Understanding LVDT Sensors in Modern Industrial Monitoring

Linear Variable Differential Transformers (LVDT sensors) have emerged as a cornerstone technology in industrial monitoring applications. These sophisticated measurement devices offer unparalleled precision and reliability for continuous position monitoring across various industrial sectors. As industries increasingly demand robust, long-term monitoring solutions, LVDT sensors have proven their worth through consistent performance and durability.

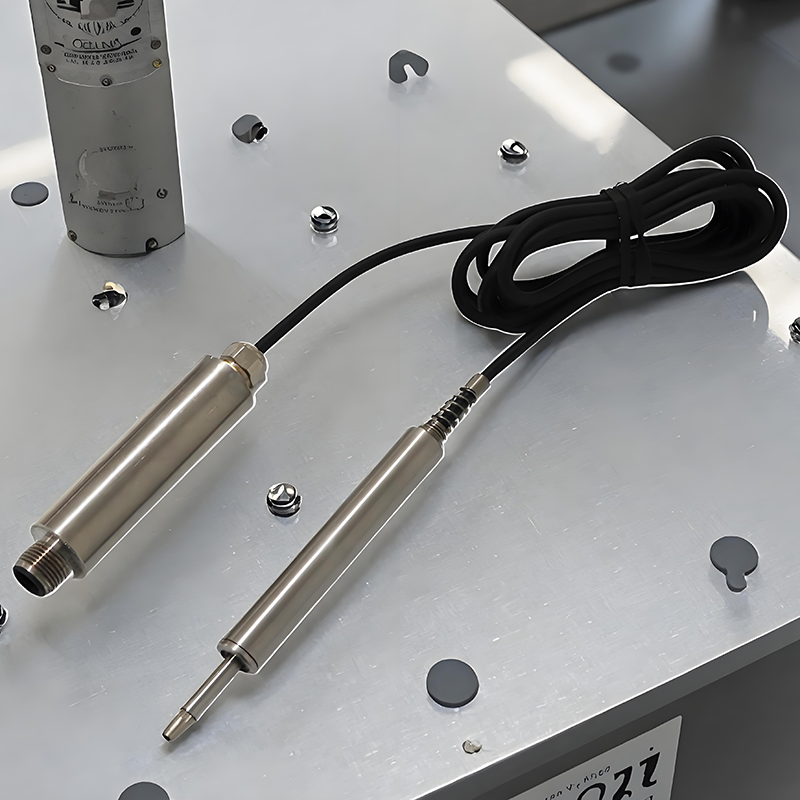

The fundamental principles behind LVDT sensor operation make them particularly well-suited for extended monitoring scenarios. These sensors utilize electromagnetic coupling between primary and secondary coils to generate precise linear displacement measurements, without physical contact between the moving and stationary parts. This contactless operation is a key factor in their longevity and reliability for continuous monitoring applications.

Core Benefits of LVDT Sensors for Extended Monitoring

Exceptional Durability and Reliability

LVDT sensors demonstrate remarkable durability in long-term monitoring applications. Their robust construction and minimal moving parts contribute to an extended operational lifespan, often exceeding millions of cycles without significant degradation in performance. The absence of physical contact between the core and coil assembly eliminates wear and tear, making them ideal for continuous operation in demanding industrial environments.

The reliability of LVDT sensors is further enhanced by their resistance to environmental factors. These sensors can operate effectively in extreme temperatures, high humidity, and challenging industrial conditions. Their sealed construction protects internal components from dust, moisture, and other contaminants that could compromise measurement accuracy over time.

Precision and Stability Over Time

One of the most compelling advantages of LVDT sensors in long-term monitoring is their ability to maintain measurement accuracy over extended periods. Unlike other position sensors that may drift or require frequent recalibration, LVDT sensors provide consistent, repeatable measurements throughout their operational life. This stability is crucial for applications requiring precise monitoring over months or years.

The inherent design of LVDT sensors contributes to their measurement stability. The ratiometric nature of their output signal helps minimize the effects of temperature variations and power supply fluctuations, ensuring reliable measurements even in changing environmental conditions.

Industrial Applications and Implementation

Critical Monitoring Scenarios

LVDT sensors excel in various industrial monitoring applications where continuous, reliable measurement is essential. In power generation facilities, these sensors monitor turbine valve positions and equipment alignment. Manufacturing plants utilize LVDT sensors for quality control and process automation, while civil engineering projects employ them for structural health monitoring.

The aerospace industry particularly benefits from LVDT sensor technology for monitoring flight control surfaces and landing gear positions. These applications demonstrate the sensor's capability to provide critical measurements in high-stakes environments where failure is not an option.

