Kao inženjer koji je proveo godine na tvorničkim podovima i u laboratorijima za istraživanje i razvoj, osobno sam svjedočio kako jedan jedini alat može uspjeti ili neuspjeti proizvodnu liniju. Danas ćemo govoriti o osjetilac dinamičnog valjka — netaknutim herojima preciznog mjerenja. Ovi uređaji ne samo da prikupljaju podatke; oni omogućuju proboje u industrijama gdje svaki newton-metar ima značaja. Evo gdje su nezaobilazni.

1. Proizvodnja automobila: srce montažnih linija

U automobilskim tvornicama senzori nadziru okretni moment u stvarnom vremenu tijekom sklopa motora, osiguravajući da su vijci pritegnuti točno prema specifikacijama. Zamislite robotsku ruku koja instalira klipove — dinamički senzor okretnog momenta otkriva najmanje promjene sile, sprječavajući skupe povrate proizvoda. Ova tehnologija nije samo pitanje kontrole kvalitete; radi se o izgradnji povjerenja u svaki vozilo koje napušta traku.

2. Zrakoplovstvo: Inženjering izvan granica

Zrakoplovi zahtijevaju senzore koji podnose ekstremne uvjete. Na primjer, tijekom testiranja turbine, dinamički senzori okretnog momenta mjeri rotacijske sile bez greške, čak i u uvjetima visoke vibracije. Njihova izdržljivost nije po želji — to je lifeline za sigurnosno kritične sustave poput mehanizama sustava za slijetanje.

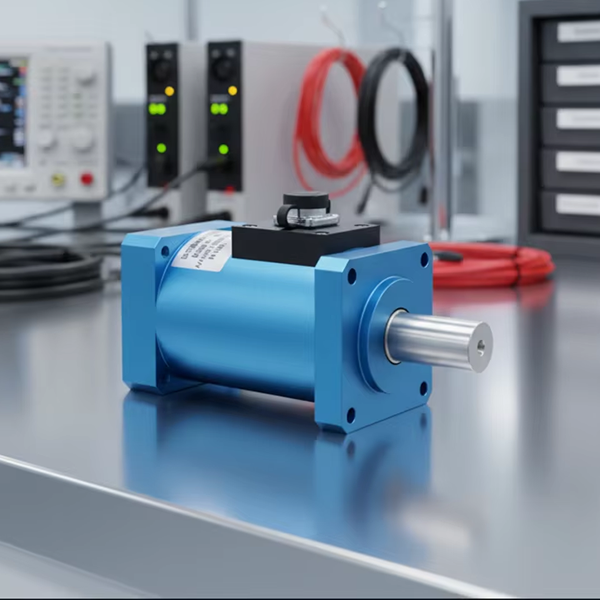

3. Industrijska automatizacija: Leđa pametnih tvornica

Robotske ruke u automatiziranim skladištima oslanjaju se na ove senzore za preciznu povratnu informaciju o sili. Zamislite robota koji sklapa delikatnu elektroniku — senzor dinamički prilagođava okretni moment, imitirajući ljudski dodir. Ova prilagodljivost transformira učinkovitost, smanjujući vrijeme nerada i otpad.

4. Energija: Pokretanje budućnosti

Vjetroelektrane i naftne platforme rade u teškim uvjetima, gdje kolebanja okretnog momenta mogu signalizirati kvar opreme. Senzori ovdje djeluju kao sustavi ranog upozorenja, otkrivajući abnormalne sile u stvarnom vremenu kako bi spriječili katastrofalne kvarove. Njihova izdržljivost osigurava pouzdanost tamo gdje su popravci skupi i rizični.

5. Medicinska uređaji: Preciznost susreće inovaciju

U robotskoj kirurgiji, osjetilac dinamičnog valjka omogućuju delikatne postupke pružanjem povratne informacije o sili u stvarnom vremenu. Suptilni pokreti kirurga prenose se u precizna podešavanja instrumenta, poboljšavajući ishode za pacijente. Ova kombinacija inženjerstva i medicine ponovno definira ono što je moguće.

Zašto je važno

Osjetilac dinamičnog valjka senzori nisu samo alati — oni omogućuju napredak. Od automobila do operacijskih dvorana, njihova sposobnost mjerenja i prilagodbe tiho pokreće inovacije. Dok industrije pomaču granice, ti senzori osiguravaju da se preciznost ne žrtvuje radi brzine.

Jeste li ikada radili s senzorima okretnog momenta u svojoj oblasti? Podijelite svoja iskustva — volio/la bih čuti kako su oblikovali vaše projekte!