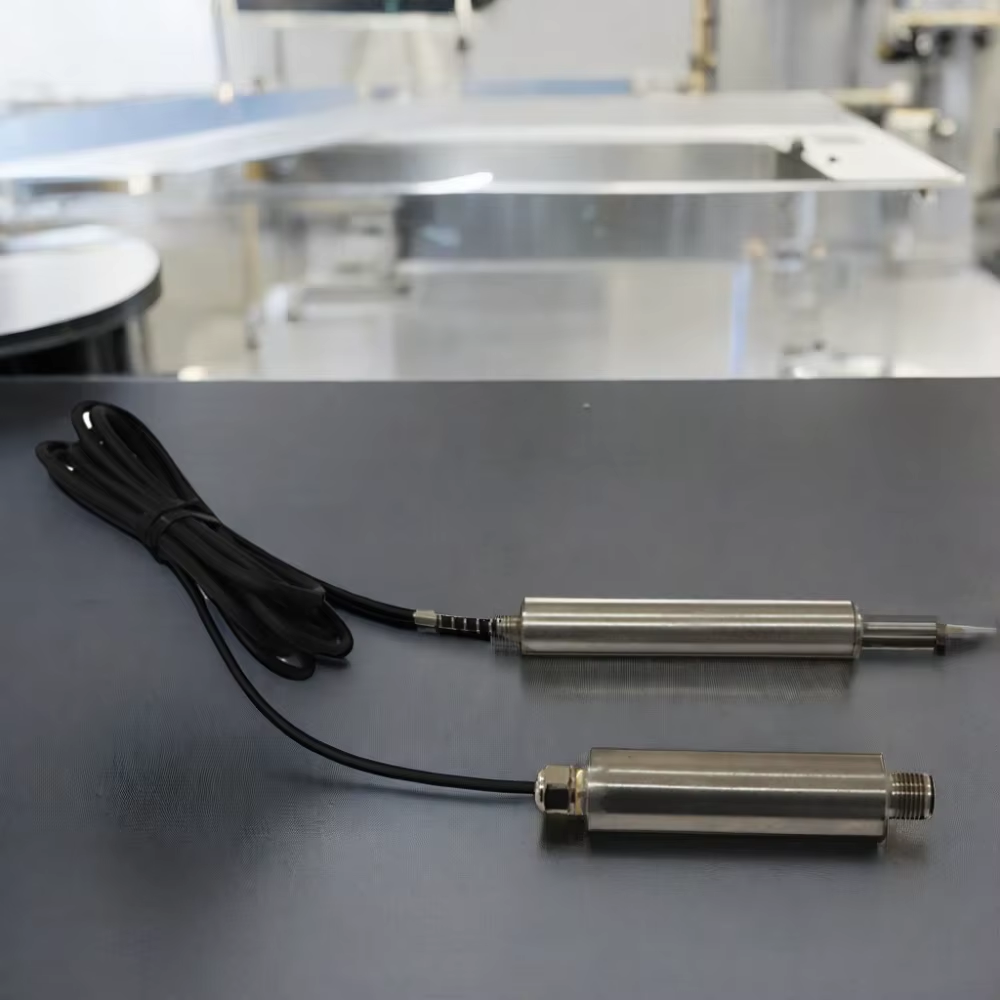

induktiv närhetssensor

En induktiv närvarosensor är en sofistikerad elektronisk anordning som upptäcker förekomsten av metallföremål utan fysisk kontakt. Dessa sensorer fungerar efter elektromagnetiska principer och genererar ett högfrekvent elektromagnetiskt fält som förändras när metallföremål kommer inom deras detekteringsområde. Sensorns oscillator skapar ett elektromagnetiskt fält från dess sensoryta, och när ett metallmål kommer in i detta fält induceras virvelströmmar i målet, vilket leder till energiförluster i sensorns oscillator krets. Denna förändring utlöser sensorns utgång att växla mellan tillstånd, vilket indikerar närvaron av metallföremålet. Dessa sensorer är kända för sin exceptionella hållbarhet, hög hastighet i drift och tillförlitlig prestanda i hårda industriella miljöer. De kan fungera effektivt genom smuts, damm och andra icke-metalliska material, vilket gör dem idealiska för olika industriella applikationer. Detekteringsavståndet varierar beroende på sensors storlek och målmaterial, där större sensorer vanligtvis erbjuder längre detekteringsavstånd. Moderna induktiva närvarosensorer innehåller ofta funktioner såsom LED-statusindikatorer, justerbara känslighetsinställningar och olika utgångskonfigurationer för att passa olika styrsystem. De spelar en avgörande roll i tillverkningsprocesser, automationssystem och kvalitetskontrollapplikationer, där de säkerställer exakt och konsekvent objektdetektering.