Jobs like public transportation, construction and agriculture hinge upon the measurement of wheel or axle weights. Getting weight right is the key to keeping everything safe and legal, but also saving money. The way we measure weight is undergoing a cool revolution called spoke load cells

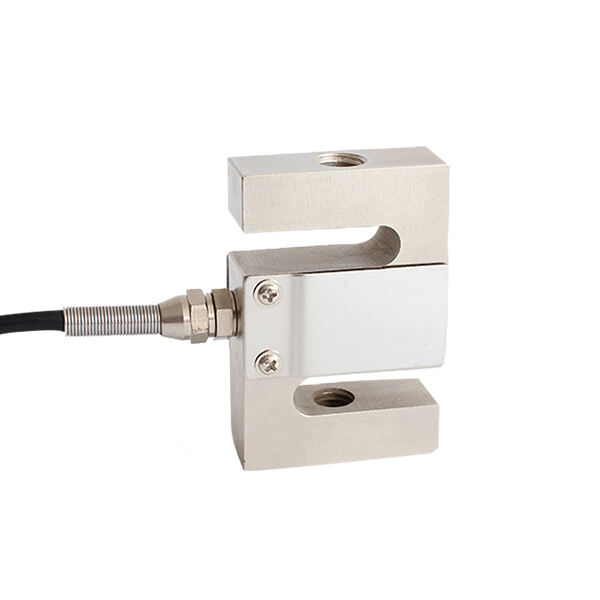

Also known as wheel or axle load cells, spoke lander is a special tool for measuring the weight of tires and axles. These SOP load sensor are well-designed even to distribute the weight evenly such that your measurements can always be sound and reliable

The new load cells are much easier to put in place and maintain than the older ones. Less chance of breaking as the design is such that this technology makes load cell more robust in its physical activity.

Evaluating the weight of big heavy things is crucial and every pound in that category counts such as machines peso or any other really heavyweight. Spoke Load Cell technology is also improving this checking by providing precise weight measurements to their affluent clients. The SOP sensor load cell are designed uniquely in a way to distribute the weight across evenly, so they provide accurate measurements even with heavy things

In wide load-carrying operation, a new and economical approach to test blunt instruments using Spoke Load Cells. These are constructed to withstand high temperatures, harsh environments and other chemicals such as moisture oils etc.

Spoke load cells are perhaps the most famous sort of measurement sensors which guarantee precise weight readings for a wide range of applications in fields like horticulture, development and transportation. This technology was designed to remedy many of the issues that plagued older load cells when weighing very large and heavy items

Installation and maintenance of these SOP load amplifier cells are simple, which makes them a cost-effective method of measuring weight that is next to no care. With the ability to withstand weather, carry heavy loads and work with harsh chemicals your measurements will stay right on every time.

Weight is critical in an industry that moves huge amounts of matter over long distances every day by rail. The railway industry has some limitations on the older load cells. These restrictions can be overcome with the help of spoke load cells, which offer precise and reliable weight monitoring thus decreasing risks such as accidents or cargo damage

Railway Load Cells Railway Load cells designed for railway applications that are: Made to handle tough environments involving large shocks and vibrations, high temperature fluctuations. SOP load cell weighing systems are extremely low maintenance, keeping downtime and costs to a minimum.

SOP is a manufacturer high-tech spoke load cell that has over 20 years' experience in the field production. It has worked with more 500 clients around the world. SOP is a reputable company is engaged in the research, development and production of various types of sensors.

Our company certified by CE, RoHS, ISO9001 and various certifications. Prior to shipping, check every product. Additionally, SOP professional engineers provide after sales service to resolve product use and other spoke load cell.

Our main products consist of spoke load cell kinds of sensors, such linear displacement sensor, draw wire sensor, load cell, LVDT torsion sensor, pressure sensor, magneto sensor on. We offer OEM/ODM support according to the customer's requirements

Customers can select from range of transportation services. We provide secure packaging speedy delivery all stock goods. Tracking information be spoke load cell after goods are shipped.