ผู้ผลิตเซนเซอร์ตำแหน่งเชิงเส้น

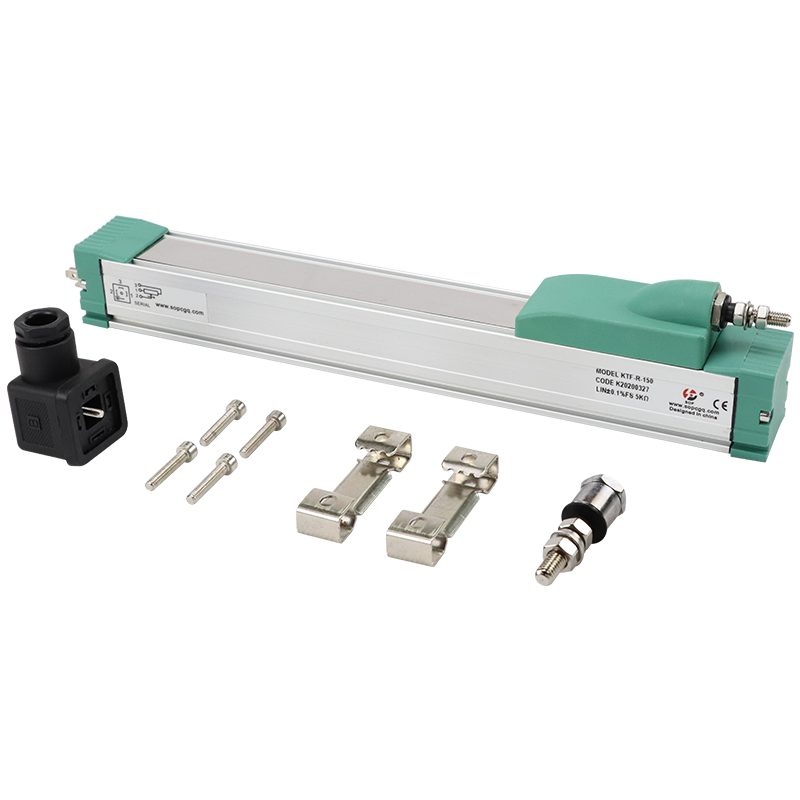

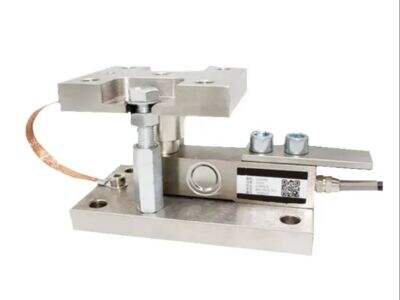

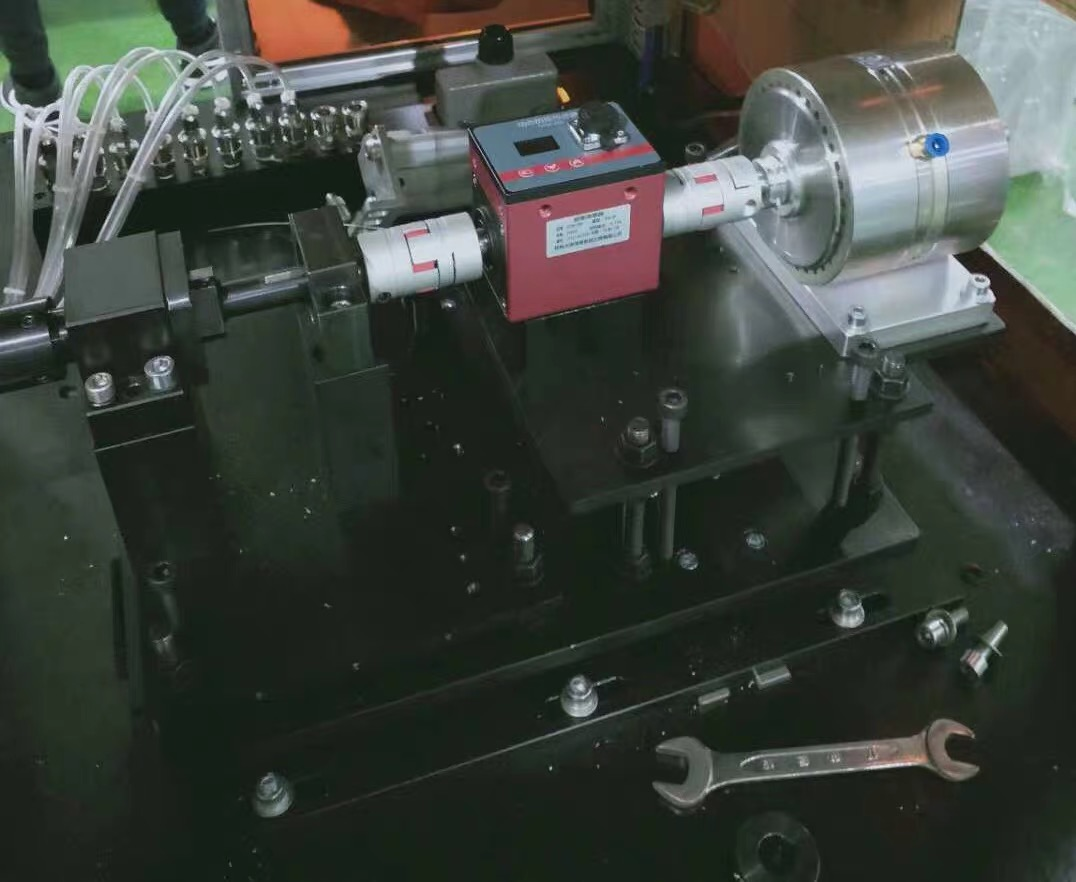

ผู้ผลิตเซ็นเซอร์วัดตำแหน่งเชิงเส้นมีความเชี่ยวชาญในการออกแบบและผลิตอุปกรณ์ที่มีความแม่นยำสูง ซึ่งสามารถวัดการเคลื่อนที่เชิงเส้นและการบอกตำแหน่งได้อย่างถูกต้องในหลากหลายการใช้งานอุตสาหกรรม เหล่าผู้ผลิตเหล่านี้นำความชำนาญทางด้านวิศวกรรมขั้นสูงมาผสมผสานกับโรงงานผลิตที่ทันสมัย เพื่อสร้างสรรค์เซ็นเซอร์ที่ให้ความแม่นยำ ความน่าเชื่อถือ และความทนทานระดับยอดเยี่ยม โดยทั่วไปแล้ว ผลิตภัณฑ์ของพวกเขาจะประกอบด้วยเทคโนโลยีเซ็นเซอร์แบบสัมผัส (contact) และแบบไม่สัมผัส (non-contact) ที่ทำงานบนหลักการตรวจจับแบบแม่เหล็กยืด (magnetostrictive) แบบโพเทนชิโอมิเตอร์ (potentiometric) และแบบแสง (optical) เซ็นเซอร์เหล่านี้ถูกออกแบบมาเพื่อให้ทำงานได้อย่างสม่ำเสมอภายใต้สภาพแวดล้อมที่ท้าทาย