Let's talk about Draw Wire Sensors and why they're pretty important in industries these days. If you've ever worked with automation or machinery, you already know how crucial it is to measure position and distance really accurately. That’s where these sensors come in—they’ve actually become quite popular because they’re both reliable and tough. You might also hear them called string pots or cable extension transducers—they’re super versatile and find a home in lots of different sectors.

So, what exactly is a Draw Wire Sensor?

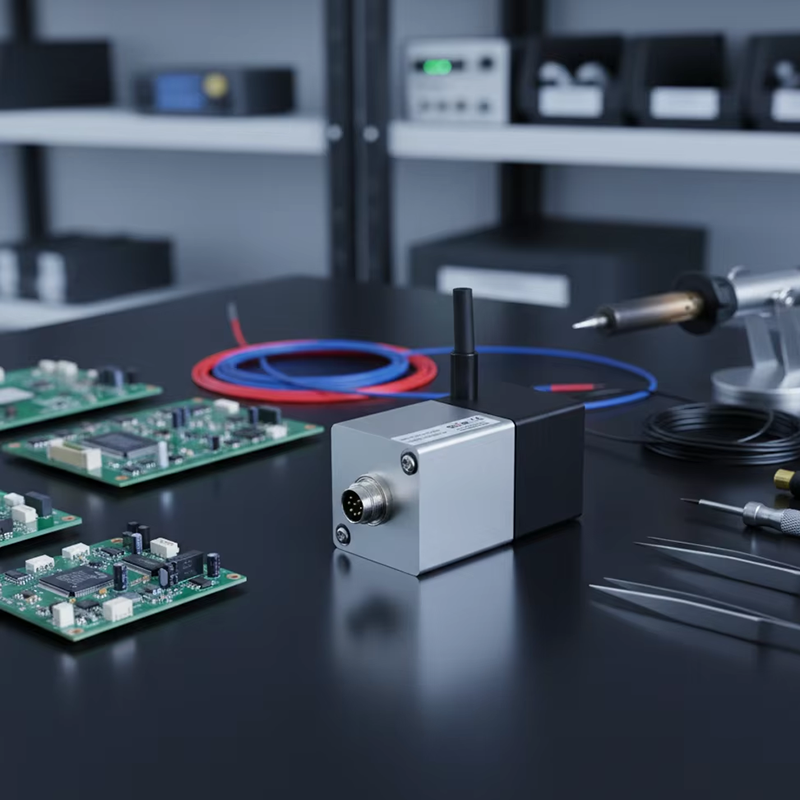

Think of it as a device that measures how far something has moved in a straight line. It does this using a wire that winds and unwinds as the object moves. When something shifts position, the wire either extends or retracts on a small drum inside the sensor. This drum is connected to a component like a potentiometer or an encoder, which translates this movement into an electrical signal. Basically, it turns physical movement into data that you can use to measure that distance pretty precisely.

What makes these sensors stand out?

1. Super Accurate: They’re known for high precision—like catching those tiny position changes. Usually, their accuracy is within 0.01% to 0.1% of their full scale, depending on what you need.

2. Built to Last: These sensors are made from sturdy materials, so they can handle some rough environments—think heavy machinery or factory floors—and still keep going strong.

3. Really Flexible: No matter if you’re working in a small lab or on massive industrial machines, these sensors fit right in. They’re perfect for things like monitoring the position of robotic arms, checking levels in silos, or controlling hydraulic systems.

Where do we see them in action?

- In Manufacturing: They help keep CNC machines and other industrial equipment precisely aligned.

- Construction Gear: They’re used in cranes and excavators to keep track of movement, making sure everything’s safe and in control.

- Automation & Robots: For robots or automated guided vehicles, these sensors give important feedback about position, so everything runs smoothly.

- Aerospace & Defense: In those fields, precision is everything—testing landing gear or running simulations often needs these sensors.

- Medical Devices: Even in healthcare, like MRI machines or patient positioning tools, accurate measurement counts, and draw wire sensors help deliver that precision.

To sum up...

Draw Wire Sensors are a real staple when it comes to measuring things accurately. Their tough build, adaptability, and precision make them a must-have in many industries. As technology keeps evolving, you’ll see these sensors playing an even bigger role in making complex mechanical systems more efficient and safer. Whether you're building advanced robots or just making sure heavy equipment stays on point, investing in good, reliable draw wire sensors can really make a difference in getting accurate, dependable data.