When I first started working in industrial automation, I was fascinated by how machines "knew" their exact position with pinpoint accuracy. Over time, I realized that behind this magic lies a unsung hero: the linear displacement sensor. These devices measure straight-line movement with incredible precision, translating physical motion into electrical signals that control everything from robotic arms to automotive systems. Their market positioning is not just about technology—it’s about solving real-world challenges in industries where even a millimeter’s error can cost millions.

The Core Value: Precision Meets Reliability

Linear displacement sensors are designed to excel in environments where traditional methods fail. Unlike contact-based sensors that wear out over time, non-contact variants (like optical or magnetic types) offer durability by eliminating physical interaction. This makes them ideal for harsh conditions—think extreme temperatures, vibrations, or contamination—common in manufacturing or aerospace applications. For instance, in automotive assembly lines, these sensors ensure robotic arms place components with sub-millimeter accuracy, reducing waste and improving efficiency. Their ability to provide real-time feedback transforms systems from "dumb" machines into intelligent entities that adapt on the fly.

Where They Shine: Industry-Specific Applications

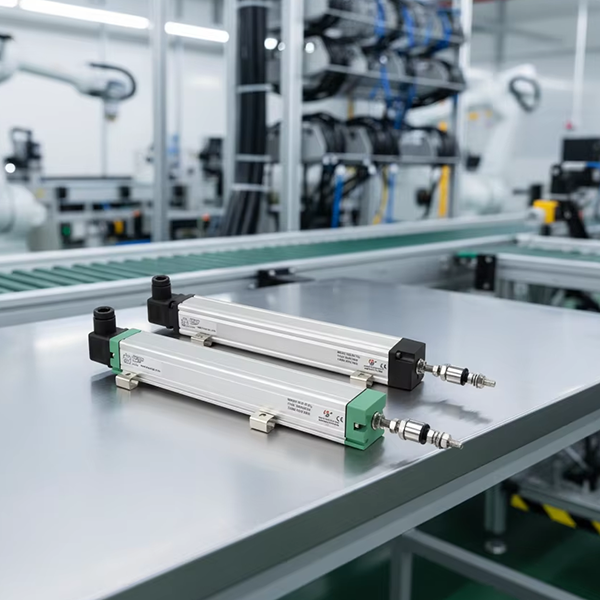

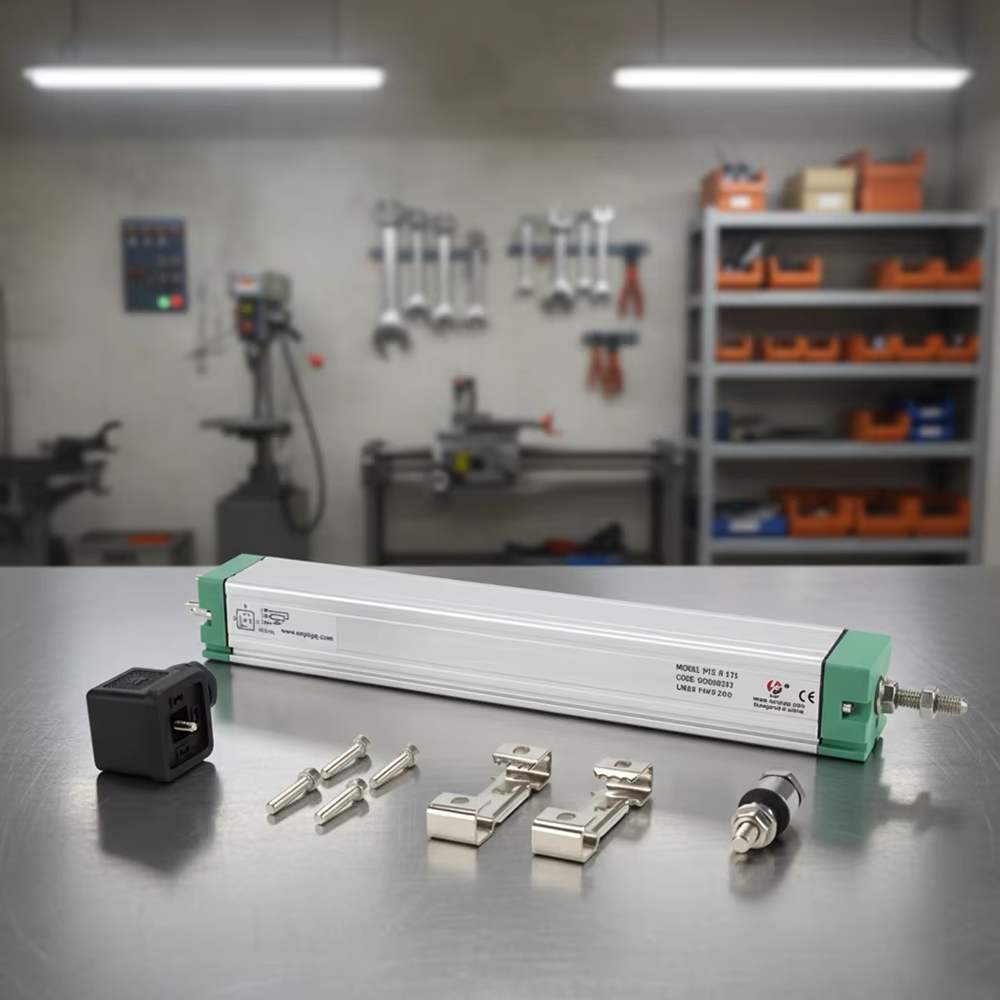

Industrial Automation: In factories, linear sensors are the backbone of precision machinery. They monitor conveyor belt speeds, control robotic movements, and ensure quality checks in production lines. Their high resolution and fast response times prevent costly downtime by detecting deviations before they escalate.

Automotive Sector: From engine testing to autonomous vehicle navigation, these sensors enable accurate position tracking. For example, they measure piston movement in real-time, optimizing fuel efficiency and emissions. The automotive industry’s push toward electrification and automation has further fueled demand, as sensors are critical for safety systems like adaptive cruise control.

Aerospace & Defense: Here, reliability is non-negotiable. Linear sensors are used in flight control surfaces, ensuring aircraft stability by monitoring wing adjustments. Their robustness against environmental stressors makes them indispensable for mission-critical applications.

