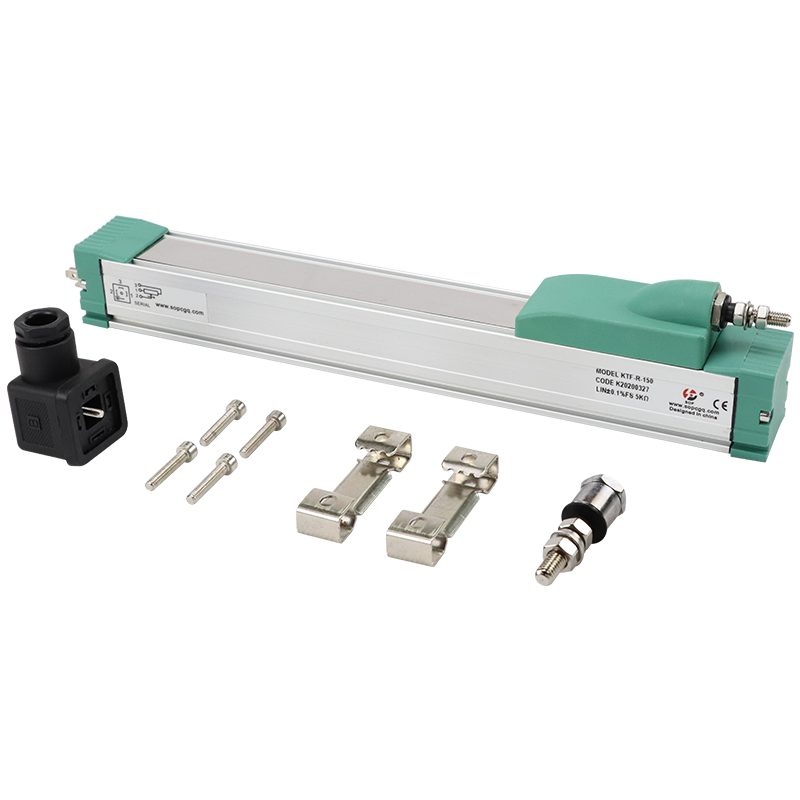

non contact linear position sensor

A non contact linear position sensor represents a sophisticated measurement device that determines an object's linear position without physical contact. This innovative technology utilizes various principles such as magnetic fields, optical systems, or capacitive sensing to accurately track position changes. The sensor consists of a sensing element and a target, maintaining a precise gap between them to ensure accurate measurements. These sensors operate by detecting changes in magnetic flux, light intensity, or capacitance, converting these variations into electrical signals that correspond to position data. With measurement ranges from a few millimeters to several meters, they offer exceptional precision and reliability in diverse industrial applications. Their functionality extends to harsh environments where traditional contact-based sensors might fail, providing continuous position feedback without mechanical wear. The technology incorporates advanced signal processing capabilities, ensuring high-resolution measurements and minimal interference from external factors. These sensors often feature built-in temperature compensation and electromagnetic interference protection, maintaining accuracy across varying operating conditions. They find extensive use in automation systems, robotics, automotive applications, and precision manufacturing, where accurate position measurement is crucial for process control and quality assurance.