No pesagem industrial, o transmissor de célula de carga é um dos componentes mais importantes que preenche a lacuna entre a medição de força física e a análise de dados digitais. Estes SOP transmissor de célula de carga convertem sinais elétricos minúsculos produzidos pelas células de carga que detectam peso ou força em informações legíveis e ações que ajudam a otimizar processos nas indústrias, melhorando a produtividade enquanto garantem que a precisão não seja comprometida. À medida que a tecnologia avança, o desenvolvimento futuro dos transmissores de células de carga melhorará a integração; isso significa que eles podem ser usados para monitorar, controlar e otimizar o desempenho em diferentes operações industriais.

O futuro da pesagem industrial parece promissor com novos desenvolvimentos em transmissores de células de carga esperados em breve; tais dispositivos utilizarão tecnologias de ponta como IoT, IA entre outras, além de adotar protocolos de conectividade mais aprimorados. Tal SOP cÉLULA DE CARGA permitirá a transferência instantânea de dados, permitindo que as empresas respondam rapidamente às mudanças, prevejam requisitos de manutenção e evitem tempos de inatividade. Além disso, os designs futuros visam economizar energia sem comprometer sua capacidade de funcionar eficientemente, tornando-os mais adequados para configurações altamente compactas onde o espaço é limitado, mas a complexidade aumenta dia após dia; assim criando balanças dinâmicas e sustentáveis que estão alinhadas com os princípios da quarta revolução industrial.

O monitoramento remoto tornou-se possível graças a modelos avançados desses gadgets habilitados para wireless, combinados com recursos de compatibilidade com nuvem, o que simplificou tudo sobre a supervisão fora do local. Operadores agora conseguem supervisionar processos de qualquer local a qualquer momento, por meio da transmissão contínua de dados de carga sem fio para servidores localizados fora do site ou até mesmo em salas de controle próximas, usando este tipo de SOP. pesar células eles não precisam estar fisicamente presentes lá eles mesmos. Essa inovação torna-se muito essencial, especialmente ao lidar com ambientes perigosos com mínima presença humana ou operações em larga escala distribuídas por uma ampla área geográfica, exigindo muitos pontos de medição simultaneamente. Com algoritmos complexos de criptografia empregados durante a fase de configuração, juntamente com mecanismos robustos de verificação de integridade colocados em prática enquanto transferem pela rede, as preocupações de segurança entre as pessoas que trabalham nessas áreas onde essas máquinas foram instaladas são completamente resolvidas porque isso garante que os dados recebidos não foram alterados antes de chegarem ao destino. Isso permite que as indústrias tomem decisões rápidas com base em informações precisas e atualizadas, otimizando o uso dos recursos enquanto melhora a segurança no trabalho.

Se você deseja otimizar a eficiência, então transmissores de células de carga devem fazer parte do seu sistema de controle de processo, pois eles oferecem leituras de peso oportunas e precisas. Por exemplo, na área de manufatura, a produção em lote torna-se mais precisa, reduzindo o nível de desperdício e garantindo uniformidade na saída durante toda a cadeia de processos. Na indústria de logística, isso melhora a distribuição de cargas, resultando em atividades de carregamento ou descarregamento mais eficientes em vários pontos, para que veículos não transportem pesos excessivos além de suas capacidades, reduzindo o desgaste das estradas entre outras coisas. Além disso, integrando esses dois SOP um transdutor de força juntos é possível automatizar respostas com base nos pesos fornecidos, acionando alarmes, ajustando velocidades e alimentações, alterando parâmetros envolvidos em diferentes estágios, reduzindo intervenções manuais e levando a uma melhoria geral nos níveis de produtividade alcançados dentro de um ambiente empresarial.