Healthcare & Consumer Electronics: In medical devices, they assist in precise surgical robot movements, while in smartphones, they enable touchscreen responsiveness. Their miniaturization has opened doors to wearables and IoT devices, where space and power constraints are tight.

Market Trends: Growth Drivers and Challenges

The global market for linear displacement sensors is expanding rapidly, driven by automation’s surge across industries. Key trends include:

Non-Contact Dominance: Optical and magnetic sensors are gaining traction due to their longevity and precision, though they come at a higher initial cost. Industries are willing to invest for long-term savings in maintenance and accuracy.

Integration with AI: Smart sensors now feed data into machine learning models, enabling predictive maintenance. For example, a factory using these sensors can anticipate equipment failures before they occur, minimizing disruptions.

Challenges Ahead: Despite advancements, issues like signal interference in noisy environments or the need for calibration in extreme conditions persist. Manufacturers are innovating with shielded designs and self-calibrating algorithms to mitigate these hurdles.

Why It Matters: Beyond Technology

Positioning linear displacement sensors in the market isn’t just about specs—it’s about trust. Engineers and businesses rely on them because they deliver consistent results under pressure. Take a packaging plant: a sensor’s failure could halt production, costing thousands per hour. That’s why industries prioritize suppliers with proven track records, often opting for established brands known for reliability over cheaper alternatives.

As someone who’s seen these sensors evolve from bulky components to sleek, smart devices, I’m excited about their future. With industries like renewable energy and robotics booming, their role will only grow. For businesses, investing in the right sensor isn’t a expense—it’s a strategic move toward efficiency and innovation.

Final Thought: In a world where precision is power, linear displacement sensors are the silent enablers. Whether you’re designing a robot or optimizing a factory, understanding their market positioning helps you choose the tool that turns vision into reality.