มีโครงสร้างแข็งแรงทนทานต่ออุณหภูมิสุดขั้ว การสั่นสะเทือน และสภาพการทำงานที่หนักหน่วง กระบวนการผลิตมีการควบคุมคุณภาพอย่างเข้มงวด เพื่อให้แน่ใจว่าเซ็นเซอร์แต่ละตัวตรงตามข้อกำหนดด้านประสิทธิภาพที่เคร่งครัดและมาตรฐานสากล ผู้ผลิตเซ็นเซอร์วัดตำแหน่งเชิงเส้นในยุคปัจจุบันเน้นนวัตกรรมผ่านการวิจัยและพัฒนาอย่างต่อเนื่อง ส่งผลให้ความสามารถของเซ็นเซอร์ดีขึ้น ขนาดเล็กลง และมีการผนวกฟีเจอร์อัจฉริยะ เช่น ขาออกสัญญาณดิจิทัลและการเชื่อมต่อ IoT อุตสาหกรรมที่บริษัทเหล่านี้ให้บริการมีความหลากหลาย ได้แก่ ยานยนต์ อากาศยาน อุตสาหกรรมระบบอัตโนมัติ และอุปกรณ์ทางการแพทย์ พร้อมทั้งเสนอทางแก้ไขเฉพาะที่ตรงตามความต้องการเฉพาะของการใช้งาน แนวทางการทำงานแบบรอบด้านของพวกเขารวมถึงการสนับสนุนทางเทคนิค การออกแบบพิเศษ และการช่วยเหลือหลังการขาย เพื่อให้แน่ใจว่าเซ็นเซอร์ทำงานได้อย่างเหมาะสมตลอดอายุการใช้งาน