Ever wonder how we know how much stuff weighs? Have you ever seen a truck being weighed at one of the weigh stations and pondered how in world does that scale work? It’s really interesting! Weighing of truck is done with a special device called canister type load cell. It helps us understand how heavy something is, and it used in many places.

How to use and install a canister type load cell ACanistertype_Loadcell You may think of it as a little friend that helps us know how heavy objects are. It is frequently used in the weighing of heavy vehicles, production lines where stationary scales are installed, large tanks and hoppers for dry bulk materials. The load cell operates by squeezing a steel cylinder that is inside it. This cylinder squishes down when a heavy object is placed on it. The squishing action is detected by a computer to let it know how heavy the object being weighed is. Therefore, the next time you watch something heavy get weighed more than likely it was carried out by a canister type load cell!

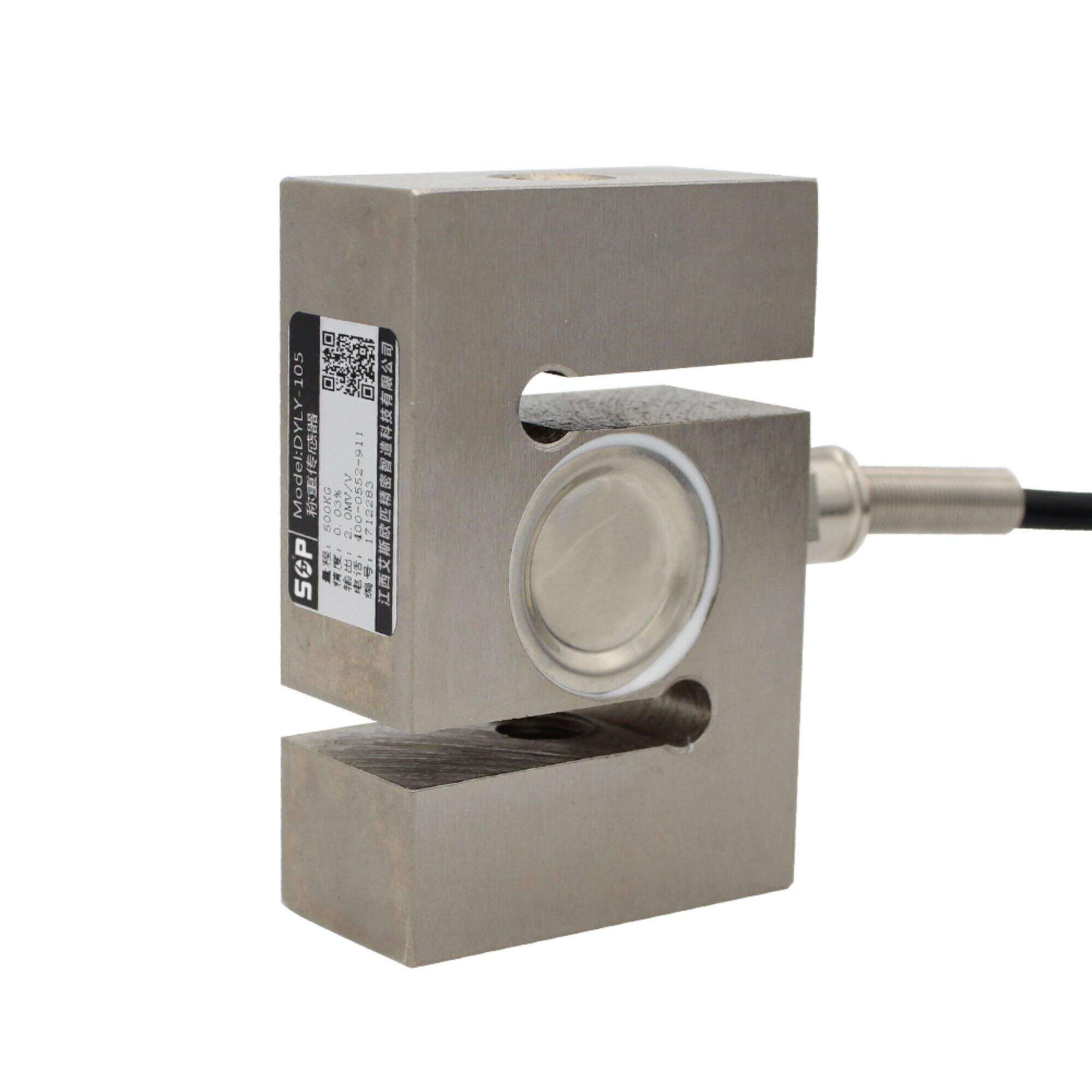

The canister type load cells using the strain gauge technology. This is to say they can gauge changes that result from squeezing (adding weight, for instance), which causes their term High-resolution pressure-sensitive__. This type contains a four stress gauges in it, called as load cell canister. Two of the gauges measure downward pushing on cylinder and another two will be measuring pulling force. The way they deform allows us to calculate the weight of whatever object is resting on top of that load cell. Every time something gets weighed, it's like a little science experiment going on!

It is indeed very useful and beneficial to weigh things using a canister type load cell. That is the fact that they are accurate. On automatic scales the weight is read as soon and almost to a fraction of milligram, e. g in kg - 0. They Are Ideal For Weighing Very Heavy Objects Even the canister type load cells are pretty durable and will be lasting longer which makes them an excellent consideration for weighing heavy items on a regular basis. So commonly used in various industries to weigh things, because of its reliable services.

There are some essential things which you need to consider when choosing a canister type load cell for your requirements. First thing is first, check the weigh capacity. Be certain the load cell can support whatever you will be weighing, so not surprises there. Next, look for accuracy. You will need a load cell that consistently produces accurate measurements. The trick is ensuring the true weight of whatever object you purchase. Live-area: Also, make sure that you buy the one which is easy to be set up and very hard in nature so it survives also on daily basis usage without any breakage.

Contact us if you are facing a problems connected to this Load cellsOr To get in touch with these type load cell_Application_supportBlue_Robotics0 - 50.

The canister type load cells for sure are great tools but there can be certain problems that may occur. However, amongst those faults is a broken wire. If a wire breaks, the signal will no longer be sent to the computer and numbers displayed on screen are not correct. The problem can also come from a bad connection. They can make mistakes if the connection is not very interested in gratifying these weights (which would mean an even longer wait for dinner?). The load cell is sometimes over or improperly used, and could become damaged. If it does, replace the relay in order for this to work correctly.

Our main products comprise various kinds of sensors, such as linear displacement sensor, draw wire sensor, load cell, LVDT sensor torque sensor, pressure sensor, magneto sensor more. We provide OEM/ODM services accordance with canister type load cell of the customer.

Customers canister type load cell from variety of transport options. We provide safe packaging speedy delivery all our stock items. You will receive tracking details following the delivery your goods.

SOP has over 20 years production experience has worked with more 5000 global customers, which is canister type load cell company manufactures high-tech products and is involved in research, development and production, as well as sale and servicing of various kinds of sensors.

Our company been accredited by CE, RoHS, ISO9001 well as other certifications. Before shipment, we examine each product. SOP also provides engineers offer after-sales canister type load cell solve any problems with product.