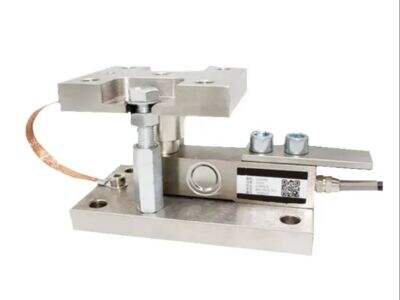

small pressure sensor

Small pressure sensors are cutting-edge measurement devices designed to detect and monitor pressure changes in various environments with exceptional precision. These compact devices integrate advanced sensing technology within a miniaturized form factor, typically measuring just a few millimeters in size. The sensors utilize innovative piezoresistive or capacitive sensing elements that transform pressure variations into electrical signals, enabling accurate real-time monitoring and data collection. The small pressure sensor's design prioritizes both functionality and space efficiency, making it ideal for applications where size constraints are crucial. These sensors can measure a wide range of pressures, from vacuum conditions to high-pressure environments, while maintaining accuracy throughout their operational lifetime. They feature built-in temperature compensation mechanisms to ensure reliable readings across varying environmental conditions. The sensor's construction typically includes a robust housing that protects the sensitive components while allowing for easy integration into larger systems. These devices often incorporate digital output options, making them compatible with modern control systems and IoT applications. The versatility of small pressure sensors makes them essential components in medical devices, automotive systems, industrial automation, and consumer electronics, where precise pressure monitoring is crucial for optimal performance and safety.