Understanding Modern Proximity Detection Technologies

Proximity sensor technology has revolutionized how machines and devices interact with their surroundings. These sophisticated detection systems serve as the electronic eyes and ears in countless applications, from manufacturing automation to everyday consumer electronics. By accurately detecting the presence or absence of objects without physical contact, proximity sensors have become indispensable in today's technological landscape.

The evolution of proximity sensor detection types has led to increasingly precise and reliable sensing capabilities. Each detection method offers unique advantages and specific use cases, making it crucial for engineers and system designers to understand their distinct characteristics. As we explore the various detection technologies, you'll discover how each type contributes to the advancement of automated systems and smart devices.

Inductive Proximity Sensing Technology

Operating Principles of Inductive Detection

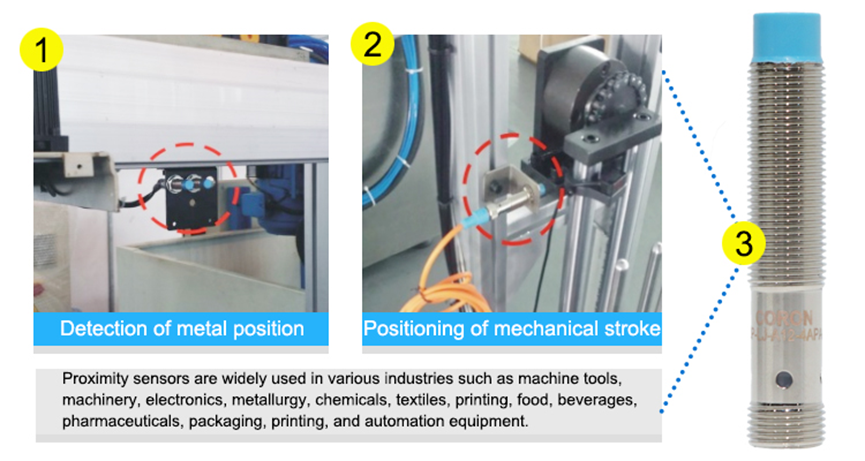

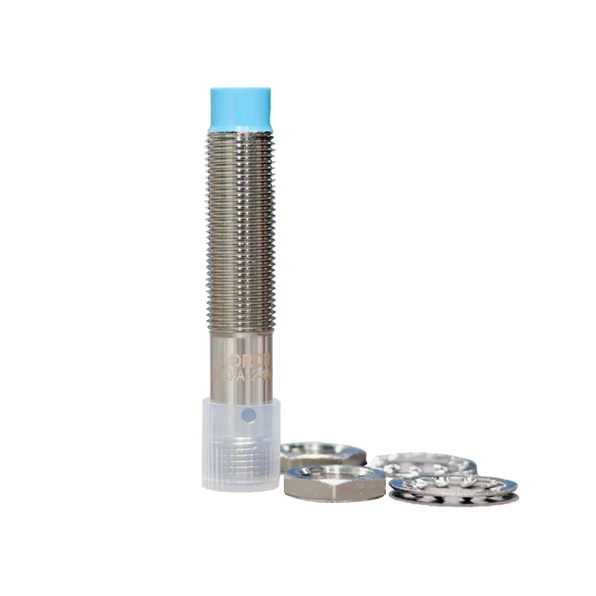

Inductive proximity sensors operate on electromagnetic principles, generating a high-frequency electromagnetic field that interacts with conductive targets. When a metallic object enters this field, eddy currents are induced in the target, causing a loss of energy in the sensor's oscillator circuit. This energy loss triggers the sensor's output, indicating the presence of the target object.

The detection process relies on sophisticated circuitry that monitors these electromagnetic interactions with exceptional precision. Modern inductive sensors can detect metallic objects at distances ranging from a few millimeters to several centimeters, depending on the sensor's size and the target's material properties.

Applications and Advantages

Industrial manufacturing particularly benefits from inductive proximity sensor detection types, where they excel in metal detection and positioning applications. These sensors prove invaluable in assembly lines, packaging machinery, and quality control systems where reliable metal detection is crucial.