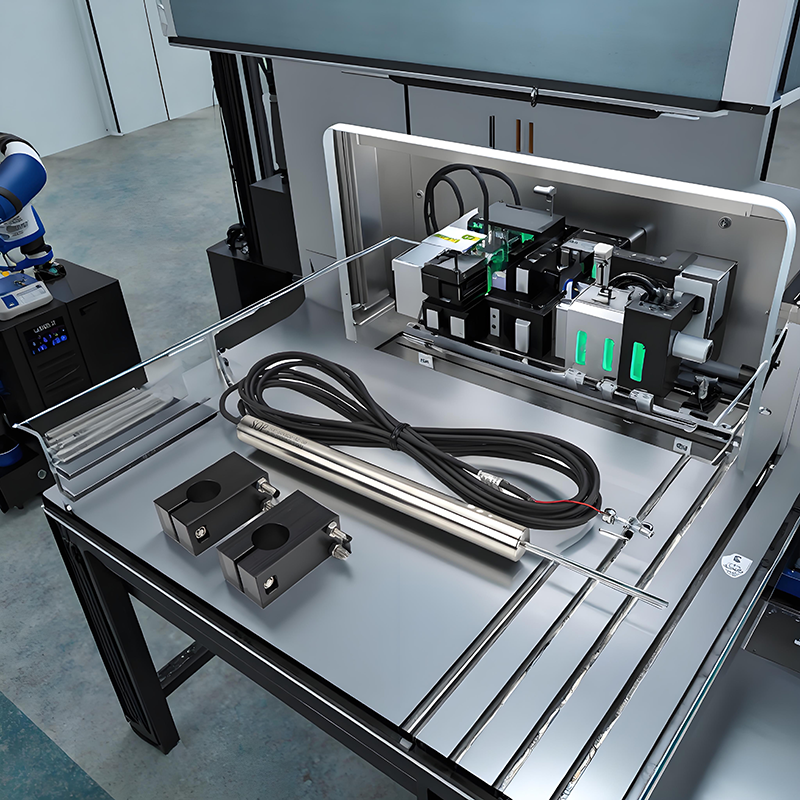

Integration and Maintenance Considerations

Implementing LVDT sensors for long-term monitoring requires careful consideration of installation and maintenance factors. Proper mounting and alignment are crucial for optimal performance, while environmental protection measures ensure longevity. Regular system checks and preventive maintenance schedules help maintain measurement accuracy and system reliability.

Modern LVDT sensors often feature digital interfaces and diagnostic capabilities, simplifying integration with existing monitoring systems. These advanced features enable remote monitoring and early detection of potential issues, reducing maintenance requirements and improving overall system reliability.

Environmental Factors and Performance

Temperature and Humidity Resistance

LVDT sensors demonstrate exceptional performance across a wide range of environmental conditions. Their operating temperature range typically spans from -40°C to +150°C, making them suitable for both indoor and outdoor applications. The hermetically sealed construction of quality LVDT sensors provides excellent protection against humidity and moisture, ensuring consistent operation in challenging environments.

Advanced manufacturing techniques and materials selection further enhance the environmental resistance of modern LVDT sensors. Special coatings and treatments can extend their operational capabilities in corrosive or hazardous environments, making them ideal for long-term monitoring in diverse industrial settings.

Vibration and Shock Tolerance

The robust construction of LVDT sensors makes them highly resistant to mechanical shock and vibration. This characteristic is particularly valuable in industrial environments where equipment vibration and mechanical stress are common. The sensor's ability to maintain accuracy under these conditions ensures reliable long-term monitoring in dynamic applications.

Design features such as reinforced housings and specialized mounting options further enhance the sensor's resistance to external forces. This resilience contributes to their suitability for long-term monitoring in applications subject to continuous mechanical stress.

Future Trends and Technological Advances

Smart Sensor Integration

The evolution of LVDT sensor technology continues with the integration of smart features and Industry 4.0 capabilities. Modern sensors increasingly incorporate built-in diagnostics, digital communication protocols, and advanced signal processing. These developments enhance their utility for long-term monitoring applications by providing additional data and improving maintenance efficiency.

Emerging technologies such as wireless connectivity and IoT integration are expanding the capabilities of LVDT sensors in monitoring applications. These advances enable real-time data collection, remote monitoring, and predictive maintenance strategies, further solidifying their position as a preferred choice for long-term monitoring solutions.

Enhanced Performance Capabilities

Ongoing research and development in LVDT sensor technology focus on improving measurement resolution, expanding operating ranges, and reducing power consumption. These advancements are making LVDT sensors even more attractive for long-term monitoring applications, particularly in remote or battery-powered installations.

New materials and manufacturing techniques are also contributing to enhanced sensor performance and reliability. These improvements result in sensors with greater accuracy, improved temperature stability, and extended service life, further validating their suitability for long-term monitoring applications.

Frequently Asked Questions

How long can an LVDT sensor operate continuously?

LVDT sensors are designed for continuous operation and can function reliably for many years when properly installed and maintained. Their contactless operation and robust construction typically allow for millions of cycles without significant performance degradation, making them ideal for long-term monitoring applications.

What maintenance is required for LVDT sensors in long-term monitoring?

LVDT sensors require minimal maintenance due to their robust design. However, periodic inspection of mounting hardware, electrical connections, and calibration verification is recommended. Most maintenance activities focus on ensuring the surrounding installation remains secure and clean rather than the sensor itself.

Can LVDT sensors maintain accuracy in harsh industrial environments?

Yes, LVDT sensors are specifically designed to maintain their accuracy in challenging industrial conditions. Their sealed construction, temperature compensation features, and resistance to vibration and shock ensure reliable performance even in harsh environments. Many LVDT sensors are rated for extreme temperatures, high humidity, and exposure to industrial contaminants.