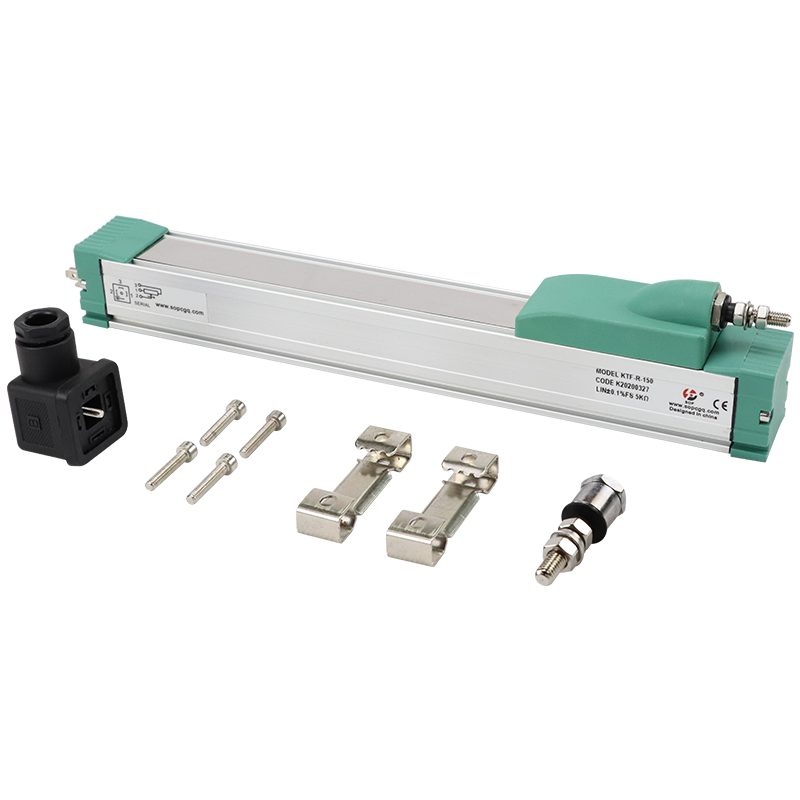

customized lvdt sensor

A customized LVDT (Linear Variable Differential Transformer) sensor represents a sophisticated measurement solution engineered to deliver precise linear displacement measurements in diverse industrial applications. These sensors operate on electromagnetic principles, utilizing primary and secondary coils to convert mechanical movement into electrical signals with exceptional accuracy. The customization aspect allows for specific adaptations in stroke length, housing materials, output signals, and environmental protection to meet unique application requirements. Modern customized LVDT sensors incorporate advanced features such as digital signal processing, temperature compensation, and various output options including analog, digital, or wireless transmission capabilities. Their robust design ensures reliable operation in challenging environments, with many models offering resistance to extreme temperatures, pressure, and corrosive substances. These sensors excel in applications requiring high-precision measurements, such as automated manufacturing systems, aerospace testing equipment, hydraulic systems, and quality control processes. The integration capabilities of customized LVDT sensors with modern control systems make them invaluable in Industry 4.0 applications, where real-time monitoring and precise control are essential. Their non-contact measuring principle ensures minimal mechanical wear, contributing to extended operational life and maintenance-free performance.