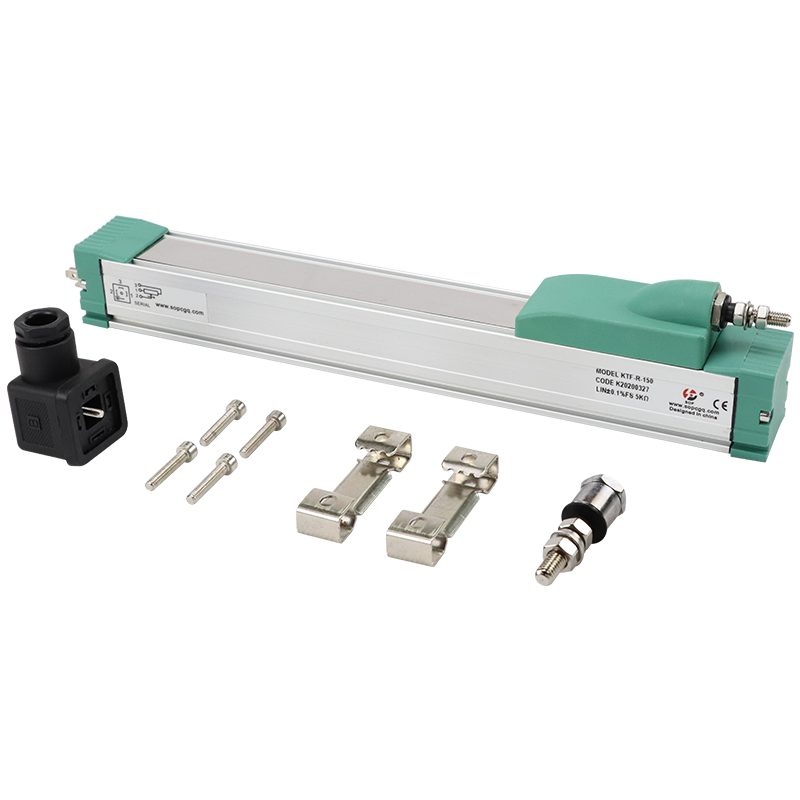

customized linear position transducer types

Customized linear position transducers represent advanced sensing technology designed to precisely measure linear displacement in various industrial applications. These sophisticated devices convert linear motion into electrical signals, providing accurate position feedback essential for automation and control systems. The technology incorporates multiple sensing principles, including magnetostrictive, potentiometric, and LVDT (Linear Variable Differential Transformer) mechanisms, each tailored to specific application requirements. Modern customized linear position transducers feature robust construction with high-grade materials, ensuring durability in demanding industrial environments. They offer exceptional accuracy levels, typically ranging from ±0.05% to 0.1% of full scale, making them ideal for precision-critical applications. The devices support various output signals, including analog (4-20mA, 0-10V) and digital interfaces (SSI, CANbus), enabling seamless integration with modern control systems. These transducers find extensive applications in hydraulic systems, material handling equipment, industrial automation, aerospace, and automotive testing platforms, where reliable position feedback is crucial for operational efficiency and safety.