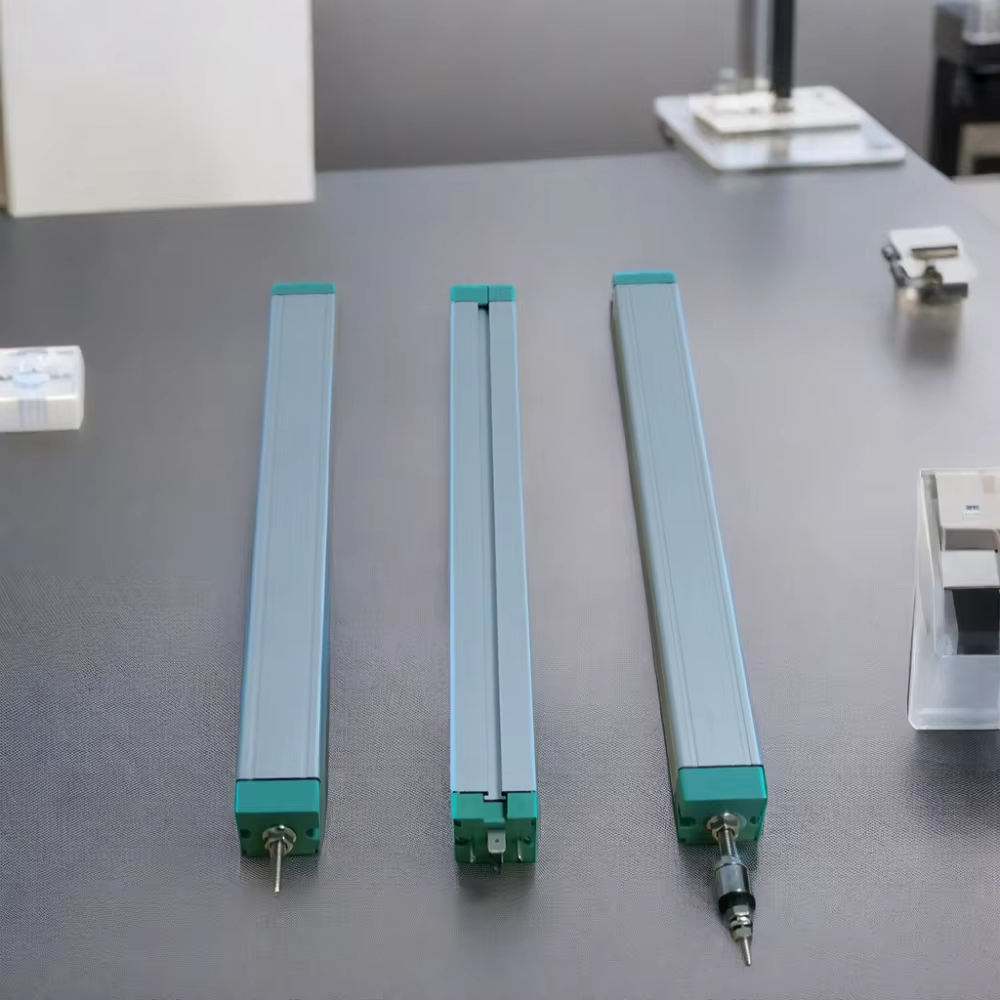

bộ chuyển đổi trọng lượng

Một bộ chuyển đổi trọng lượng là thiết bị điện tử tiên tiến có chức năng chuyển đổi các phép đo lực cơ học thành tín hiệu số chính xác, đóng vai trò thiết yếu trong các hệ thống cân công nghiệp hiện đại. Những thiết bị tinh vi này tích hợp liền mạch với cảm biến lực (load cell) để cung cấp các phép đo trọng lượng chính xác trong nhiều ứng dụng khác nhau. Thiết bị xử lý tín hiệu thô từ các cảm biến lực, áp dụng các hệ số hiệu chuẩn và thuật toán lọc để đảm bảo kết quả đo trọng lượng cực kỳ chính xác. Các bộ chuyển đổi trọng lượng hiện đại được trang bị khả năng chuyển đổi tương tự - số độ phân giải cao, hỗ trợ nhiều giao thức truyền thông bao gồm Modbus TCP, Ethernet IP và Profibus, cùng các chức năng chẩn đoán nâng cao để giám sát hệ thống. Chúng hỗ trợ nhiều loại tín hiệu đầu vào khác nhau và có thể kết nối đồng thời với nhiều cảm biến lực, mang lại tính linh hoạt cho cả các ứng dụng cân đơn giản và phức tạp. Khả năng xử lý của bộ chuyển đổi bao gồm theo dõi điểm không tự động, lọc tín hiệu số và bù nhiệt độ, đảm bảo kết quả đo đáng tin cậy ngay cả trong điều kiện môi trường thay đổi. Thông thường, các thiết bị này được trang bị giao diện thân thiện với người dùng cùng màn hình LCD để giám sát và cấu hình tại chỗ, đồng thời cung cấp nhiều tùy chọn kết nối để tích hợp với các hệ thống điều khiển và nền tảng quản lý dữ liệu quy mô lớn hơn. Bộ chuyển đổi trọng lượng được ứng dụng thiết yếu trong tự động hóa quy trình sản xuất, quản lý kho bãi, vận hành phối trộn nguyên liệu và kiểm soát chất lượng tại các ngành công nghiệp như thực phẩm - đồ uống, sản xuất dược phẩm và xử lý hóa chất.