Engineering of Structural Tension Explained

ST: Structural tension is a basic concept in engineering that determines the stability of several structures. When engineers are designing projects, such as bridges or buildings, they always have to consider structural tensility impact in the materials surrounding those works.

Material tug and pull from opposite directions, where two forces equal in proportion pulling against each other form a structural tension. This tension is important in order to gain the stability needed to build sturdy and anti-fragile frameworks withstanding from outside influence.

Choosing the Right Strength of Materials

Engineers must decide what level of strength materials need to be for a structure, say a bridge or highway system because the work load and weight that will bear down upon it is immense. For instance, when it comes to build a bridge that engineers need to estimate how heavy the maximum weight of vehicles it will bear and also predict pressure which is on the building.

Defination of Strain and Tensile Stress

When material is under tension, it deforms and this deformation of material w.r.t force per unit area called as tensile stress. Hooke's Law is a fundamental concept that engineers use to predict how materials will behave under tension and design the product accordingly.

To make tension the structures withstand, engineers adapt it using several strategies (see 1.6 Surfing Tension). One common solution is to make components thicker, less bendy so it doesn't have much give and the risk of stretching minimized. This method is especially common in high-rise buildings or projects with heavy loads on the roof.

Steel and aluminum structures are preferred by engineers worldwide for building structures where world-class strength, stability, and elasticity is warranted due to their high yield strengths nature with capability sustaining massive tension forces without any deformation.

Additional Design & Predictive Tools: for Structural Behavior

Using computer programs, engineers can simulate how a structure will behave when tension is applied to it in the strongest direction. The predictive capability allows them to spot potential weak points early in the design and modify accordingly, leading best possible structural performance.

Structural Integrity is the most important

Structural safety checking is one of the most important practice in engineering to avoid failures that may lead to loss of life. Engineers follow strict safety codes and choose materials carefully to cater for the expected stresses by designing structures that can handle them without failing.

Design and Durability Factors to Be Aware Of

When designing the structure, engineers should take into account factors like wind or seismic forces for proper durability and reliability. The choice of materials and confirmation through the performance testing is a must in building structures for environmental strangeness.

Structural tension is an essential aspect of engineering as it plays a significant role in determining the ability of buildings and infrastructures to resist external forces that could lead deformation or failure. Engineers have to take into account many factors when they design steel in structures, which are ultimately rigid, Set against being truly safe built up with tension.

Creative Alternatives to Structure Design

This technology has provided engineers with new frontiers to develop high strength, lightweight structures in the field of structural design by exploiting composites. With materials like carbon fiber composites and 3D printing, innovative design solutions (and production efficiency) are possible.

Tensile strength of structures compared

Structural issue is one of the most important points for design on tension system. Among these include finite element analysis tools and the shattered of models which determines how structures responds to different forces, leading stresses concentration in order for sustainable design before construction happens.

Engagement of Structural Tension in Order to Create Resilient Constructors

For an engineer to be able to get safety and durability in his construction, he must learn how to travel through structural tension. Engineers can develop structures better and mitigate the risk of collapse because they are free to experience with all new methods, material s,and technologies.

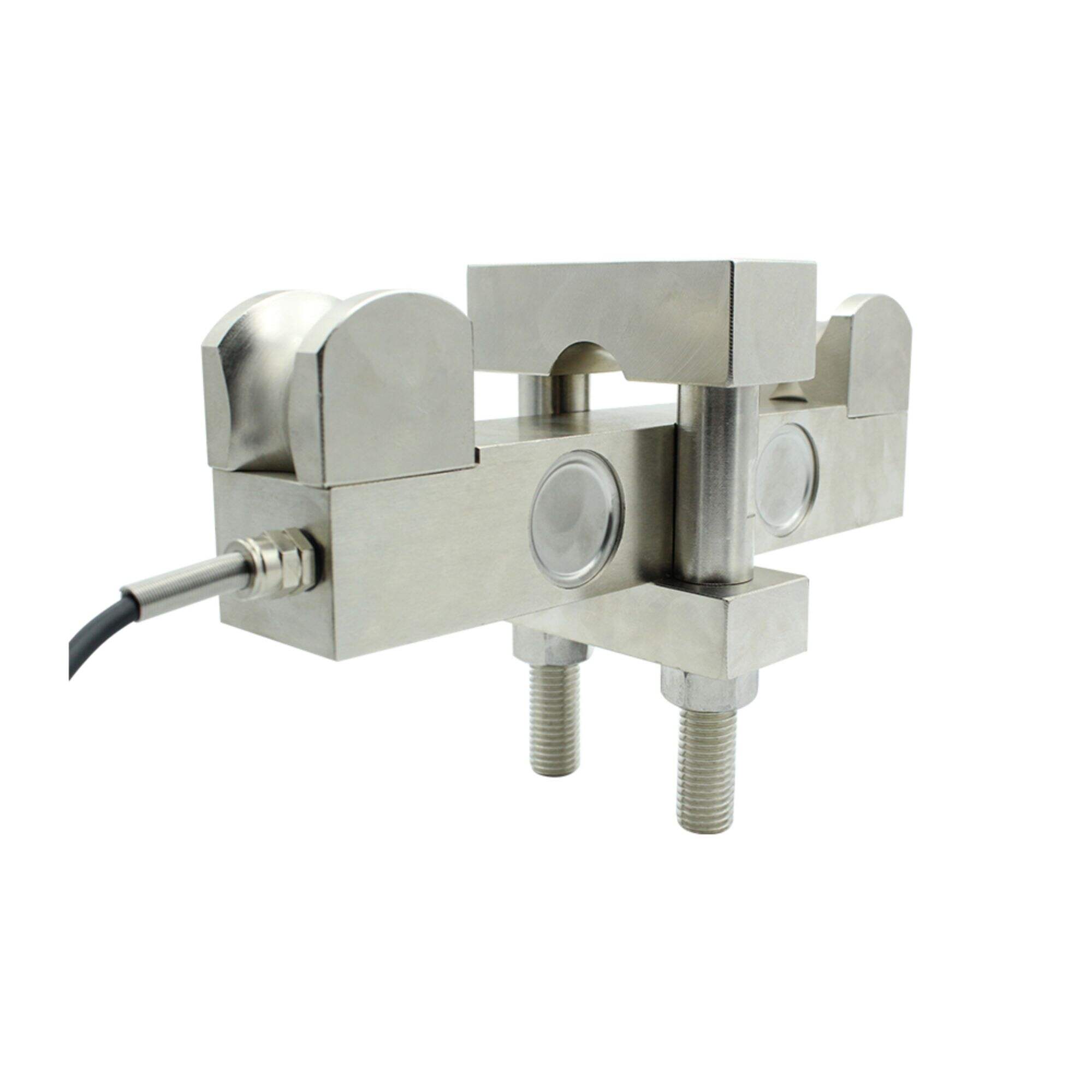

We are accredited by CE, RoHS ISO9001. We ensure every item undergoes a rigorous inspection prior tension load. SOP also has engineers can offer after-sales services solve any problems with the product.

We provide secure reliable tension load each product, and speedy shipping 2 days for stock goods There numerous types of transportation options available customer to choose. Following the delivery you will be provided with tracker details.

Our main products consist of tension load kinds of sensors, such linear displacement sensor, draw wire sensor, load cell, LVDT torsion sensor, pressure sensor, magneto sensor on. We offer OEM/ODM support according to the customer's requirements

SOP has over 20 years production experience has worked with more 5000 global customers, which is tension load company manufactures high-tech products and is involved in research, development and production, as well as sale and servicing of various kinds of sensors.