CÉLULA DE CARGA transmissores que operam em condições adversas exigem robustez para funcionarem de forma eficaz em ambientes industriais agressivos onde essas medições são necessárias. SOP sensor de pressão deveriam ser resistentes à umidade, vibrações e interferência eletromagnética, além de serem capazes de suportar temperaturas extremamente altas ou baixas sem afetar suas margens de precisão, as quais podem variar dependendo do tipo de metal usado durante a construção; a ciência dos materiais, como ligas resistentes à corrosão, mais métodos avançados de vedação ajudam a alcançar durabilidade, longevidade e proteção, mesmo quando expostos a elementos nocivos; além disso, recursos de auto verificação permitem monitoramento contínuo para detecção precoce de falhas, promovendo ainda mais estratégias voltadas para a manutenção preditiva, garantindo a confiabilidade das ferramentas usadas e mantendo os padrões de qualidade em diversos setores.

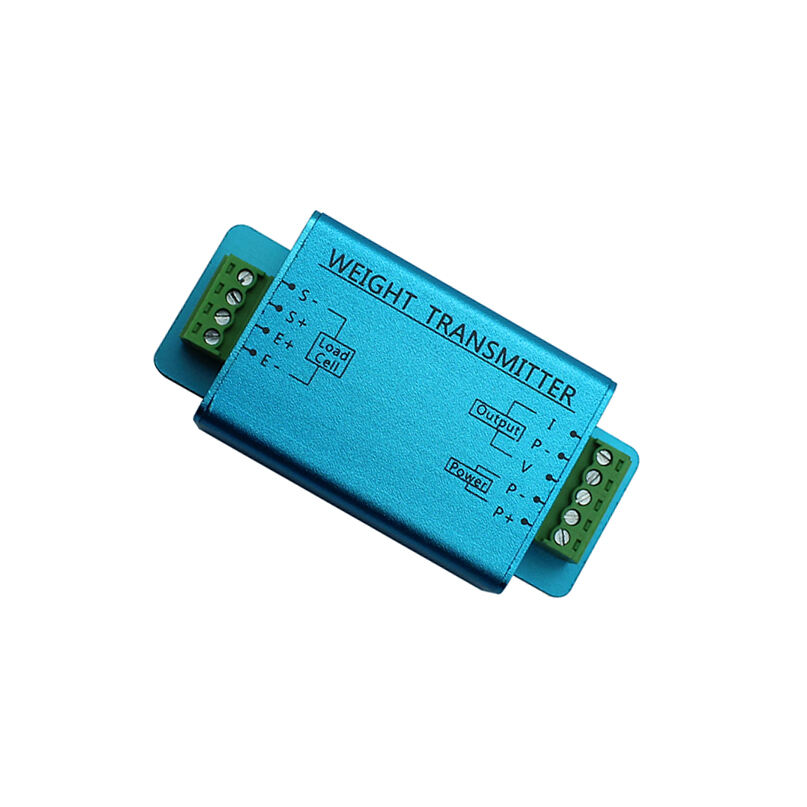

Nossos principais produtos são compostos por diferentes tipos de sensores, tais CÉLULA DE CARGA transmissor sensor de deslocamento sensor de fio de tração Sensor LVDT , célula de carga, sensor de torque, sensor magnético, sensor de pressão, etc. Oferecemos serviços OEM/ODM dependendo das necessidades do cliente.

Oferecemos embalagem segura e protegida, envio acelerado de cada item, com entrega em 2 dias para produtos em estoque CÉLULA DE CARGA transmissor Há vários tipos de serviços de entrega para o cliente escolher. Após a remessa, você receberá as informações de rastreamento.

Nossa empresa é certificada pelo CE, RoHS, ISO9001, bem como outras certificações. Nossos produtos passam por testes rigorosos antes da entrega. A SOP também oferece engenheiros para serviços pós-venda CÉLULA DE CARGA transmissor quaisquer problemas com o produto.

SOP é uma empresa líder CÉLULA DE CARGA transmissor tem mais de 20 anos de experiência em fabricação, trabalhou com mais de 500 clientes ao redor do mundo. SOP é uma empresa reconhecida e atua no desenvolvimento, pesquisa e produção de diversos tipos de sensores.