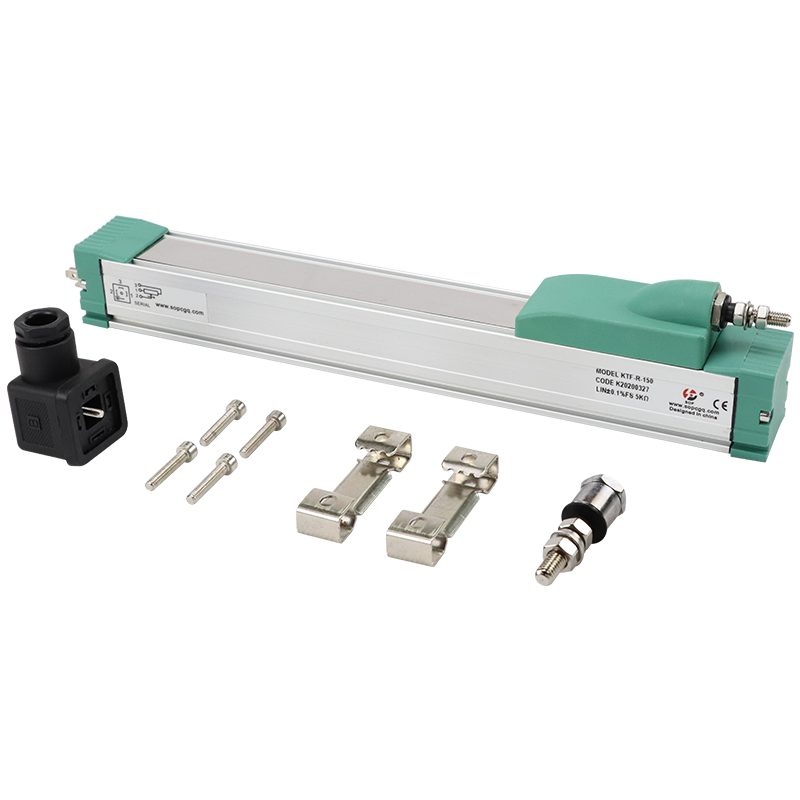

lvdt sensor manufacturer

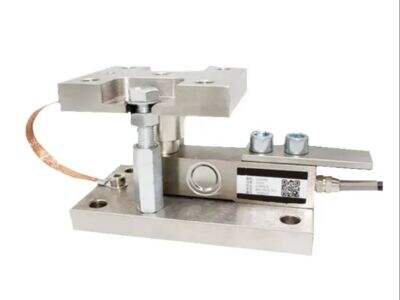

An LVDT sensor manufacturer specializes in designing, producing, and distributing Linear Variable Differential Transformer sensors, which are essential components in modern industrial automation and measurement systems. These manufacturers combine precision engineering with advanced manufacturing processes to create highly accurate position measurement devices. Their production facilities typically feature state-of-the-art equipment and rigorous quality control measures to ensure consistent product performance. The manufacturing process involves careful assembly of core components, including the primary and secondary coils, the magnetic core, and protective housing. These manufacturers often provide customization options to meet specific application requirements, offering various stroke lengths, output signals, and environmental protection ratings. They maintain strict adherence to international standards such as ISO 9001 and industry-specific certifications, ensuring their products meet global quality benchmarks. Most LVDT sensor manufacturers also offer comprehensive technical support, including calibration services, installation guidance, and maintenance assistance. Their expertise extends to developing specialized solutions for challenging environments, such as high-temperature applications, underwater operations, or areas with strong electromagnetic interference.