Introduction

Inductive proximity sensor has become indispensable components in modern industrial automation systems. These contactless detection devices offer numerous technical advantages that make them superior to mechanical switches and other sensing technologies in many applications. This article explores the six core benefits that have established inductive sensors as the preferred choice for metal detection in harsh industrial environments.

1. Non-Contact Operation

Unlike mechanical limit switches that require physical contact, inductive sensors detect metallic objects through electromagnetic fields. This eliminates:

Mechanical wear and tear

Contact bounce issues

Maintenance requirements Typical operational lifespans exceed 10 million cycles, significantly outperforming mechanical alternatives.

2. Exceptional Reliability

Engineered for industrial environments, these sensors demonstrate:

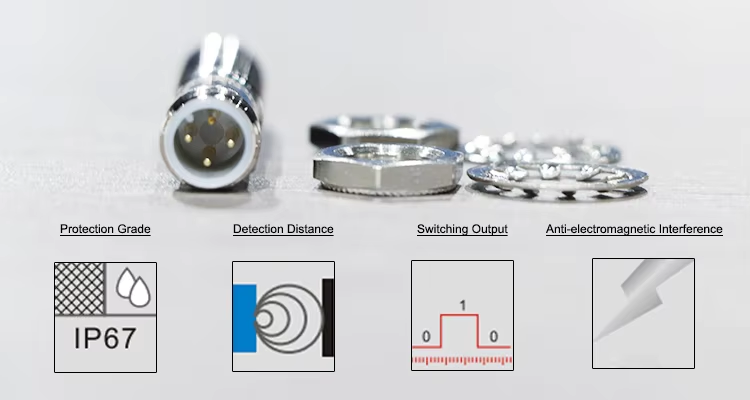

IP67/IP68 protection against dust and water immersion

Resistance to vibration (up to 30G) and shock

Stable performance across temperature ranges (-25°C to +70°C)

Immunity to oil, grease, and other contaminants

3. High-Speed Detection

Modern inductive sensors achieve:

Response times as fast as 0.1ms

Switching frequencies up to 5kHz

Consistent detection at conveyor speeds exceeding 10m/s This enables precise position monitoring in high-speed automation lines.

4. Configuration Flexibility

Manufacturers offer multiple variants to suit diverse applications:

Shielded vs unshielded designs

Various sensing ranges (2mm to 60mm)

Diverse housing materials (nickel-plated brass, stainless steel)

Multiple output configurations (PNP/NPN, NO/NC)

5. Cost-Effective Solution

Compared to alternative technologies:

Lower total cost of ownership (no moving parts to replace)

Reduced downtime for maintenance

Simplified installation (compact form factors)

Energy-efficient operation (typically <1W power consumption)

6. Smart Features in Modern Models

Advanced sensors now incorporate:

IO-Link communication for parameter adjustment

Diagnostic capabilities (switch point monitoring)

LED status indicators

Teach-in functionality for simplified setup

From automotive assembly to food processing, inductive proximity sensors deliver unmatched performance in metal detection applications. Their combination of durability, precision, and cost efficiency continues to drive adoption across industries. As Industry 4.0 evolves, these sensors are integrating smarter features while maintaining their fundamental advantages that have made them industrial staples for decades.