The key advantages of inductive sensing include immunity to environmental contaminants, excellent temperature stability, and long operational life due to their non-contact operation. Their ability to function in harsh industrial environments while maintaining accurate detection makes them a preferred choice for many automated manufacturing processes.

Capacitive Detection Systems

Fundamental Operating Mechanisms

Capacitive proximity sensors utilize changes in electrical capacitance to detect objects. They generate an electrostatic field and monitor changes in capacitance when objects enter this field. Unlike inductive sensors, capacitive types can detect both metallic and non-metallic materials, including plastics, liquids, and organic materials.

The detection principle involves creating an electrical field between the sensor's electrodes. When an object enters this field, it affects the dielectric properties, causing a measurable change in capacitance. Advanced signal processing algorithms interpret these changes to determine object presence and characteristics.

Versatility in Material Detection

The versatility of capacitive proximity sensor detection types makes them ideal for level sensing, material discrimination, and presence detection in various industries. They excel in applications where detecting non-metallic materials is essential, such as food processing, pharmaceutical manufacturing, and chemical handling.

These sensors can detect through non-metallic containers, making them perfect for level monitoring in plastic tanks or detecting products through packaging materials. Their ability to distinguish between different materials based on dielectric properties adds another dimension to their utility.

Photoelectric Sensing Technology

Light-Based Detection Methods

Photoelectric proximity sensors employ light beams for object detection, typically using infrared or visible light sources. These sensors come in several configurations, including through-beam, retro-reflective, and diffuse reflection types, each suited for different application requirements.

The detection process involves emitting light and analyzing how it interacts with target objects. Modern photoelectric sensors incorporate advanced features like background suppression and automatic sensitivity adjustment to enhance reliability and reduce false triggers.

Range and Accuracy Considerations

Among proximity sensor detection types, photoelectric sensors often offer the longest detection ranges, capable of sensing objects several meters away. Their accuracy depends on factors such as target surface properties, ambient lighting conditions, and the specific sensing mode employed.

Advanced photoelectric sensors feature precise timing circuits and sophisticated light modulation techniques to maintain accuracy across varying environmental conditions. This makes them particularly valuable in applications requiring long-range detection or precise object positioning.

Ultrasonic Detection Technology

Sound Wave Principles

Ultrasonic proximity sensors utilize high-frequency sound waves to detect objects. They emit ultrasonic pulses and measure the time taken for echoes to return after reflecting off target objects. This time-of-flight measurement principle enables accurate distance determination and presence detection.

The technology behind ultrasonic detection has evolved significantly, with modern sensors incorporating temperature compensation and advanced signal processing to maintain accuracy under varying conditions.

Environmental Adaptability

One of the key strengths of ultrasonic proximity sensor detection types is their ability to function effectively in challenging environments. They perform reliably in dusty or humid conditions where optical sensors might struggle, making them ideal for outdoor applications and industrial environments.

These sensors excel in applications involving transparent or highly reflective objects, which might pose challenges for other sensing technologies. Their ability to detect objects regardless of color, transparency, or surface finish makes them versatile solutions for diverse detection needs.

Frequently Asked Questions

How Do Environmental Factors Affect Different Proximity Sensor Types?

Environmental factors impact each sensor type differently. Inductive sensors are largely immune to dust and moisture but are affected by strong electromagnetic fields. Capacitive sensors can be influenced by humidity and temperature changes. Photoelectric sensors may be affected by ambient light and dirty environments, while ultrasonic sensors can be impacted by extreme temperature variations and air turbulence.

What Is the Typical Lifespan of Modern Proximity Sensors?

Modern proximity sensors typically have a long operational life, often exceeding 10 million operations. Solid-state sensors like inductive and capacitive types generally last longer than those with mechanical components. Regular maintenance and proper installation can significantly extend sensor lifespan.

Can Multiple Proximity Sensor Types Be Used Together?

Yes, combining different proximity sensor detection types can create more robust and reliable detection systems. For example, using both photoelectric and ultrasonic sensors can provide redundancy and overcome the limitations of each technology. This approach is common in critical applications where detection reliability is paramount.