Датчик нагрузки: Революционное устройство для точного измерения веса

Введение в датчики нагрузки

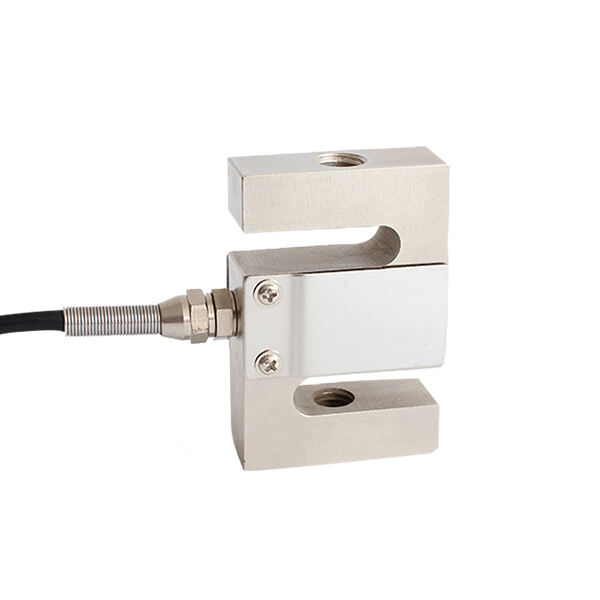

Датчик веса, также известный как датчик нагрузки, это высокоинновационное устройство для измерения веса. SOP датчиковая нагрузка работает как преобразователь, который преобразует приложенную силу в электрический сигнал, а затем передает его на электронное устройство, например, компьютер и другие. Статья сосредотачивается на преимуществах, инновациях, мерах безопасности и использовании датчиков нагрузки.

У датчиков нагрузки есть несколько преимуществ. Одним из основных преимуществ является их высокая точность. Они точно измеряют веса, что делает их подходящими для различных применений, таких как промышленное взвешивание, взвешивание грузов и т.д. Другое преимущество — это простота использования с типом SOP тип нагрузки . Вы можете использовать их много раз без какой-либо подготовки, что делает их идеальными как для профессионального, так и для потребительского использования. Кроме того, они могут выдерживать суровые условия окружающей среды, поэтому очень долговечны.

У датчиков нагрузки есть несколько преимуществ. Одним из основных преимуществ является их высокая точность. Они точно измеряют веса, что делает их подходящими для различных применений, таких как промышленное взвешивание, взвешивание грузов и т.д. Другое преимущество — это простота использования с типом SOP тип нагрузки . Вы можете использовать их много раз без какой-либо подготовки, что делает их идеальными как для профессионального, так и для потребительского использования. Кроме того, они могут выдерживать суровые условия окружающей среды, поэтому очень долговечны.

За последние несколько лет в технологии датчиков нагрузки произошло много улучшений. Современные датчики нагрузки точнее, меньше и универсальнее, чем когда-либо раньше. Одно из значительных инноваций в этой области — беспроводная связь. Современный SOP сенсор нагрузки имеет возможности беспроводной передачи данных напрямую на другие устройства, включая компьютеры, планшеты и смартфоны. Улучшилась точность, повысилась производительность, чувствительность, появились более простые варианты калибровки и меры компенсации ошибок, а также прочное строение.

Несмотря на то, что при использовании датчиков нагрузки нужно соблюдать некоторые предосторожности, большинство из них безопасны для использования широкой общественностью. Во-первых, пользователь должен использовать их только по назначению, для которого они были разработаны. Любое другое применение может привести к повреждению устройства и травмам. Второй важный момент связан с калибровкой. SOP дАТЧИК НАГРУЗКИ следует правильно откалибровать перед использованием. Это обеспечивает точные показания и предотвращает дорогостоящий ремонт.

За более чем 20 лет опыта в производстве и сотрудничества с более чем 500 клиентами по всему миру, SOP является уважаемой компанией, производящей высокотехнологичные продукты, а также занимающейся исследованием, разработкой, производством, продажей和服务 различных видов датчиков.

Мы предлагаем широкий ассортимент продукции, включая линейные дисплейсмент-датчики, датчики проводного типа, датчики LVDT, датчики нагрузки, датчики крутящего момента, датчики давления, датчики нагрузки и другие. Мы предоставляем поддержку OEM/ODM согласно спецификациям клиента.

Клиенты могут выбрать датчик нагрузки из различных вариантов доставки. Мы обеспечиваем безопасную упаковку и быструю доставку всех наших товаров со склада. Вы получите информацию о трекинге после отправки вашего груза.

Мы сертифицированы CE, RoHS ISO9001. Перед отгрузкой проверяем каждый продукт. Инженеры датчиков нагрузки SOP также предоставляют послепродажное обслуживание для решения любых проблем с продуктом.

Использование весов не требует большого усилия. Для подключения к питанию необходимо выполнить четыре простых шага. Во-первых, подключите датчики к источнику питания. Во-вторых, включите устройство и выполните калибровку согласно указаниям. В-третьих, поместите объект, который нужно взвесить, под этот датчик нагрузки. Наконец, вес можно либо прочитать на SOP датчик нагрузки дисплее или передать беспроводным способом на другие устройства.

При покупке датчика нагрузки для наших промышленных нужд следует учитывать несколько факторов. Компания должна иметь отличную репутацию в плане качества и обслуживания клиентов. Например, аналоговый усилитель SOP компрессионный датчик нагрузки обычно оценивается по трем критериям. К ним относятся долговечность и точность данных; следовательно, он может служить долго без поломок. Предоставление производителем гарантий и хорошей технической поддержки также должно повышать удовлетворенность потребителей.