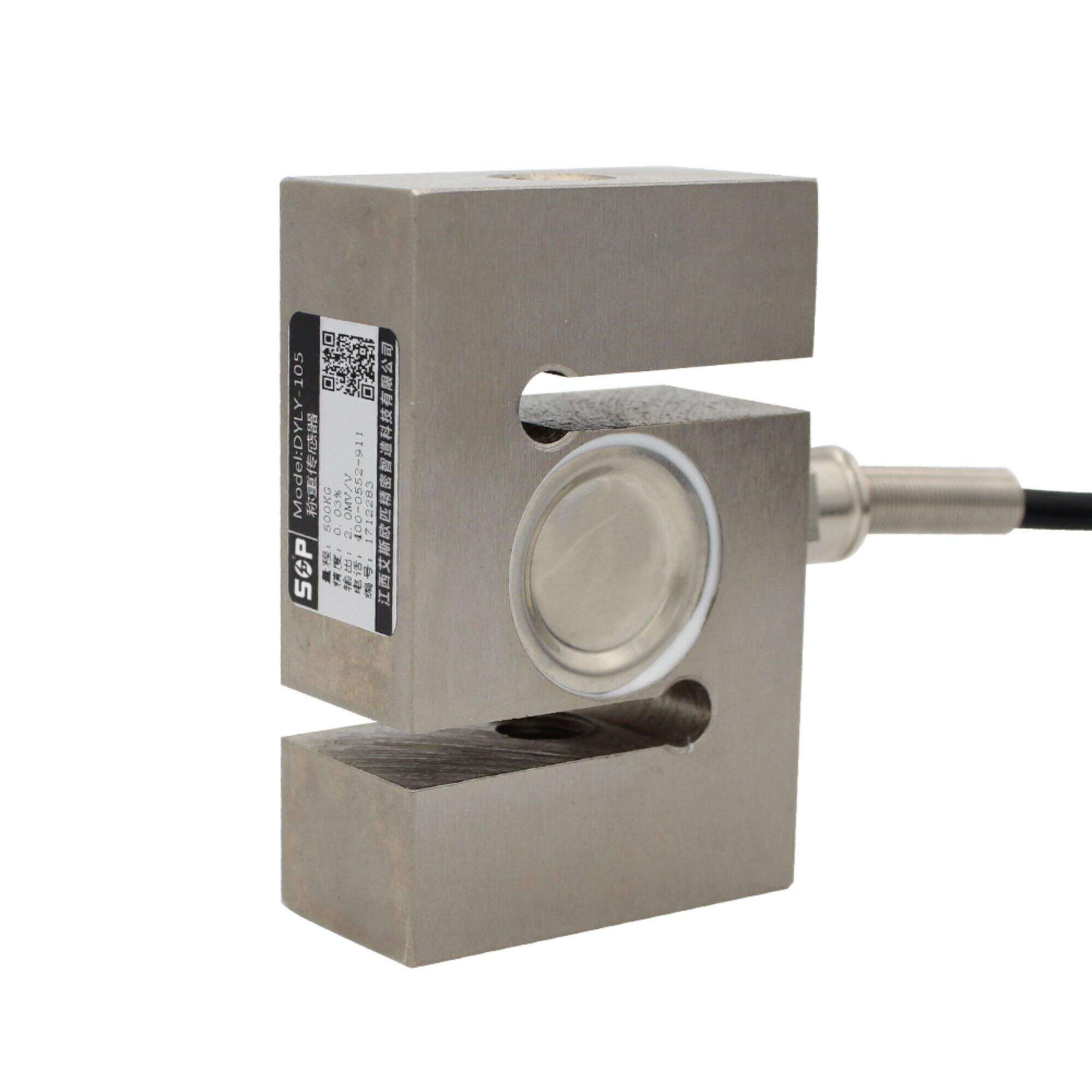

Have you ever stopped to think how we weigh things of this heavy? Simple process, but we have this handy tool used to do it for us. This is a shear type load cell A shear type load cell is a little tool that we utilize to recognize just how heavy something remains in situation when put on top of it. Sometimes, it is used in factories and other places where precision weight measurements are necessary.

The working principle of a shear type load cell is also very simple. It has a custom analog load cell that is activated by pushing down on the weight of something heavy, for example product or equipment [8]. The most important sensor is the one that counts and this measures weight. The sensor bends slightly when the item presses down. The fact that the object is bending tells us in essence there it has mass, and with all acceleration experiments everything boils down to force. The harder the force, the more it bent and created a stronger electrical signal.

Factory work is a great deal easier than it has ever been with shearing type load cell. However, one nice benefit is that it is very precise. Load cells of shear type are able to carry out quite precise measurements on weight. In a factory, where exact measurements are essential for safety and quality control this precision is crucial. A load cell with a defect will produce inaccurate measurements which may result in downstream production issues.

Shear type load cells are extremely robust and will outlive most other forms of cell. These are built to handle a lot, and can even perform under harsh conditions such as in factories. The design of these load cells in such a way that they are not easily damaged by rust, bumps or changes in temperature from extreme heat to severe cold. This means they are also rugged enough for operation in demanding surroundings.

Picking the right shear type load cell is crucial or whatever you want. First, consider what weight you are will be measuring. There are different weight attributes of shear type load cells that you also want to consider in purchasing one as it can only weigh certain amount of objects. In case your load cell is not built to fit a particular weight, then the sensor might likely crack or display inaccurate measurements.

Although shear type load cells are amazing for measurement, at times they will provide the wrong numbers. There are several common mistakes which can occur when you might put too much weight on the load cell, mis-align it or use an incorrect load-cell for your application. As decades pass, it can be worn down or otherwise damaged such that you lose the ability to use this machine correctly if you put too much weight on it.

Lining it up wrong, or damaging will also give inaccurate measurements. Before using the load cell, it is essential to ensure that its device-specific input/output structure has been configured correctly. This is to make sure it's straight and well attached. When you weight a load cell that it cannot support the results may also be poor. Check the weight capacity before you start

We provide a broad range of products include linear displacement sensors drawn wire sensors, LVDT sensors, load cells torque sensors, pressure sensors, shear type load cell sensors, more. We offer OEM/ODM support per the specifications of the customer.

SOP is a high-tech manufacturer has over 20 years of shear type load cell production and worked with more than 5000 customers around world. It is a well-established company engaged research, development and production of different types of sensors.

Customers have option choosing from range of transportation services. We provide safe packaging expedited shipping all items in stock. You will receive shear type load cell details once the product is shipped.

We are accredited by CE, RoHS ISO9001. We ensure every item undergoes a rigorous inspection prior shear type load cell. SOP also has engineers can offer after-sales services solve any problems with the product.