Linear position sensors are essential devices used in various industries to measure the displacement of an object along a straight path. But how exactly do they work? Let’s break it down simply.

What is a Linear Position Sensor?

A linear position sensor detects the position of an object in a linear motion—think of it as a way to measure how far an object has moved in a straight line. These sensors can operate using different technologies, including potentiometric, capacitive, and inductive methods.

Working Principle

Mechanism: Most linear position sensors operate via a sensing element that can detect changes in position. This could be a resistive element, a capacitive plate, or inductive coils.

Displacement Detection: As the object moves, it alters the physical characteristics (like resistance or capacitance) of the sensor. For instance, in a potentiometric linear sensor, a slider moves along a resistive strip. This movement changes the resistance value, which can then be converted into a voltage signal proportional to the position.

Signal Conversion: Once the position change is detected, the sensor outputs a signal. This output may be analog (varying voltage) or digital (specific position data). The choice between these outputs depends on the application and desired accuracy.

Feedback Loop: In many applications, the output from the sensor is fed back into a control system. This creates a closed loop, allowing for real-time position monitoring and adjustment, essential in automated systems.

Types of Linear Position Sensors

Resistive Sensors: Commonly used for lower precision applications, these sensors rely on variable resistance to determine position.

Inductive Sensors: These utilize coils and magnetic fields, offering high accuracy and durability, making them suitable for demanding environments.

Capacitive Sensors: These sensors measure changes in capacitance caused by shifting position, often used in applications requiring high sensitivity.

Applications

Linear position sensors have a wide array of applications, including:

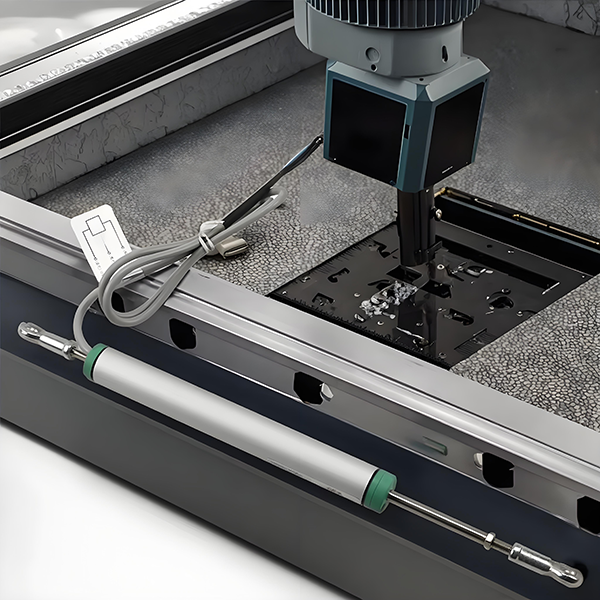

Manufacturing: For monitoring the positions of moving parts in machinery.

Automotive: In systems like throttle position sensors to optimize performance.

Aerospace: Measuring control surface positions for enhanced flight control.

Robotics: Facilitating precise movement and positioning in robotic arms.

In summary, linear position sensors are crucial for accurately measuring straight-line displacement across numerous applications. Their working principle revolves around detecting changes in physical properties that correlate to position, producing a signal that can be utilized in various control systems. As industries continue to advance, the role of these sensors will only become more significant, driving efficiency and precision in modern technology.